17

Installation

In

stallation

5.6 Expansion Joint

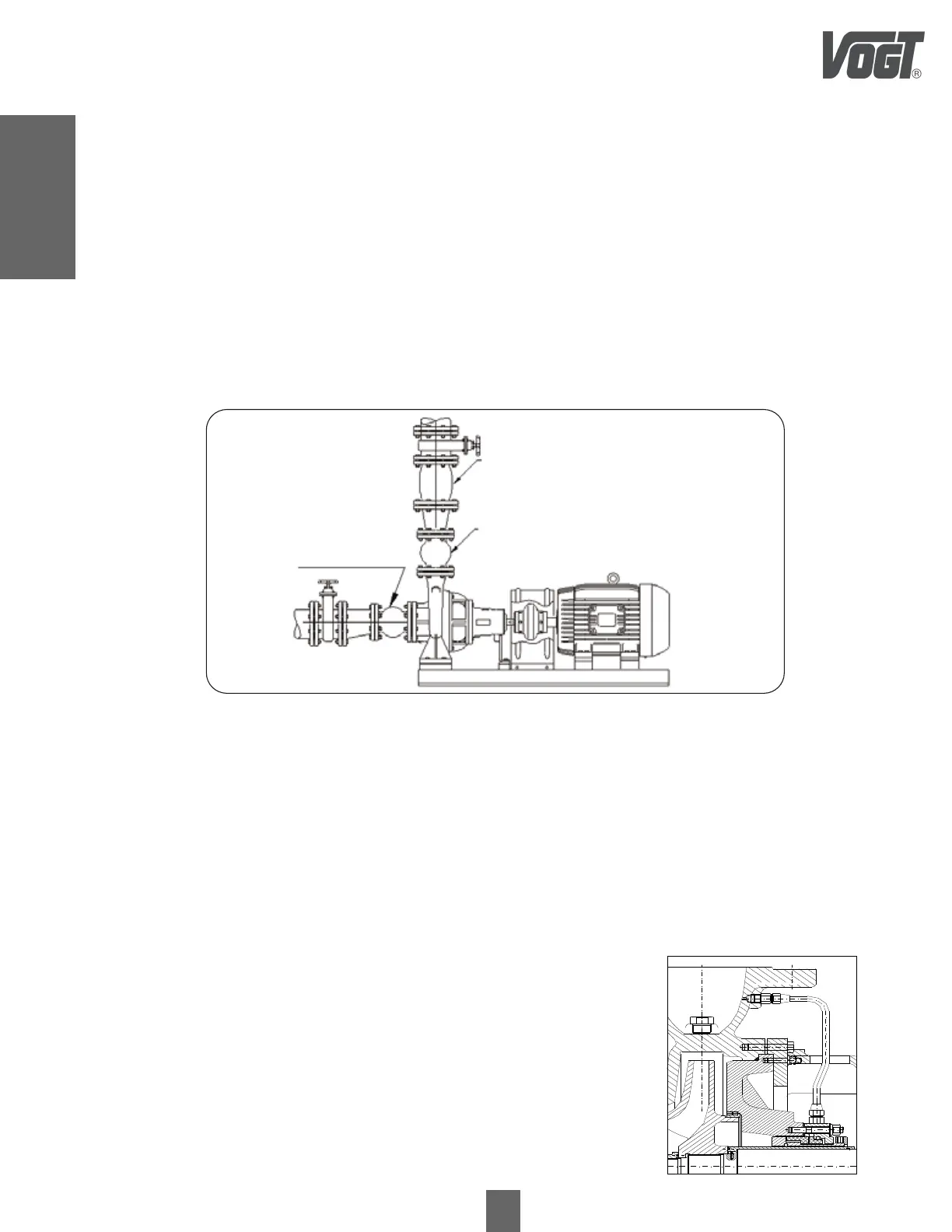

Dimensional changes in piping and equipment, caused by variations in the working temperature of the piping system and the

pump, either by the temperature of the pumped fluid or by exposure to changing environmental conditions, result in large

magnitude stresses and forces that are transmitted to the pumping equipment and can damage it. That is why VOGT S.A.,

recommends the use of expansion joints as part of the piping system that connects to the pump, when conditions warrant it, see

figure 12.

Even though the absorption of axial movements, caused by temperature changes, is the main work performed by the expansion

joints, they also act as vibration isolators reducing the propagation of vibrations, produced by the operation of the equipment,

through the piping system and also act as compensators of lateral, angular and torsional movements.

CHECK VALVE

EXPANSION JOINT

EXPANSION JOINT

Figure 12

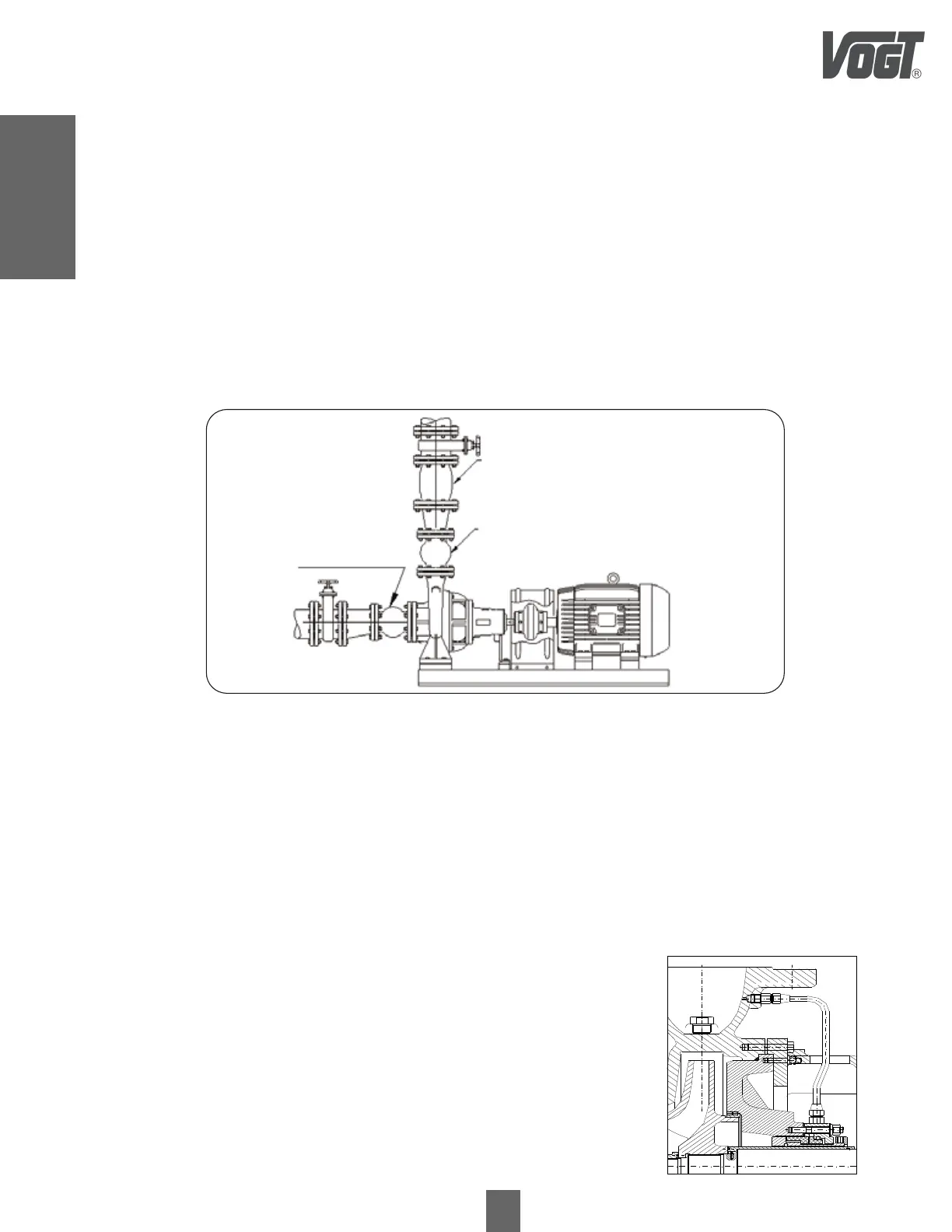

Circulation is carried out by injecting the pumped fluid from the pump discharge

through an external pipe, see figure 13. This pipe is incorporated in the pump and

should only be checked to ensure that it has not been damaged during transport,

assembly or operation.

5.7 Auxiliary Connections

These pumps will have, as standard, one of the following connections:

• API 11 cooling and circulation plan for packing case.

• API 11 cooling and circulation plan for DIN single seal and DIN balanced single seal case.

• API 11-61 cooling and circulation plan for the case of DIN single seal and DIN balanced single seal.

For other types of API plans, a diagram is included in the attached sheets. When there are auxiliary pipes, it should be noted

that these are designed to support exclusively the internal stresses due to the pressure of the fluid they circulate, so it is

forbidden to subject them to external supplementary stresses (e.g. support, etc.).

5.7.1 API-11 Refrigeration and Circulation Plan

Figure 13

Loading...

Loading...