Do you have a question about the Xray XT8 and is the answer not in the manual?

| Scale | 1/8 |

|---|---|

| 4WD/2WD | 4WD |

| Width | 300 mm |

| Chassis Material | Aluminum |

| Shock Type | Oil-filled |

| Height | 180mm |

| Gear Type | Spur Gear |

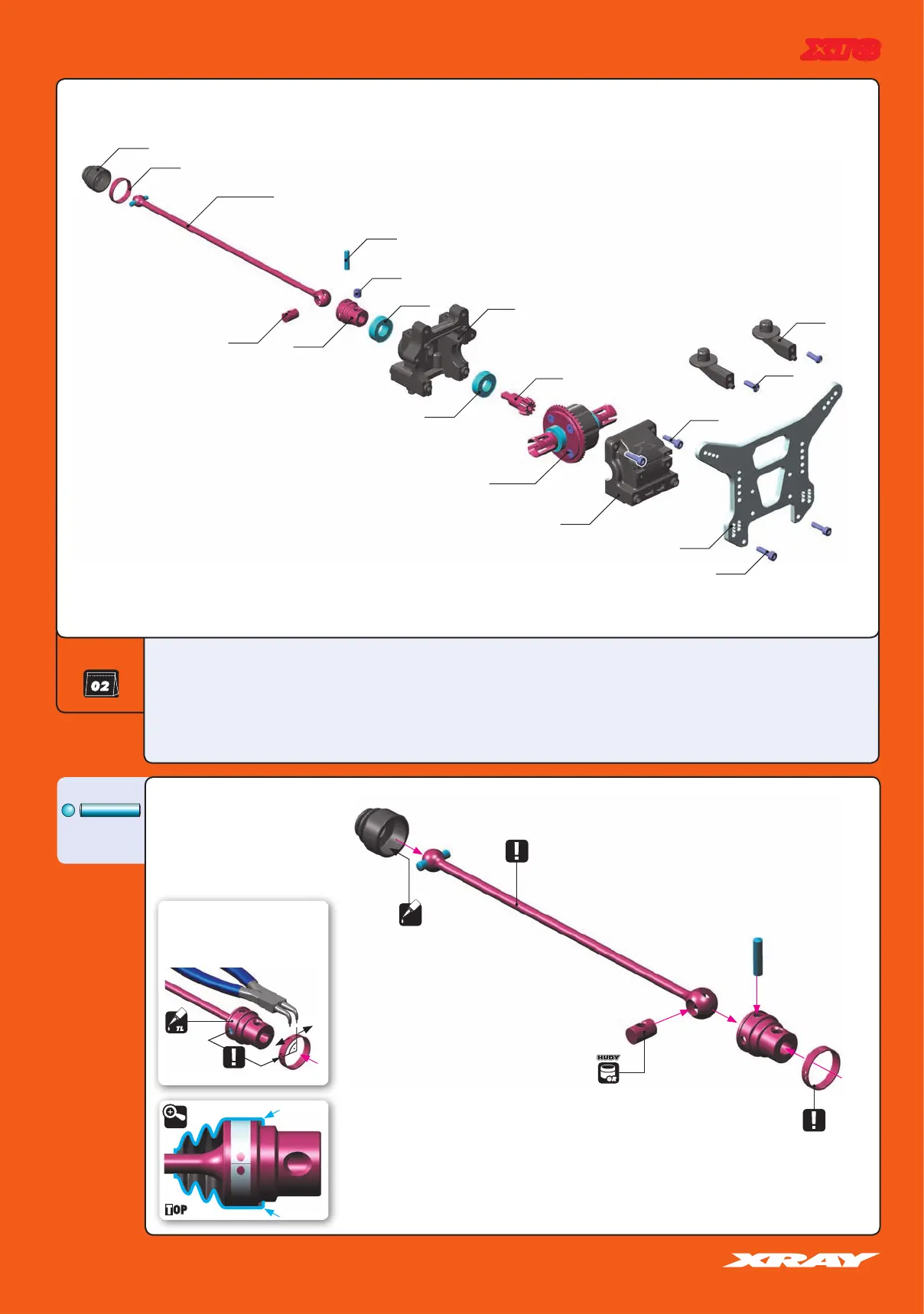

Adjusting differential side play for optimal gear mesh between diff and pinion gears.

Properly servicing drive shaft pins for maximum lifespan of drive shafts and diff outdrives.

Details on the large bevel gear options for front and rear differentials.

Instructions for filling differentials with silicone oil for initial settings and weight checks.

Details on the large spur gear options for the center differential.

Instructions for filling the center differential with silicone oil for initial settings.

Guidance on maintaining shock performance, refilling, bleeding, and replacing parts.

Checking suspension movement, drive shaft pins, and drivetrain components for wear.

Information on HUDY Spring Steel™ material properties and durability.

Procedures for cleaning and lubricating bearings for smooth operation and long life.

Recommendations for cleaning and lubricating clutch bearings to prolong their lifespan.