YORK INTERNATIONAL 49

FORM 160.49-O1

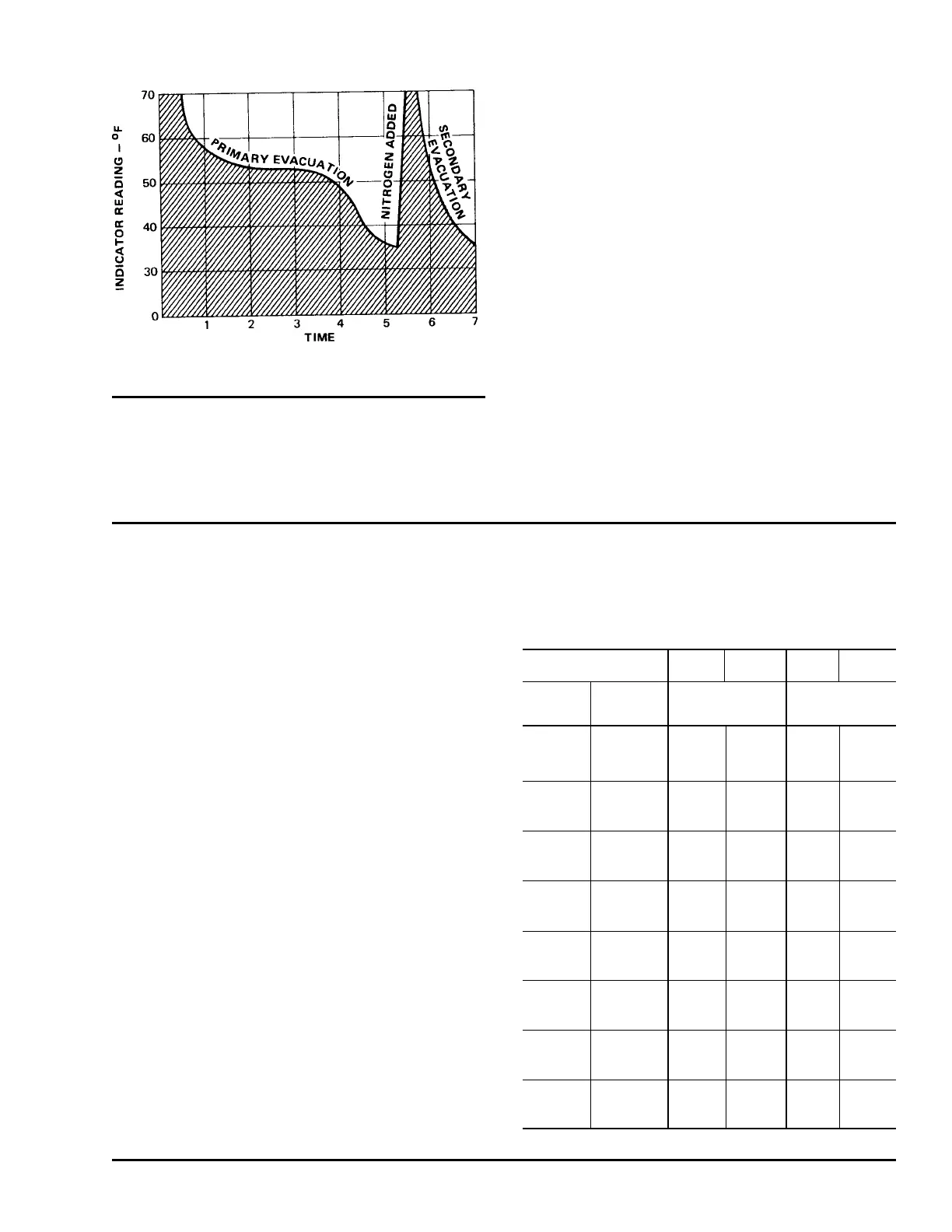

medium for carrying this residual moisture to the

vacuum pump, nitrogen should be introduced into the

system to bring it to atmospheric pressure and the

indicator temperature will return to approximately am-

FIG. 22 – SATURATION CURVE

bient temperature. Close off the system again, and start

the second evacuation.

The relatively small amount of moisture left will be car-

ried out through the vacuum pump and the tempera-

ture or pressure shown by the indicator should drop

uniformly until it reaches a temperature of 35°F (1.7°C)

or a pressure of 5 mm Hg.

When the vacuum indicator registers this temperature

or pressure, it is a positive sign that the system is

evacuated and dehydrated to the recommended limit.

If this level cannot be reached, it is evident that there

is a leak somewhere in the system. Any leaks must be

corrected before the indicator can be pulled down to

35°F (1.7°C) or 5 mm Hg. in the primary evacuation.

During the primary pulldown, keep a careful watch on

the wet bulb indicator temperature, and do not let it fall

below 35°F (1.7°C). If the temperature is allowed to fall

to 32°F (0°C), the water in the test tube will freeze,

and the result will be a faulty temperature reading.

LD01084

REFRIGERANT CHARGING

To avoid the possibility if freezing liquid within the cooler

tubes when charging an evacuated system, only re-

frigerant vapor from the top of the drum or cylinder

must be admitted to the system pressure until the sys-

tem pressure is raised above the point corresponding

to the freezing point of the cooler liquid. For water, the

pressure corresponding to the freezing point is 57.5

PSIG (396.5 kPa) for R-22 or 8.54 PSIG (58.9 kPa) for

R-134a (at sea level).

While charging, every precaution must be taken to pre-

vent moisture laden air from entering the system. Make

up a suitable charging connection from new copper

tubing to fit between the system charging valve and

the fitting on the charging drum. This connection should

be as short as possible but long enough to permit suf-

ficient flexibility for changing drums. The charging con-

nection should be purged each time a full container of

refrigerant is connected and changing containers should

be done as quickly as possible to minimize the loss of

refrigerant.

Refrigerant may be furnished in drums containing ei-

ther 30, 50, 125 or 1750 lbs. (13.6, 22.7, 56.7 or 793.8

kg) of refrigerant. These drums are not returnable and

they should be stored for future use if it should ever

become necessary to remove refrigeration from the

system.

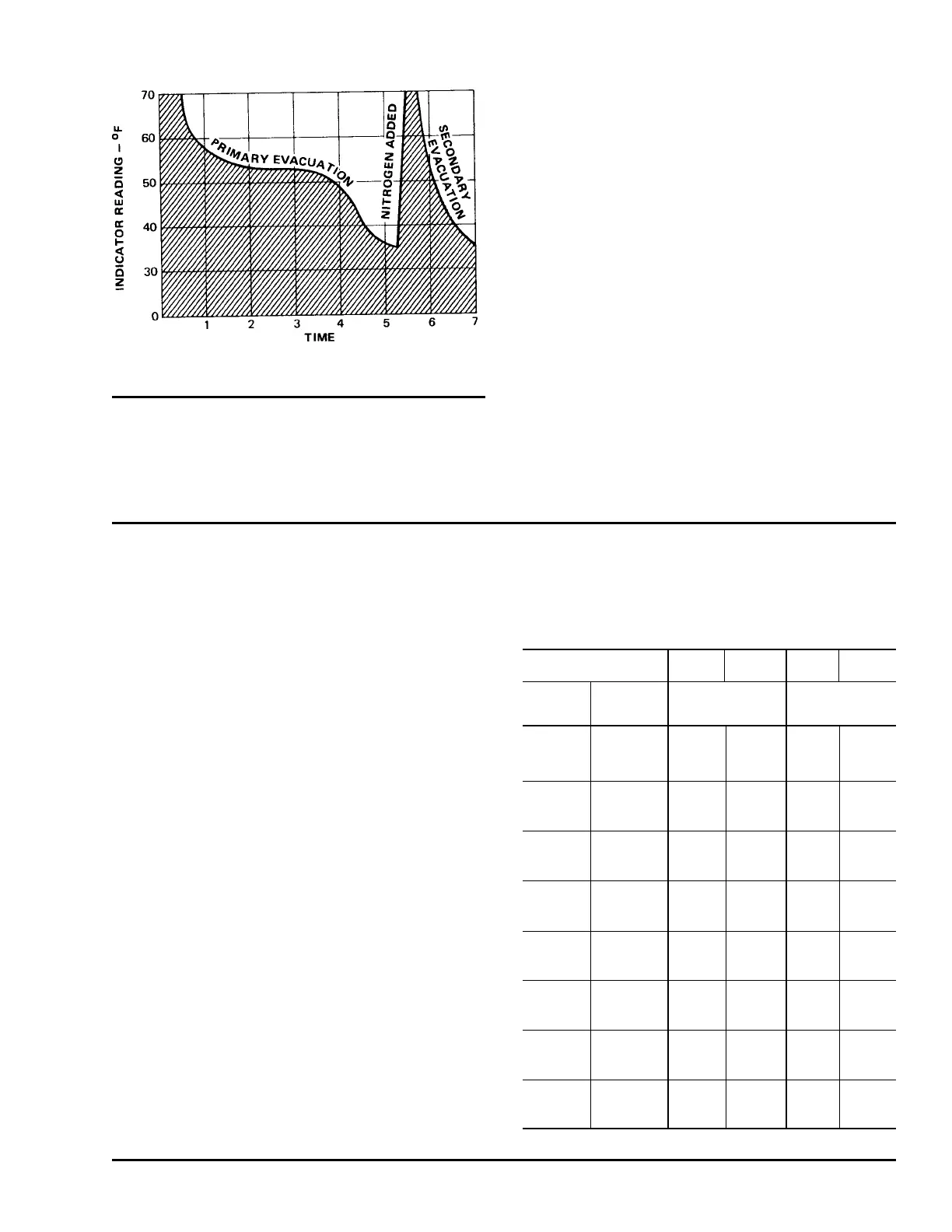

TABLE 4 – REFRIGERANT CHARGE

SHELL CODES R-22 R-134a R-22 R-134a

Cooler

Con-

denser

(Lbs.) (Kg.)

L L 1350 1340 612 608

L M 1475 1465 669 665

M L 1525 1525 691 691

M M 1625 1625 737 737

M N 1850 1840 839 835

N M 1900 1905 861 864

N N 2125 2125 964 964

N P 2125 2125 964 964

P N 2175 2185 987 991

P P 2175 2185 987 991

P Q 2500 2530 1134 1147

Q P 2550 2560 1157 1161

Q Q 2925 2905 1327 1318

Q R 3250 3250 1474 1465

R Q 3500 3500 1588 1588

R R 3850 3840 1746 1742

Loading...

Loading...