24

Maintenance

Mai

n

t

enance

7.3.1 Oil Change

The oil should be changed after the first 200 operating hours for new bearings and then every 2000 operating hours or 3

months, depending on which comes first.

• Before changing the oil, the pump must be started in order to fluidize the oil.

• Loosen the upper vent plug and the lower drain plug.

• Drain the oil from the support and let it drain.

• Replace the lower plug and proceed with the filling as indicated in the previous section.

After some time of operation, the oil level in the reservoir should be checked. The reservoir should always contain oil, and the

oil should be replenished through the oil level maintainer.

7.3.2 Oil level

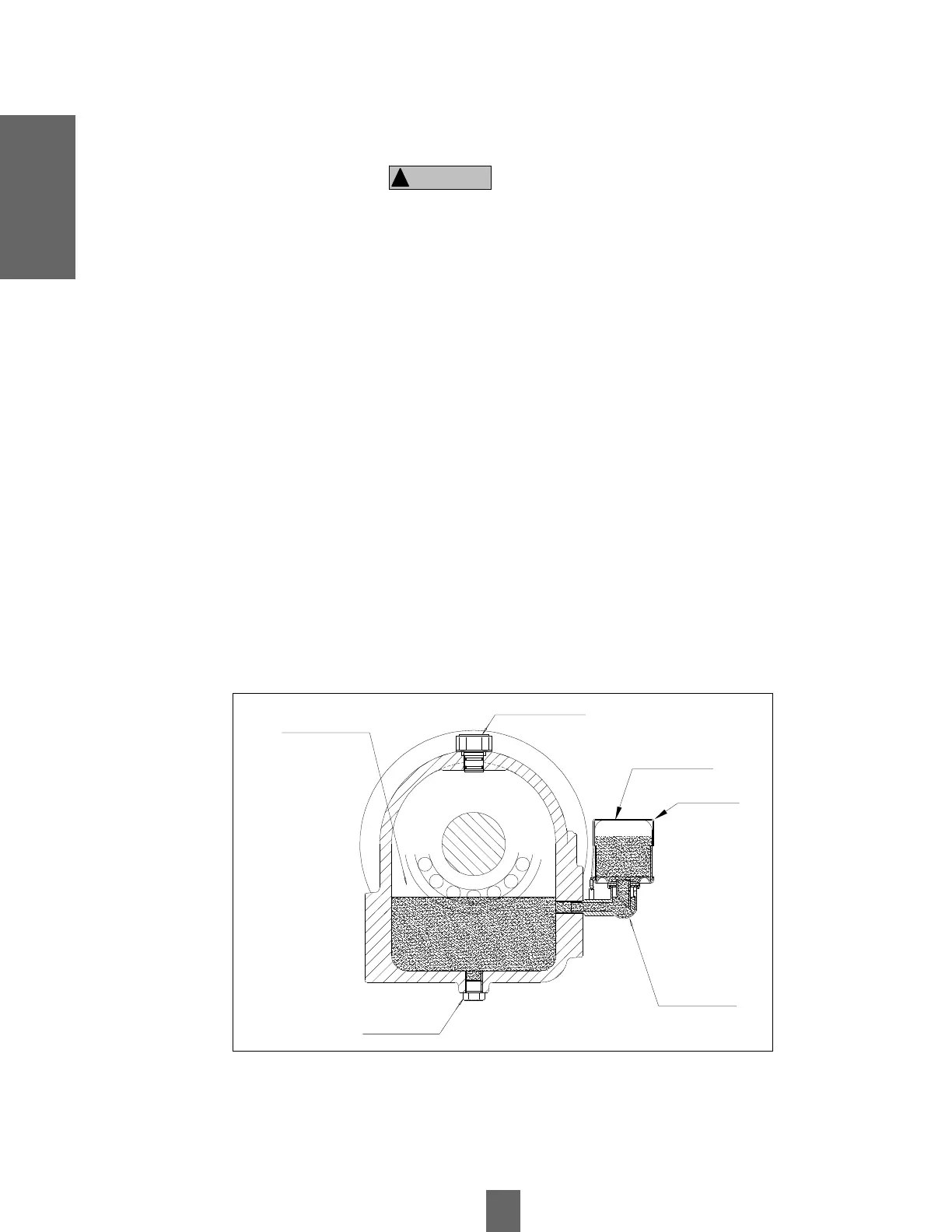

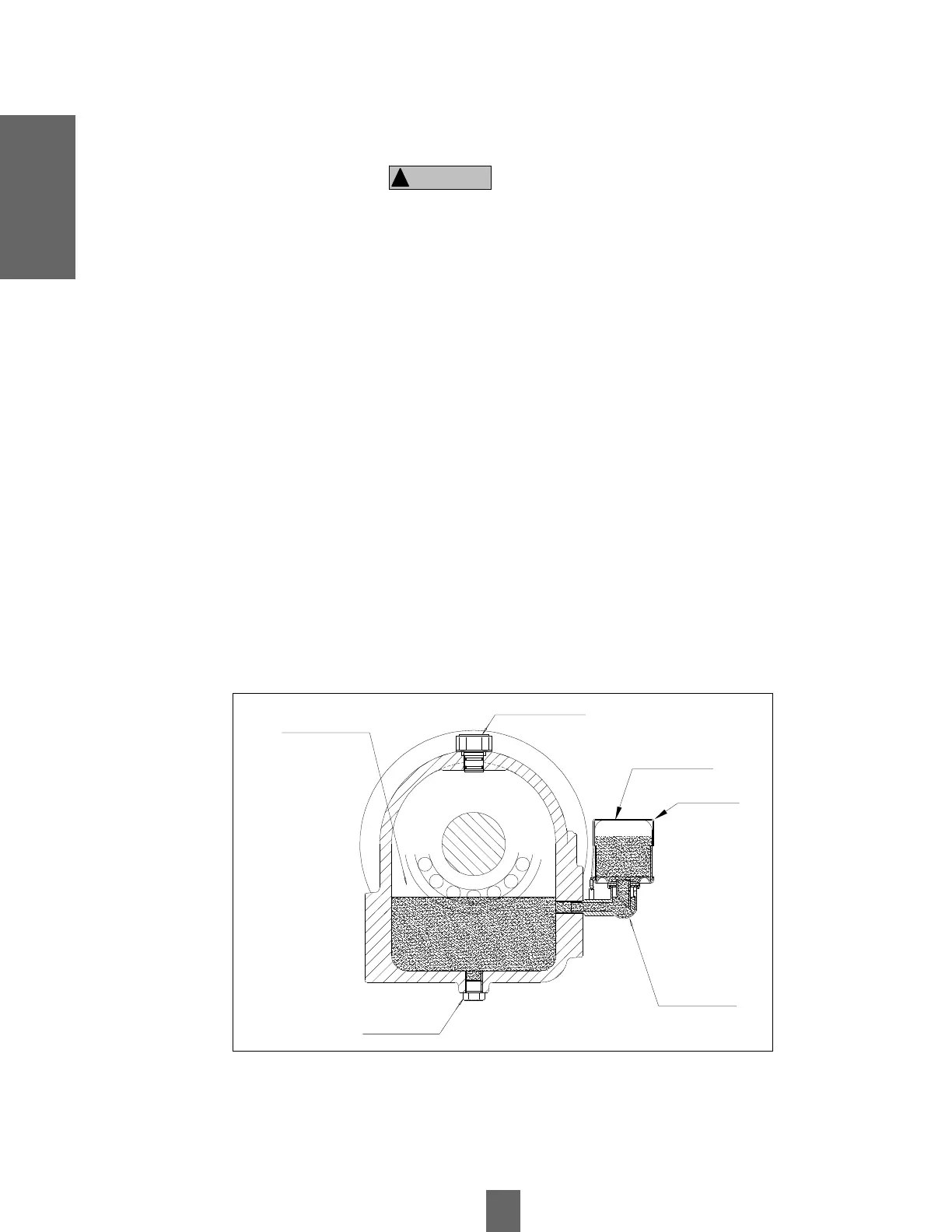

The oil level inside the bearing body, for a correct lubrication and cooling of the bearings, corresponds to the level that covers

half of the lower ball of the bearings, see figure 16. The oil level maintainer system is designed so that with a correct filling

procedure, this optimum level is automatically maintained for pump operation.

As the system is designed to maintain the optimum oil level, any excess oil will tend to overflow out of the bearing body, for

example, through the labyrinth seals, so it is essential to be very careful in the filling procedure and maintenance of the oil level.

Too much oil also means overheating of the bearings.

! WARNING

DRAIN PLUG

OIL LEVEL FOR

CORRECT

OPERATION

CONNECTION

ELBOW

VENT PLUG

WORKING POSITION

RESERVE TANK

Figure 16

Loading...

Loading...