86

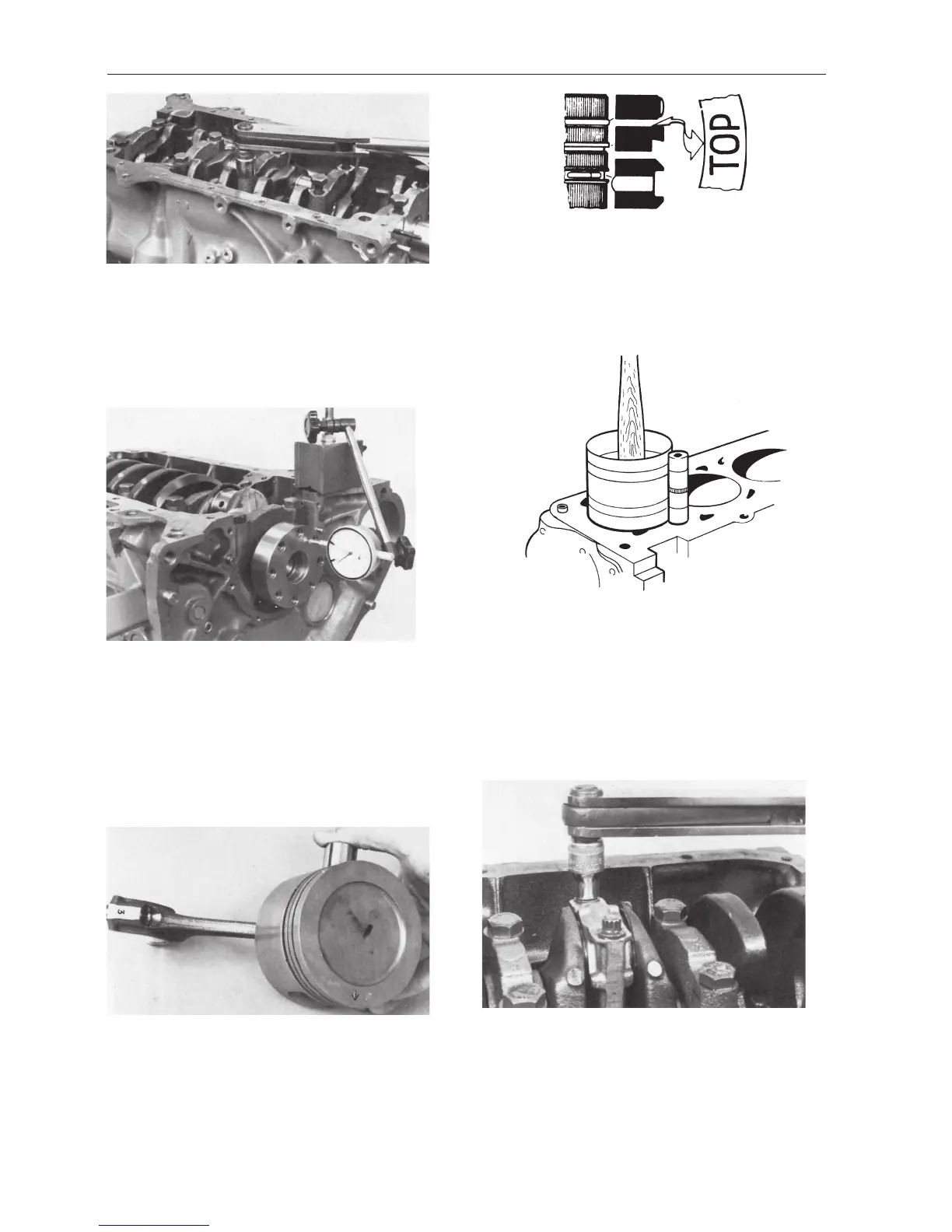

259. Install the main bearing caps.

NOTE! The main bearing caps are numbered 1 to 5,

counted from the timing gear end. Oil the threads of

the screws. Tighten with a torque wrench. Tightening

torque: 110 Nm (11.0 kpm/79.5 ft.lbs).

260. Check the axial clearance, which should be

0.080–0.270 mm (0.00315–0.01063").

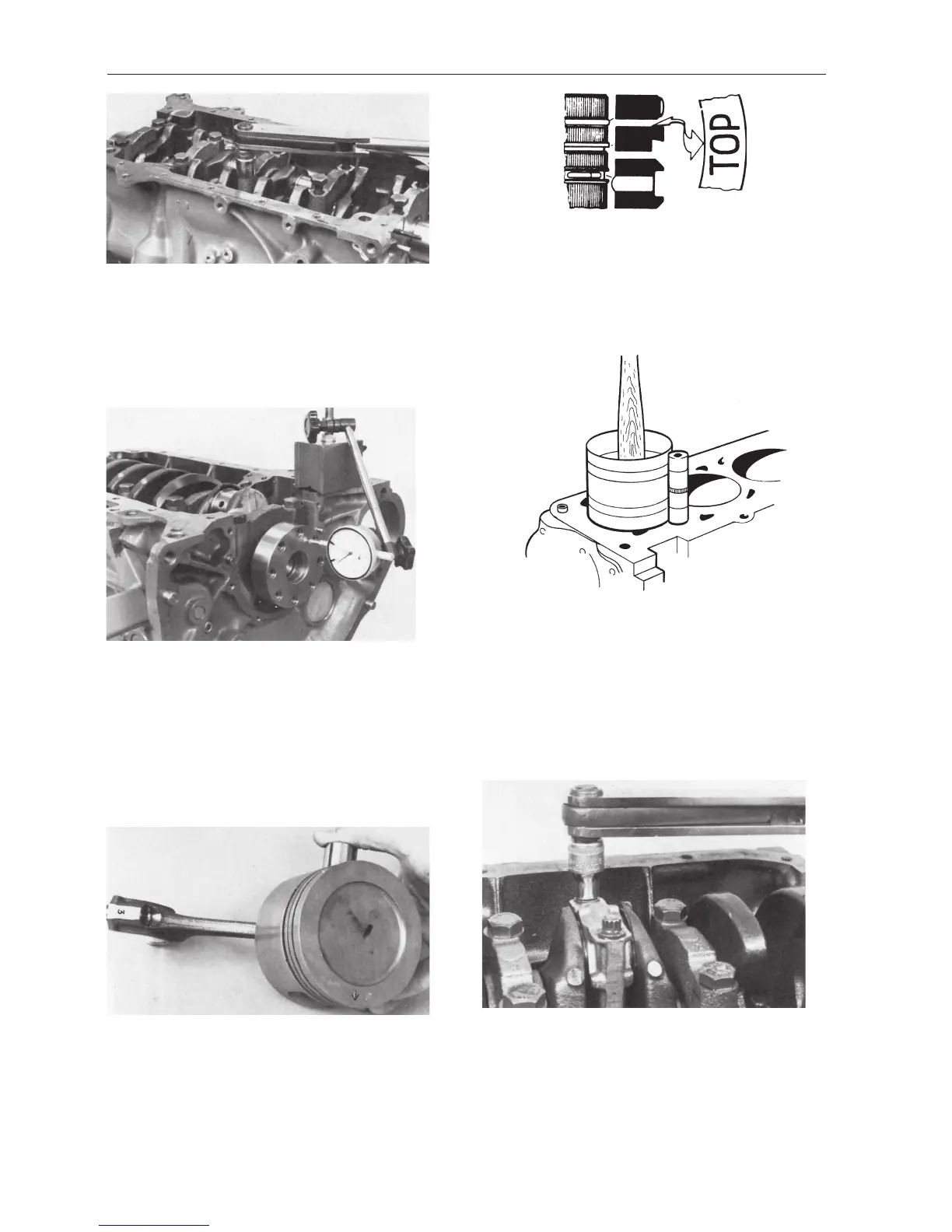

261. Assemble the pistons and connecting rods so

that the marking on the piston points forwards when

the number marking on the connecting rod is turned

towards the starboard side of the engine (the oil filter

side). Install the locking rings in the piston pins.

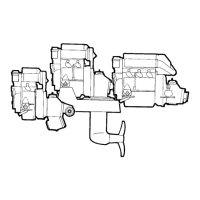

262. Use piston ring pliers to install the piston rings.

Install the piston rings in accordance with the pic-

ture. The upper ring is chromium plated. The lower

compression ring is marked ‘Top’. Turn the piston

rings on the piston so that the gaps are 120° apart

from each other.

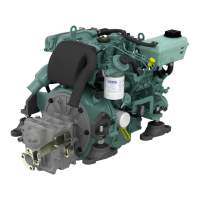

263. Install the bearing shells in the connecting rod

and in the caps. Oil the cylinder bore, piston and the

rod bearing. Check to make sure that the marking on

the piston is facing the timing gear cover when the

piston is installed in the cylinder. Use a piston ring

compressor to facilitate the installation.

NOTE! Turn the crankshaft so that the crank journal

for number 1 cylinder points straight downwards.

Push down the piston using a hammer handle.

264. Install the crank bearing caps so that the mark-

ing matches with the one on the connecting rod. Oil

the threads and use a torque wrench to tighten.

Tighten in 2 steps. Step 1: 20 Nm (2.0 kpm/15

ft.lbs). Step 2: Angle tighten 90°.

NOTE! Use new bolts should the length of the bolts

exceed 55.5 mm (2.185").

Loading...

Loading...