5803641-JIM-B-0620

Johnson Controls Ducted Systems 51

Adjustment Of Temperature Rise

The temperature rise (the difference of temperature between the

return air and the heated air from the furnace) must lie within the

range shown on the CSA rating plate and the data in Table 10.

After the temperature rise has been determined, the CFM can

be calculated as follows:

After about 20 minutes of operation, determine the furnace

temperature rise. Take readings of both the return air and the

heated air in the ducts (about 6 feet from the furnace) where

they will not be affected by radiant heat. Increase the blower

CFM to decrease the temperature rise; decrease the blower

CFM to increase the rise (See SUPPLY AIR DRIVE

ADJUSTMENT).

NOTE: Each gas heat exchanger size has a minimum

allowable CFM. Below this CFM, the limit will open.

Burners/Orifices Inspection/Servicing

Before checking or changing burners, pilot or orifices, CLOSE

MAIN MANUAL SHUT-OFF VALVE AND SHUT OFF ALL

POWER TO THE UNIT.

1. Open the union fitting just upstream of the unit gas valve

and downstream from the main manual shut-off valve in

the gas supply line.

2. Remove the screws holding each end of the manifold to the

manifold supports.

3. Disconnect wiring to the gas valves and spark igniter(s).

Remove the manifold & gas valve assembly. Orifices can

now be inspected and/or replaced.

To service burners, complete step 4.

4. Remove the heat shield on top of the manifold supports.

Burners are now accessible for inspection and/or

replacement.

NOTE: Reverse the above procedure to replace the

assemblies.

Make sure that burners are level and seat at the rear of the gas

orifice.

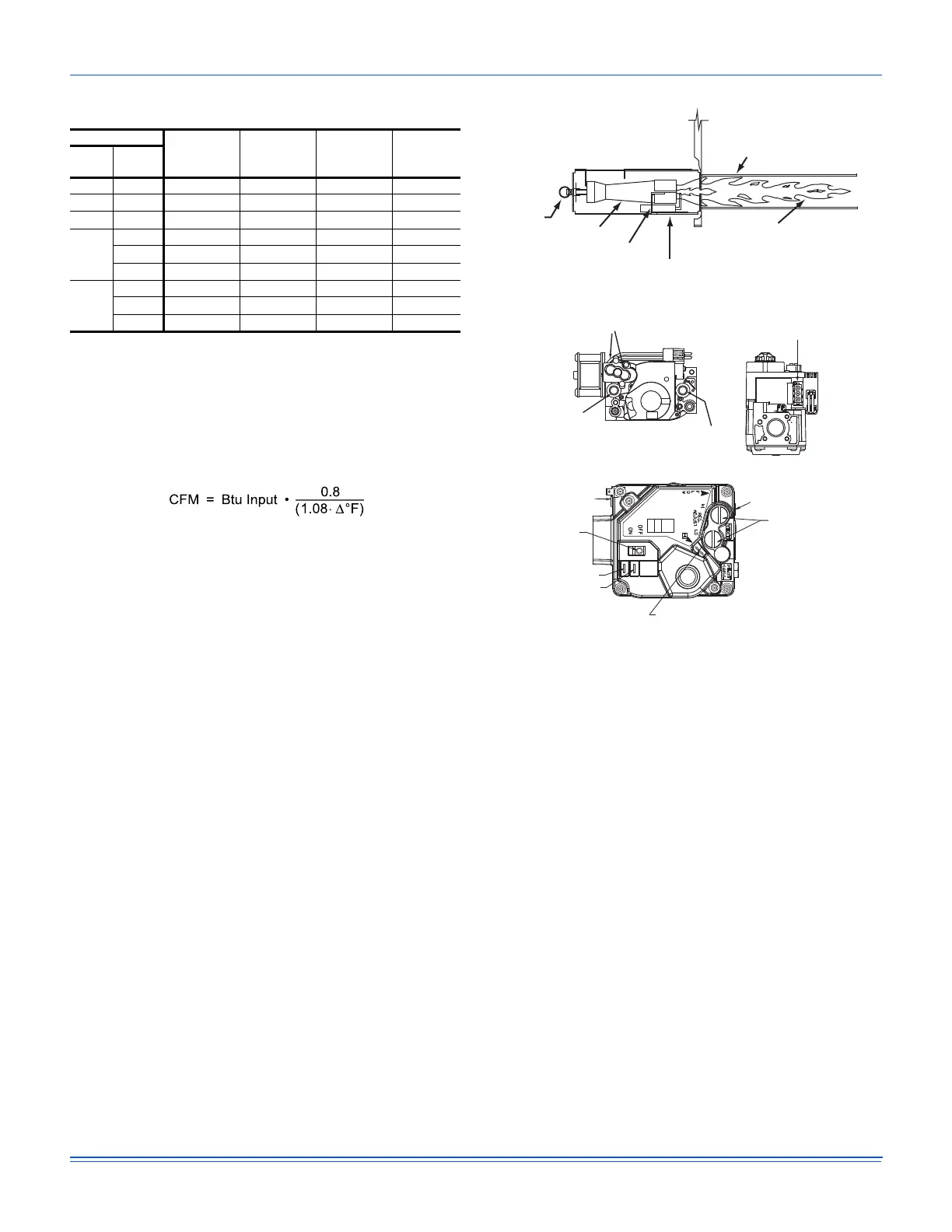

Figure 29: Typical Flame

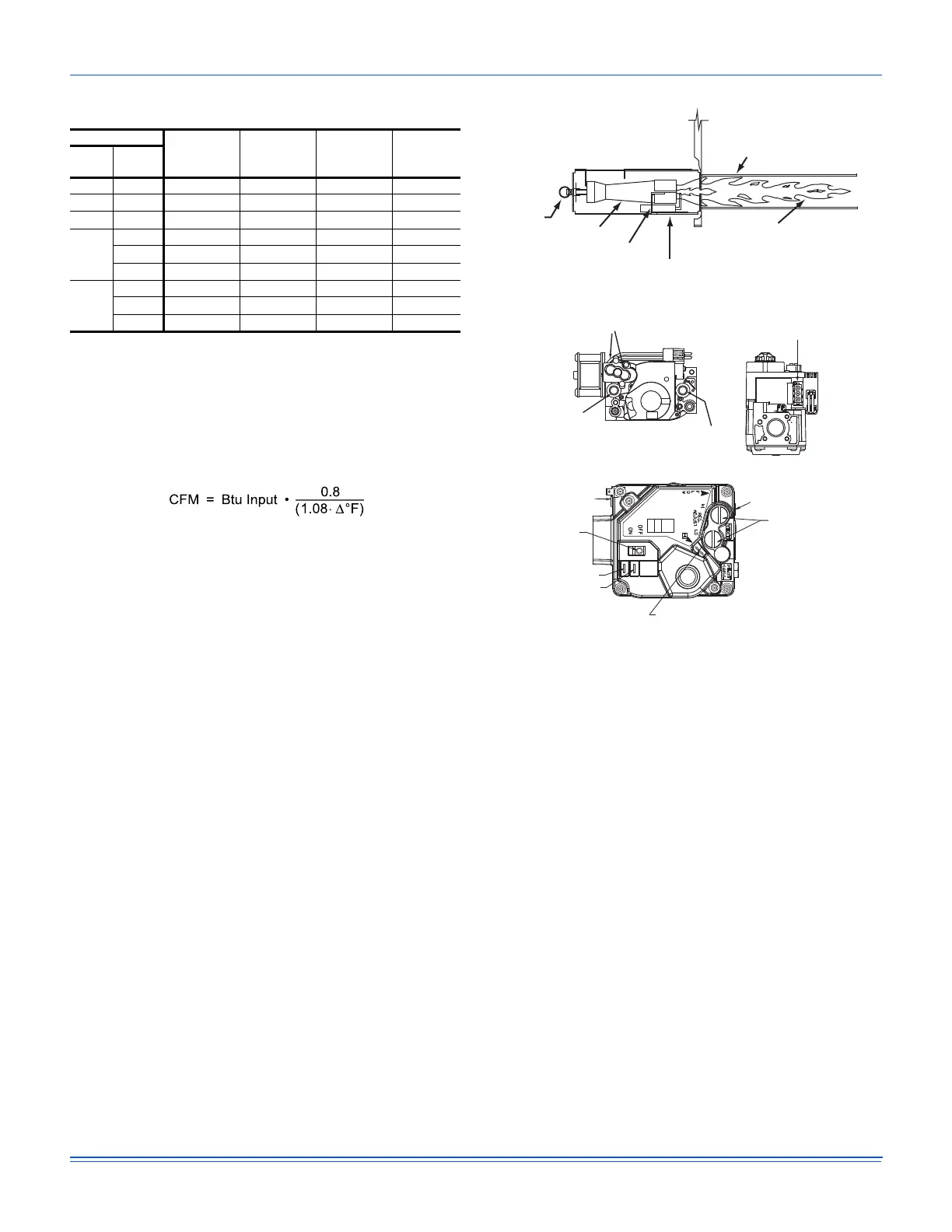

Figure 30: Typical Two Stage Gas Valve

Charging The Unit

All J**ZJ units use Thermal Expansion Devices. Charge the unit

to nameplate charge.

Control Board Navigation Components

The following components are needed to access the control

points in the Smart Equipment™ control. Installation and

operation guides are available from your equipment dealer or

distributor.

1. Local LCD on Unit Control Board.

2. Mobile Access Portal (MAP) Gateway (Portable).

• Source 1 P/N S1-JC-MAP1810-OP

3. MAP Gateway Quick Start Guide P/N 24-10737-16

4. MAP Gateway Instruction P/N 24-10737-8

For more information on the Smart Equipment™ unit control board

navigation, refer to the Smart Equipment™ Quick Start Guide.

NOTE: For more in-depth sequence of operation of the Smart

Equipment™ control, refer to the Smart Equipment™

Controls Sequence of Operation Overview LIT-

12011950.

Table 28: Gas Heat Stages

Unit

# of Burner

Tubes

1st Stage

Input (Mbh)

2nd Stage

Input

(Mbh)

Total

Input

(Mbh)

Size Opt.

JA3 N06 4 45 15 60

N08 4 56 24 80

N12 6 84 36 120

JA4

N06 4 45 15 60

N08 4 56 24 80

N12 6 84 36 120

JA5

N08 4 56 24 80

N12 6 84 36 120

N16 8 112 48 160

HEAT EXCHANGER TUBE

BURNER FLAME

(BLUE ONLY)

IGNITOR

BURNER BRACKET

BURNER

GAS

SUPPLY

PIPE

INLET

PRESSURE

TAP

HIGH & LOW GAS ADJUSTMENT

OUTLET

PRESSURE

TAP

HI

LO

ON

OFF

MATE-N-LOCK

CONNECTORS

MV

C

HI

REGULATOR COVER SCREWS

(REG. ADJ. BENEATH THESE

SCREWS)

TERMINAL – HI (2ND STAGE)

ON/OFF SWITCH

C

MP

OUTLET PRESSURE TAP

INLET PRESSURE TAP

OR

TERMINAL – MP (1ST STAGE)

TERMINAL – C (COMMON)

Loading...

Loading...