YORK INTERNATIONAL 5

FORM 160.49-O2

7619A(D)

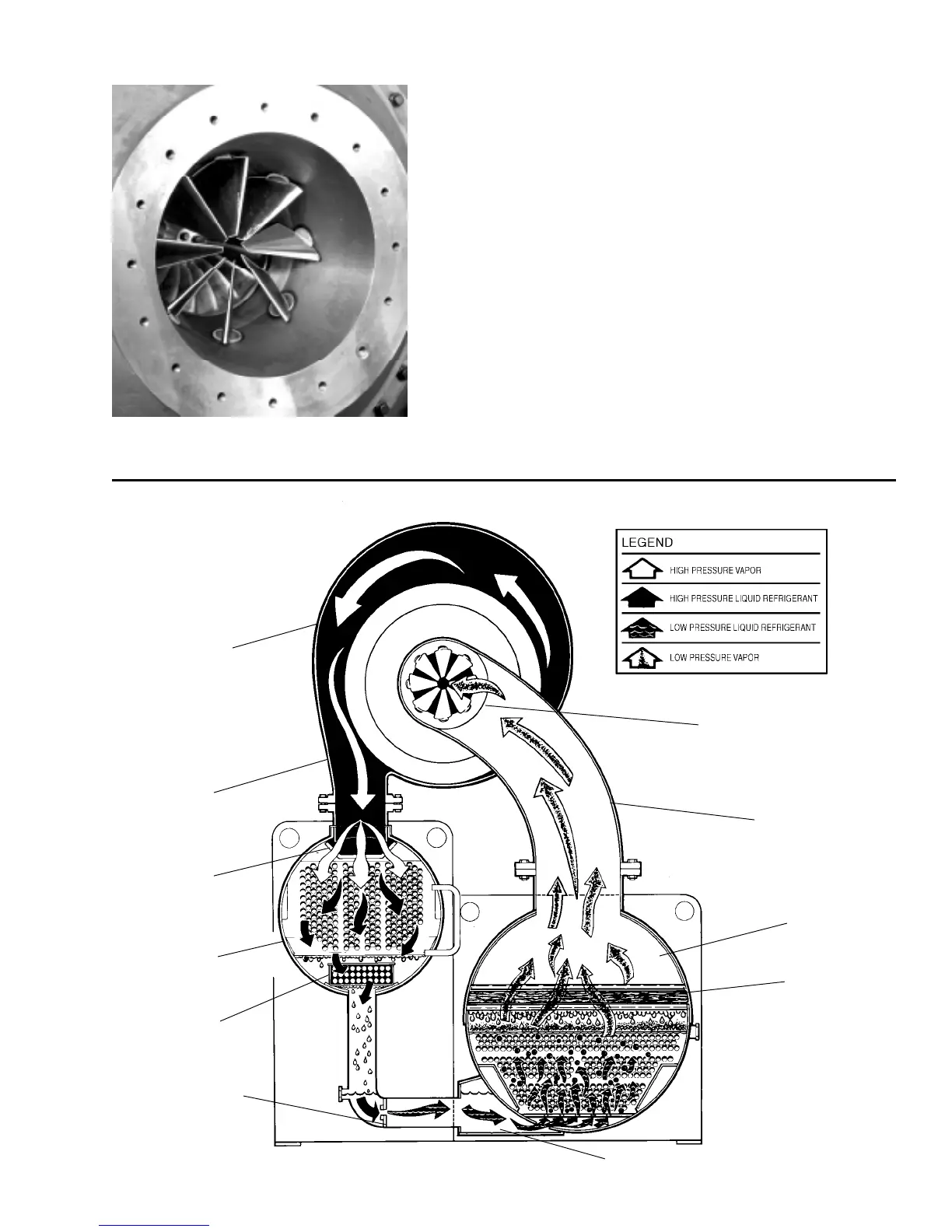

DETAIL A – COMPRESSOR PREROTATION VANES

design conditions. However, most systems will be called

upon to deliver full load capacity for only a relatively

small part of the time the unit is in operation.

CAPACITY CONTROL

The major components of a chiller are selected for full

load capacities, therefore capacity must be controlled to

maintain a constant chilled liquid temperature leaving

the cooler. Prerotation vanes (PRV), located at the en-

trance to the compressor impeller, compensate for varia-

tion in load (See Fig. 2. Detail A).

The position of these vanes is automatically controlled

through a lever arm attached to an electric motor lo-

cated outside the compressor housing. The automatic

adjustment of the vane position in effect provides the

performance of many different compressors to match

various load conditions from full load with vanes wide

open to minimum load with vanes completely closed.

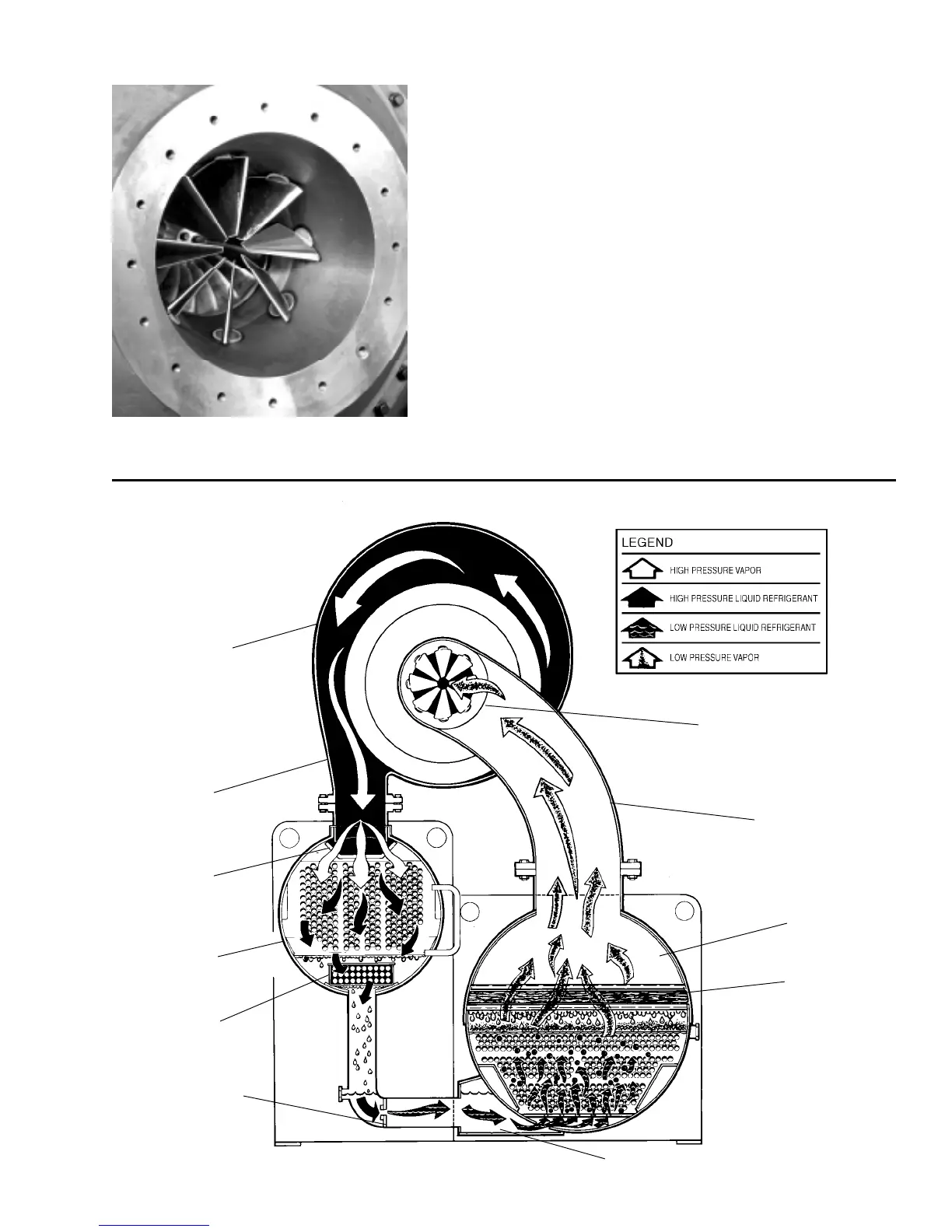

FIG. 2 – REFRIGERANT FLOW-THRU CHILLER

PREROTATION VANES

(See Detail A)

SUCTION

COOLER

ELIMINATOR

OIL COOLER

LD00924

FLOW CONTROL

ORIFICE

SUB-COOLER

CONDENSER

DISCHARGE

BAFFLE

DISCHARGE

COMPRESSOR

Loading...

Loading...