550.13-TG2Y (799)

4 Unitary Products Group

ules of both horizontal and vertical units. Since the casin

matches the dimensions and the finish of the basic unit, it

becomes an inte

ral part of the unit after installation. The coil

slides out of the casin

s for eas

installation and is pitched in

the casin

s to facilitate condensate draina

e. The coil has

copper tubes that have been mechanicall

expanded into alu-

minum fins. Both headers are located on the same end of the

coil. The coil is leak-tested at 325 psi

and dried before the

connections are capped for stora

e and shippin

.

BLOWER MOTORS Different HP motors are available for

each unit to meet almost an

air deliver

requirement. All

motors are UL approved, have permanentl

lubricated ball

bearin

s and are field-mounted within the insulated cabinet of

the units to minimize the transmission of sound to the sur-

roundin

space. All motors have inherent protection except

those available for the 50 ton unit. Motors for 50 ton units

require a starter and overload elements

DRIVE PACKAGES Different size pulle

s and belts are avail-

able for each unit to provide a blower RPM ran

e to meet

almost an

air deliver

requirement. Variable pitch motor pul-

le

s can be adjusted to provide the proper blower RPM. All

drive packa

es are rated at least 25% above the nominal HP

ratin

of the blower motor. Two-

roove pulle

s and two belts

are provided on ever

drive packa

e rated at 5 HP and

above.

STARTERS AND HEATER ELEMENTS (50 ton onl

) The

blower motors that are available for the 50 ton units do not

have inherent protection and require external motor overload

protection.

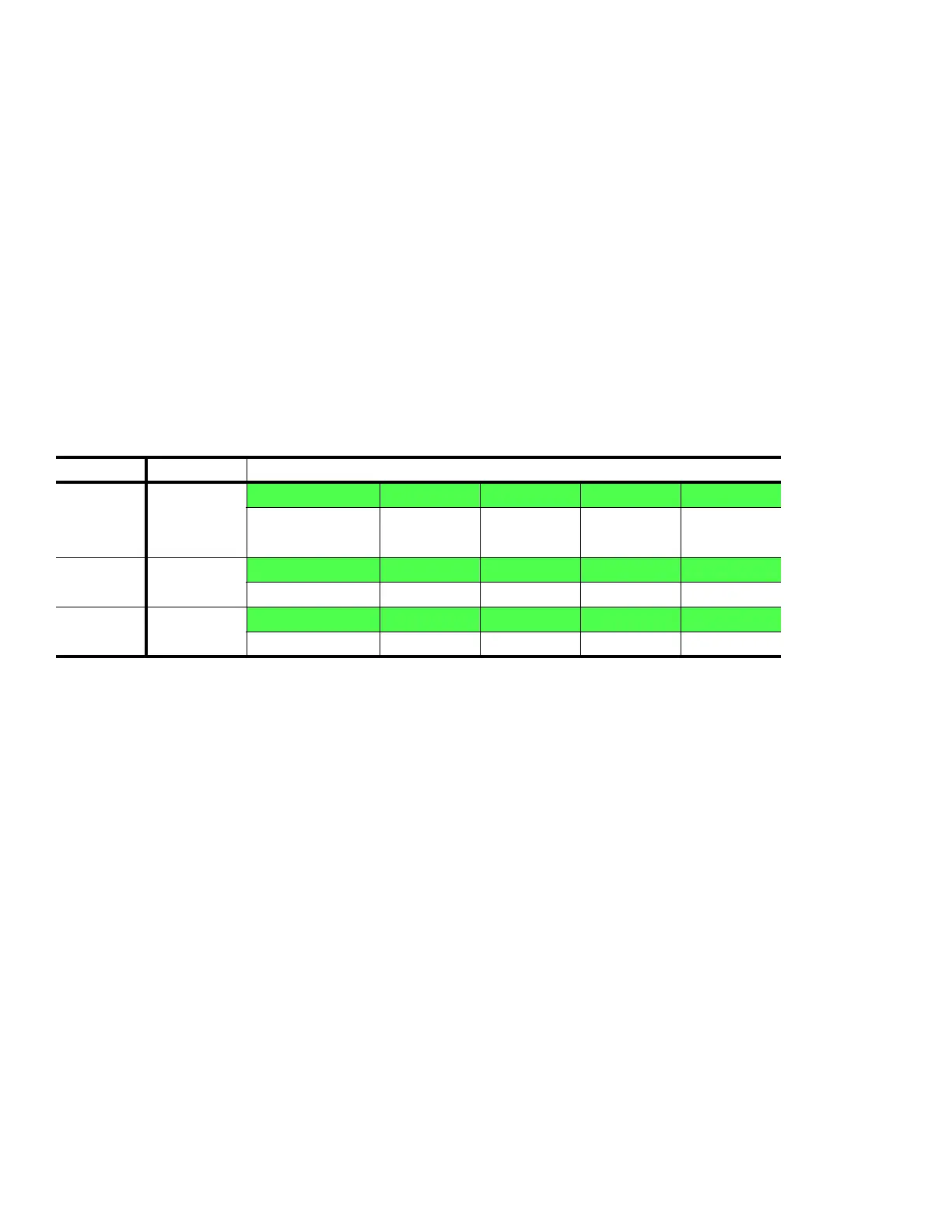

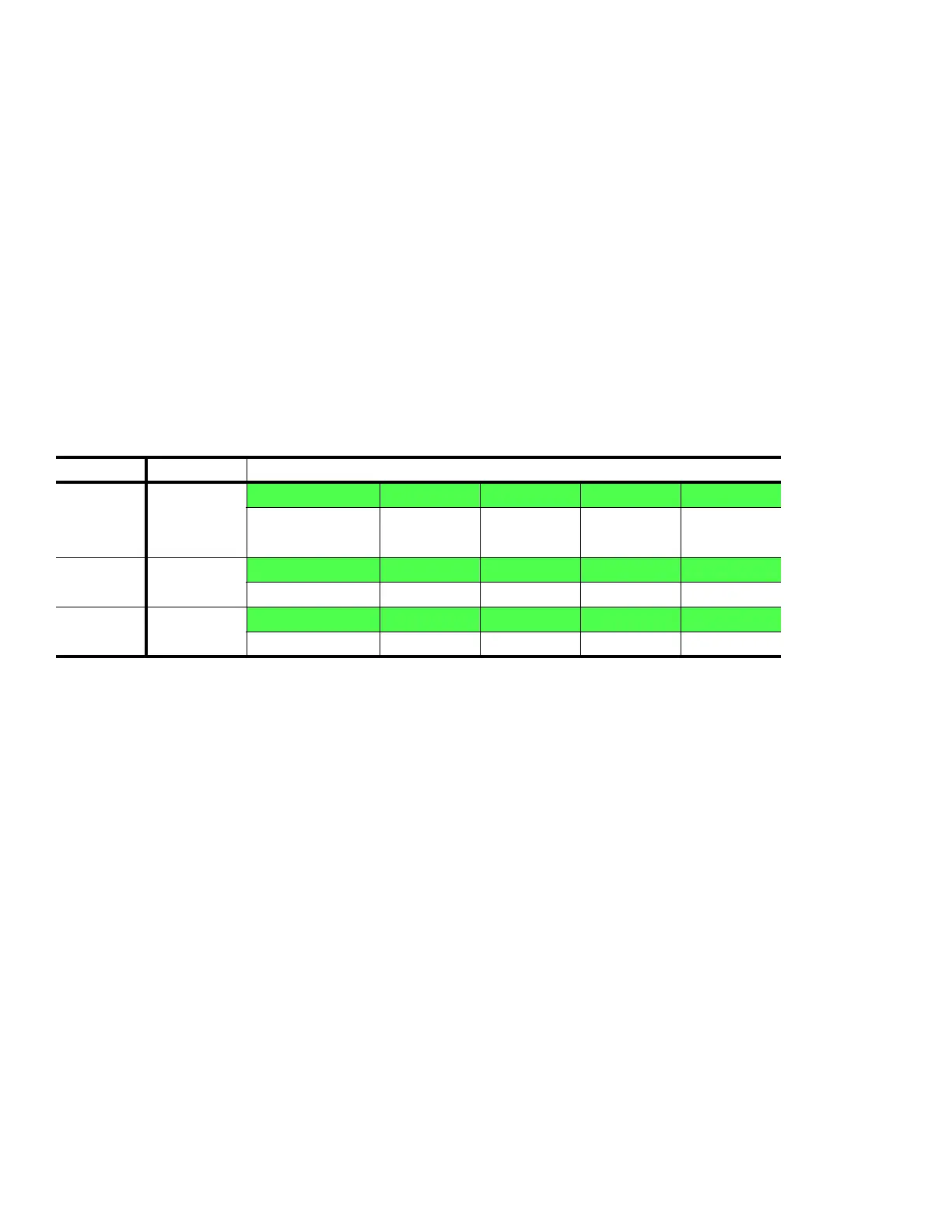

TABLE 1: STATIC RESISTANCES FOR UNIT ACCESSORIES

UNIT MODEL ACCESSORY CFM

LEU360

10,000 11,000 12,000 13,000 14,000

Hot Water Coil 0.08 0.09 0.10 0.12 0.14

Steam Coil 0.17 0.20 0.23 0.27 0.31

LEU480

12,800 14,400 16,000 17,600 19,200

Hot Water Coil 0.11 0.13 0.15 0.17 0.20

LEU600

16,000 18,000 20,000 22,000 24,000

Hot Water Coil 0.15 0.18 0.21 0.24 0.28

Loading...

Loading...