30

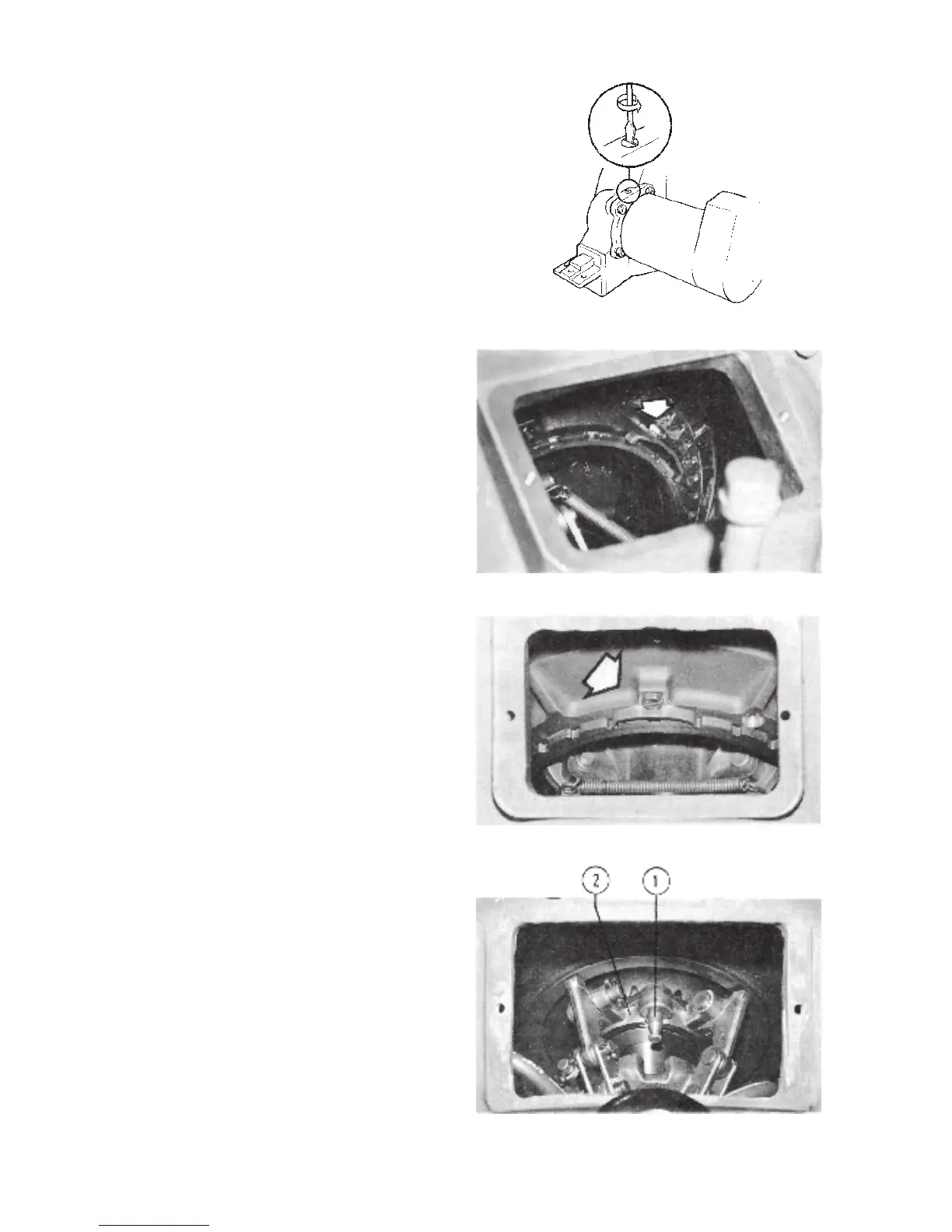

24. Starter motor, lubrication*

Lubricate the starter motor after every 600 hours of opera-

tion using Bosch oil 5944 290 000. Screw out the slotted

screw in the mounting flange against the flywheel housing

and fill the hole with oil, refit the screw and tighten it.

*Applies to starter motor type KG(R) which are provided with a

lubricating hole as shown in the figure.

25. Clutch -reduction gear,

checking and adjusting

Optional equipment TAMD70D

Check the function of the clutch after every 600 hours of

operation.

Check to see if the clutch slips, becomes warm or has a

tendency to disengage. If the clutch is equipped with reduc-

tion gear it should be checked with regard to abnormally

high noise level, temperature or leakage.

The Rockford/BW type clutches have a screw on locking

plate which retains the adjustment ring in position.

1. Remove the inspection cover. Set the lever to the

disengaged position and turn the clutch so that the

locking plate becomes accessible.

2. Loosen the locking plate and turn the adjustment ring

to the left so many notches that powerful force is

required to engage the lever.

3. Screw on the locking plate and inspection cover.

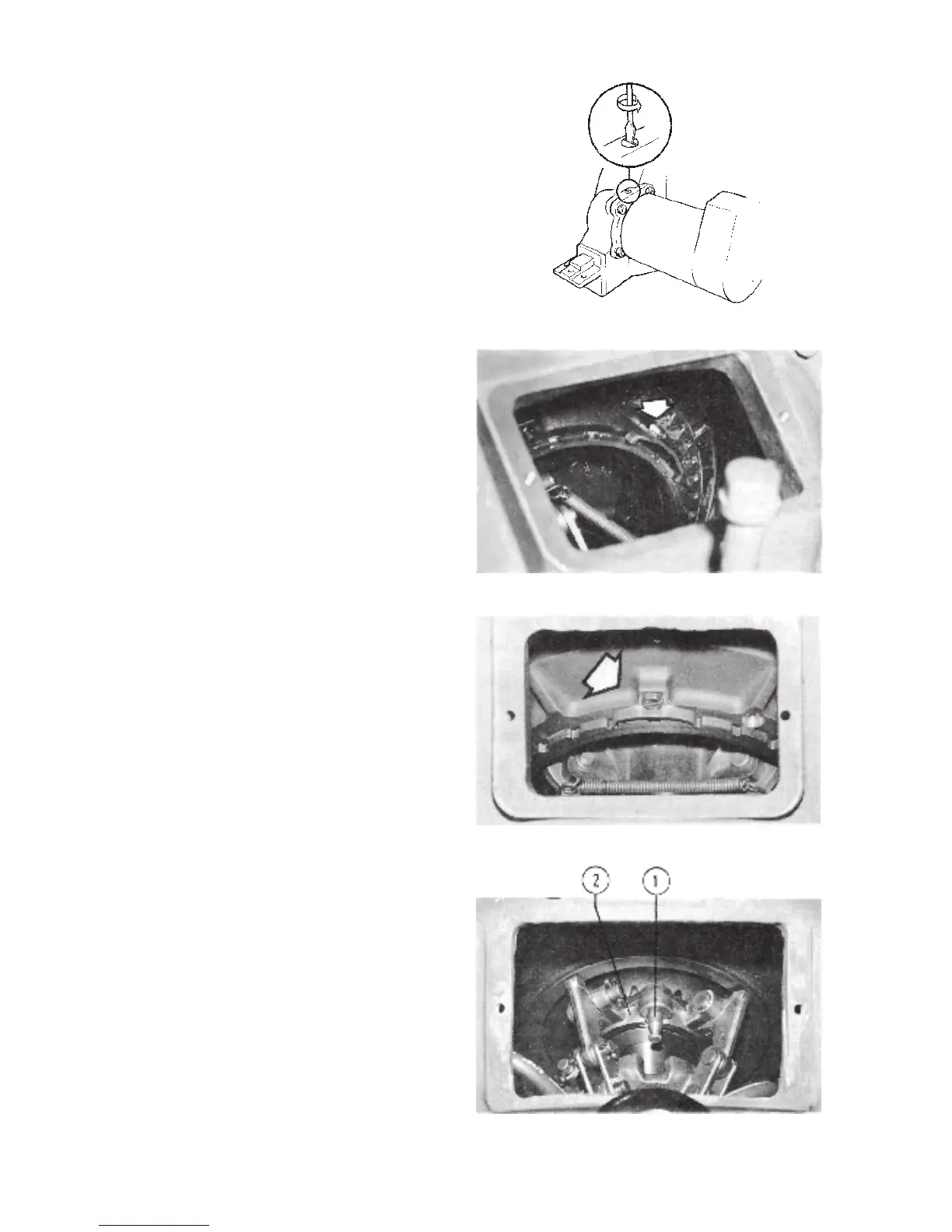

The Twin Disc type clutch is adjusted as follows:

1. Remove the inspection cover. Set the lever to the

disengaged position and turn the clutch so that the

locking pin (1) becomes accessible.

2. Pull out the locking pin and turn the adjustment ring (2)

so many notches to the right that a powerful force is

required to engage the lever.

3. Screw on the inspection cover.

Slotted screw for lubricating starter motor KG(R)

Rockford/BW type clutch, 203 mm (8")

Rockford/BW type clutch, 254 mm (10")

Twin Disc type clutch

Loading...

Loading...