10 Maintenance

26 100_0201_mt_0004.fm

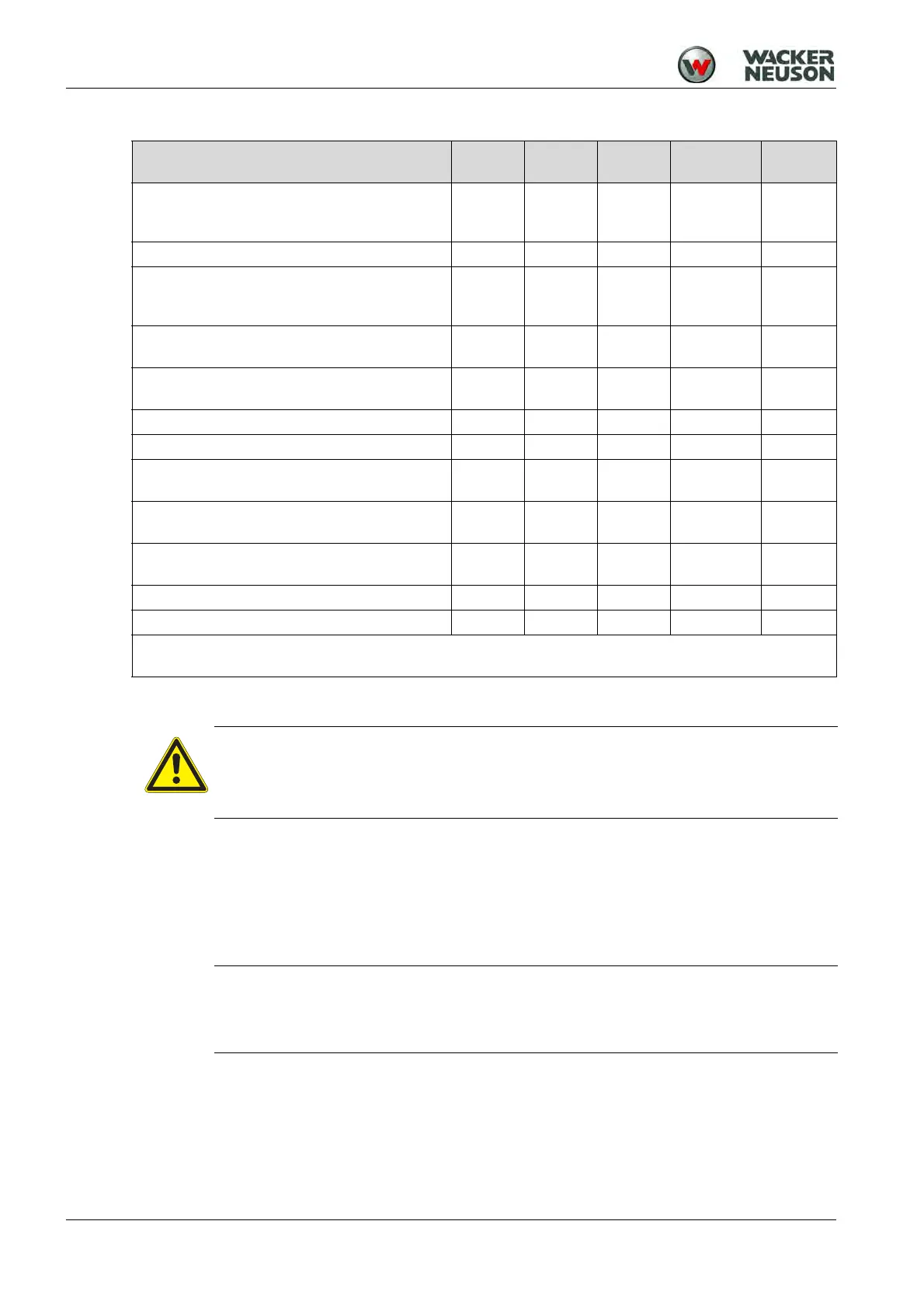

10.1 Maintenance table

10.2 Maintenance work

Carry out preparation work:

1. Place the machine on a level surface.

2. Decommissioning the machine.

3. Let the machine cool.

10.2.1 Clean the machine

1. After cleaning, check the cable, utility lines and hardware for loose connections, chafe marks and

other damage.

2. Immediately eliminate detected deficiencies.

Maintenance work daily weekly/

25 h

months/

100 h

3 months/

300 h

annually

Clean the machine

Visual check for completeness.

Visual inspection for damage.

Clean the air filter, replace if necessary.

Check the oil level, top off if necessary.

Percussion system.

Four-cycle engine.

Check the fuel lines and connections for cracks

and leaks. Replace if necessary.

Check screw connections of the ramming shoe.

Tighten if necessary.

Clean the cooling fins of the engine.

Clean the spark plug and check the gap.

Oil change.

Four-cycle engine.

Oil change.

Percussion system.

1

Check the central lifting point for wear, damage

or misuse.

Replace the spark plug.

Clean the fuel filter. Replace if necessary.

1

Change the oil after the first 50 hours of operation.

*

Have this work performed by the service department of your Wacker Neuson contact partner.

CAUTION

Health risk from fuel, lubricants and coolants.

Do not inhale fuel, lubricants, coolants or vapors.

Avoid contact of skin or eyes with fuel, lubricants and coolants.

NOTICE

Do not use high-pressure washers!

Penetrating water can damage the drive motor, electrical operator's controls or

components of the machine.

Loading...

Loading...