5803641-JIM-B-0620

40 Johnson Controls Ducted Systems

Air Balance

Start the supply air blower motor. Adjust the resistances in both

the supply and the return air duct systems to balance the air

distribution throughout the conditioned space. The job

specifications may require that this balancing be done by

someone other than the equipment installer.

Checking Air Quantity

Method One

1. Remove the dot plugs from the duct panel (for location of

the dot plugs see Figures 12 and 13).

2. Insert eight-inches of 1/4 inch metal tubing into the airflow

on both sides of the indoor coil.

NOTE: The tubes must be inserted and held in a position

perpendicular to the air flow so that velocity pressure

will not affect the static pressure readings.

3. Use an Inclined Manometer or Magnehelic to determine

the pressure drop across a dry evaporator coil. Since the

moisture on an evaporator coil can vary greatly, measuring

the pressure drop across a wet coil under field conditions

could be inaccurate. To assure a dry coil, the compressors

should be de-activated while the test is being run.

NOTE: De-energize the compressors before taking any test

measurements to assure a dry evaporator coil.

4. The CFM through the unit can be determined from the

pressure drop indicated by the manometer by referring to

Figure 28. In order to obtain an accurate measurement, be

certain that the air filters are clean.

5. To adjust Measured CFM to Required CFM, see.

6. After readings have been obtained, remove the tubes and

replace the dot plugs.

7. Tighten blower pulley and motor sheave set screws after

any adjustments. Re-check set screws after 10-12 hrs. run

time is recommended.

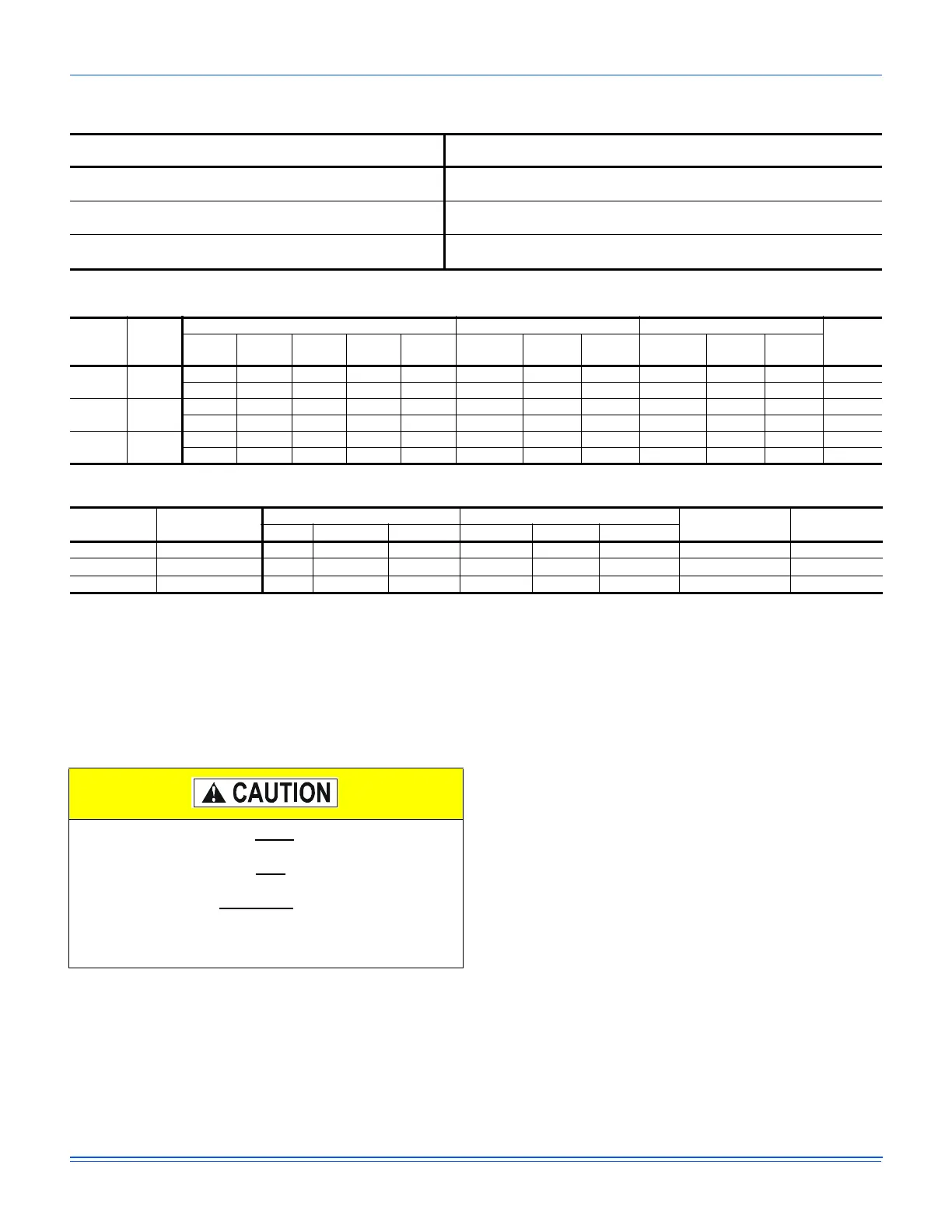

Table 19: RPM Selection

Size

(Tons)

Model HP

Max

BHP

Motor

Sheave

Blower

Sheave

6 Turns

Open

5 Turns

Open

4 Turns

Open

3 Turns

Open

2 Turns

Open

1 Turn

Open

Fully

Closed

JA3

(3)

ZJ

1.5 1.5 1VP34 AK69 N/A 531 584 637 690 743 796

1.5 1.5 1VL44 AK69 N/A 796 849 902 955 1008 1062

JA4

(4)

ZJ

1.5 1.5 1VP34 AK56 N/A 663 730 796 863 929 995

1.5 1.5 1VL44 AK56 N/A 995 1062 1128 1194 1261 1327

JA5

(5)

ZJ

1.5 1.5 1VL40 AK61 N/A 787 847 908 968 1029 1089

2 2 1VP56 BK74 N/A 1035 1084 1134 1183 1232 1281

Table 20: Indoor Blower Specifications

Size

(Tons)

Model

Motor Motor Sheave Blower Sheave

Belt

HP RPM Eff. SF Frame

Datum Dia.

(in.)

Bore (in.) Model

Datum Dia.

(in.)

Bore (in.) Model

JA3

(3)

ZJ

1-1/2 1725 0.8 1.15 56 2.0 - 3.0 7/8 1VM34 6.5 1 AK69 A47

1-1/2 1725 0.8 1.15 56 3.0 - 4.0 7/8 1VL44 6.5 1 AK69 A47

JA4

(4)

ZJ

1-1/2 1725 0.8 1.15 56 2.0 - 3.0 7/8 1VM34 5.2 1 AK56 A47

1-1/2 1725 0.8 1.15 56 3.0 - 4.0 7/8 1VL44 5.2 1 AK56 A47

JA5

(5)

ZJ

1-1/2 1725 0.8 1.15 56 2.6 - 3.6 7/8 1VL40 5.7 1 AK61 A47

2 1725 0.8 1.15 56 4.2 - 5.2 7/8 1VP56 7.0 1 BK74 A51

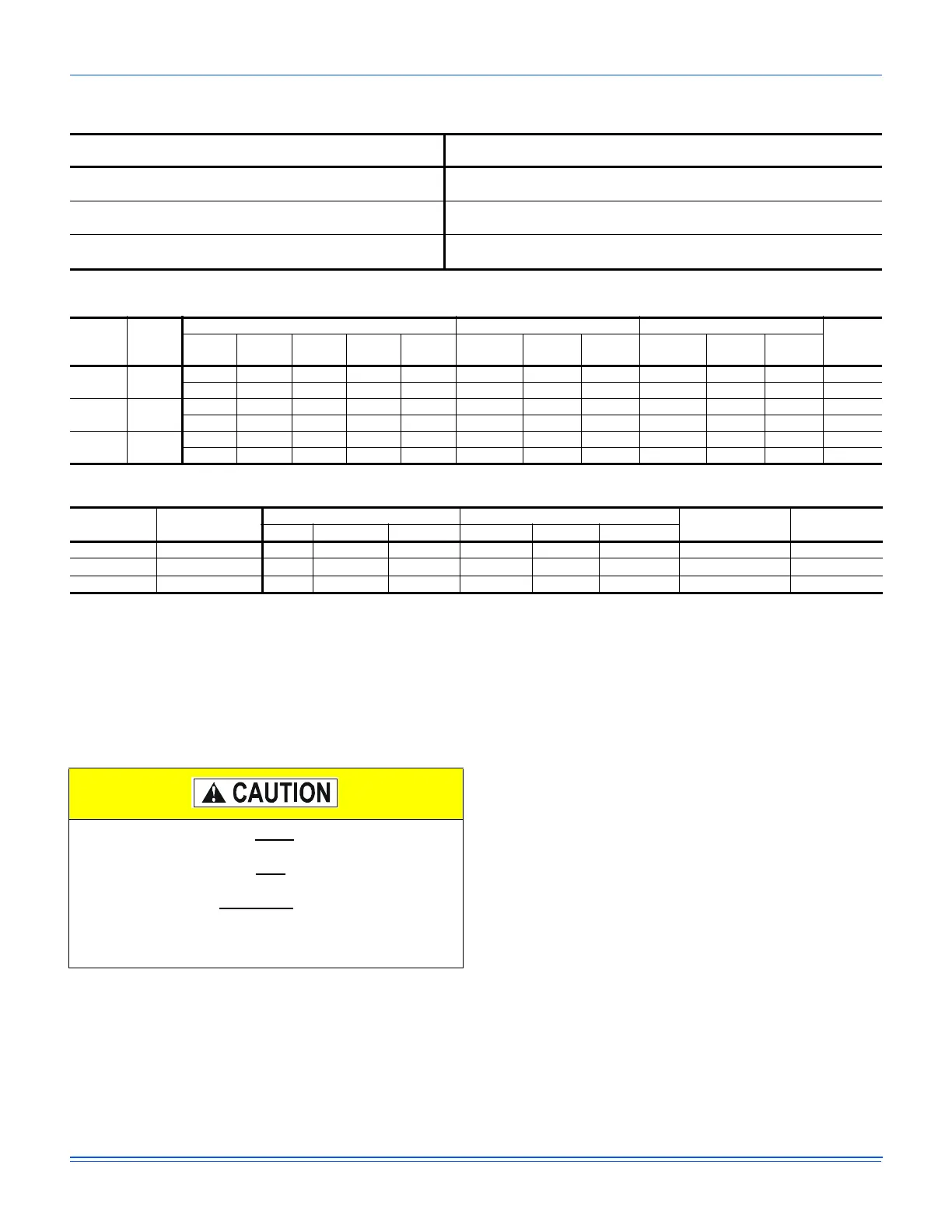

Table 21: Power Exhaust Specifications

Model Voltage

Motor Unit (Per Circuit)

Fuse Size

CFM @

0.1 ESP

HP RPM

1

1. Motors are multi-tapped and factory wired for high speed.

QTY LRA FLA MCA

2PE04704706 208/230-1-60 3/4 1075 1 24.9 5 6.3 10 4800

2PE04704746 460-1-60 3/4 1075 1 N/A 2.2 2.8 5 4800

2PE04704758 575-1-60 3/4 1050 1 N/A 1.5 1.9 4 4800

Belt drive blower systems MUST be adjusted to the

specific static and CFM requirements for the application.

The Belt drive blowers are NOT

set at the factory for any

specific static or CFM. Adjustments of the blower speed

and belt tension are REQUIRED

. Verify proper sheave

alignment; tighten blower pulley and motor sheave set

screws after these adjustments. Re-checking set screws

after 10-12 hrs. run time is recommended.

Loading...

Loading...