5

YORK INTERNATIONAL

FORM 201.19-EG4

LD05809

capacity.

• Automatic spring return of capacity control valve to

minimum load position ensures compressor starting

at minimum motor load. Internal discharge check to

prevent rotor backspin upon shut-down.

• Acoustically Tuned, internal discharge gas mufer

eliminates objectionable noise at the source, while

optimizing ow for maximum performance.

• Reliable suction gas cooled, high efciency, accessible

hermetic motor with APT2000 type magnet wire and

redundant overload protection using both thermistor

and current overload protection.

• Suction gas screen and serviceable, 0.5 micron full

ow oil lter within the compressor housing.

• Cast iron compressor housing precisely machined

for optimal clearances and superb efciency. Entire

compressor, from suction to discharge has a Design

Working Pressure of 450 PSIG (31 Bar).

• 350W compressor body cartridge heater.

REFRIGERANT CIRCUIT:

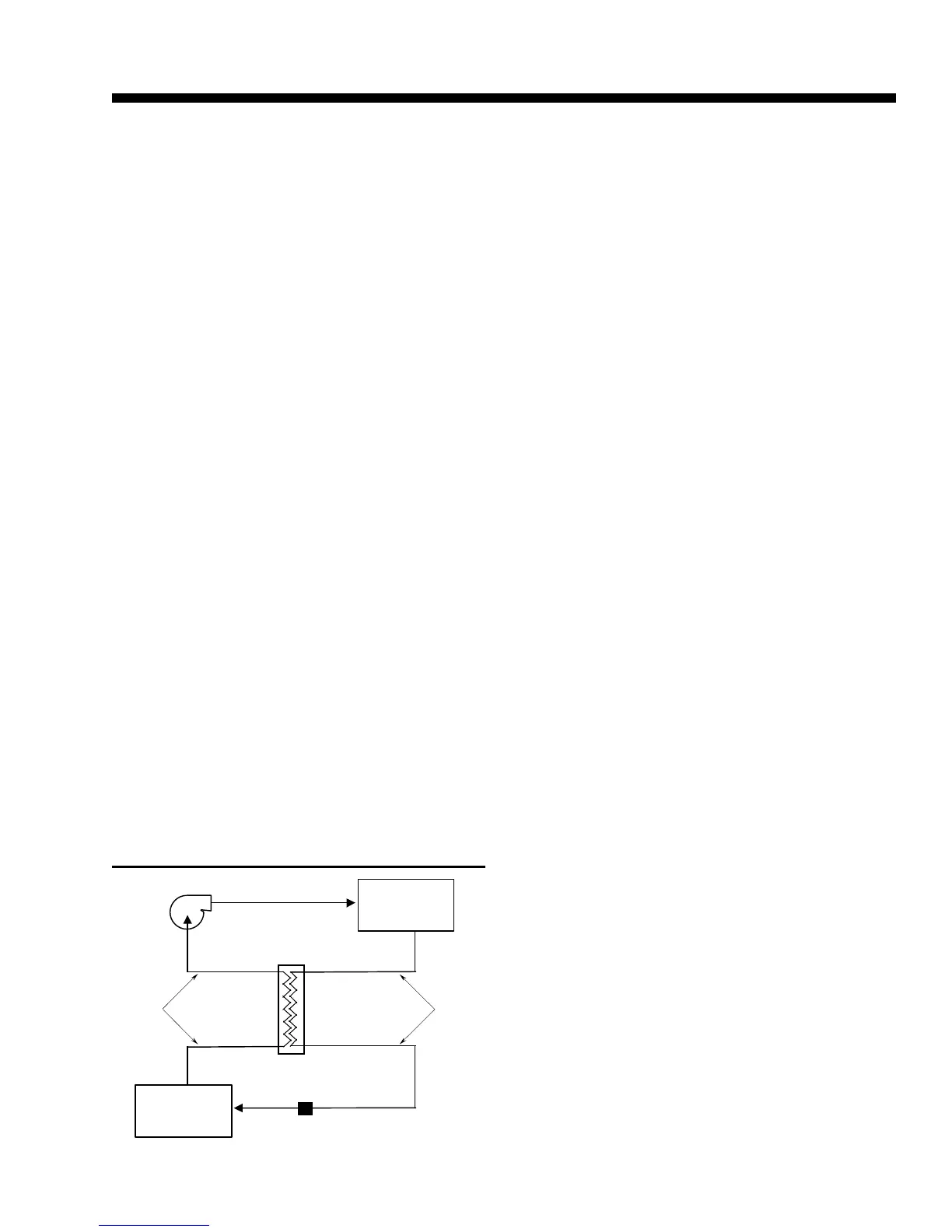

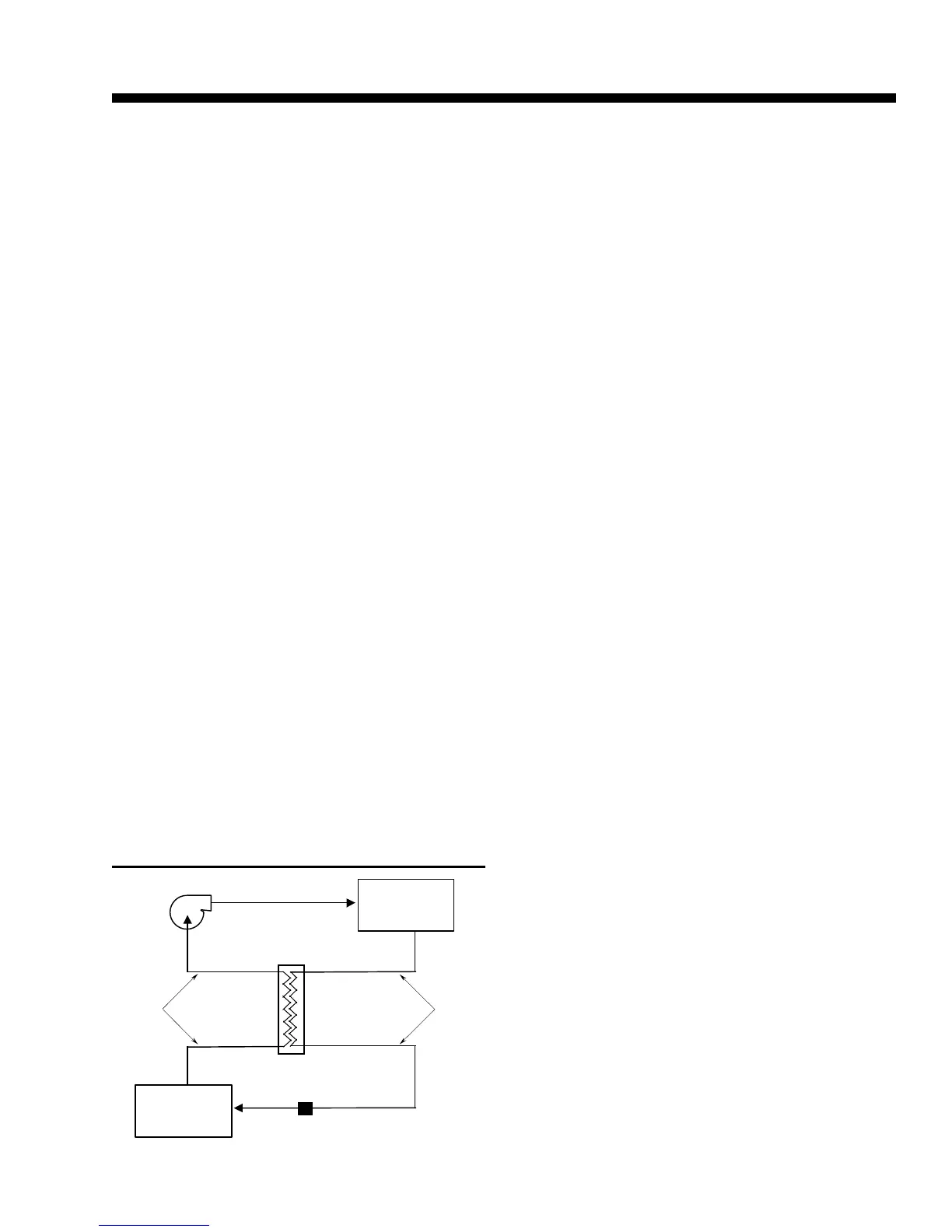

• Each refrigerant circuit of YORK’s eco

2

design utilizes

a Suction Line Heat Exchanger (SLHX), a refrigerant

to refrigerant, compact, shell and tube type heat ex-

changer to maximize chiller capacity and efciency by

subcooling liquid refrigerant delivered to the expansion

valve and superheating suction gas delivered to the

compressor. Design Working Pressure of 450 PSIG

(31 Bar) and either U.L./cU.L. listed or constructed

in accordance with applicable pressure vessel safety

Code (such as TÜV).

• Independent refrigerant circuits per compressor, each

using copper refrigerant pipe formed on computer con-

trolled bending machines. This eliminates over 60% of

system piping brazed joints as compared to designs

that use ttings, resulting in a highly reliable and leak

resistant system.

• Liquid line components include: manual shut-off valve

with charging port, high adsorption removable core

lter-drier, solenoid valve, sight glass with moisture-in-

dicator, and reliable thermostatic expansion valves.

• Discharge line provided with manual compressor shut-

off service valve (suction line shutoff valve optional).

Suction line equipped with closed-cell insulation.

• Oil separators with Design Working Pressure of 450

PSIG (31 Bar) and U.L. listing are high efciency,

augmented gas impingement type to maximize oil

extraction without fragile media to break down.

• Oil cooling provided by dedicated air cooled nned

tube type heat exchanger located in the condenser

section of the machine.

CONDENSER SECTION:

• Condenser Fans with low noise, full airfoil cross sec-

tion for maximum efciency, statically and dynamically

balanced vibration free operation, and positioned in

extended, formed steel orices for low sound and

maximum efciency.

• Condenser fan motors are high efciency, direct drive,

6-pole, 3-phase, Class-“F,” current overload protected,

totally enclosed (TEAO) type with double sealed, per-

manently lubricated ball bearings.

• Fin and tube condenser coils of seamless, internally

enhanced, high condensing coefcient, corrosion

resistant copper tubes arranged in staggered rows.

• Fins are mechanically bonded to corrosion resistant

aluminum alloy ns with full height n collars. Design

working pressure is 450 PSIG (31 Bar).

COMPLETE FACTORY PACKAGE:

• Each compressor is installed on its own independent

refrigerant circuit, which is factory pressure tested,

evacuated, then fully charged with refrigerant and

oil.

• After assembly, an operational test is performed with

water owing through the cooler to ensure each circuit

operates correctly.

• Cabinet and base frame are constructed of formed

heavy gauge, galvanized steel.

• All external structural parts are covered with archi-

tecturally neutral “Desert Sand” (Munsell #10YR6-2)

baked-on enamel powder paint. This provides a nish

which, when subjected to ASTM B117, 500 hour, 5%

salt spray conditions, shows breakdown of less than

1/8" either side of a scribed line (equivalent to ASTM

D1654 rating of “6”).

• Design is in accordance with applicable sec-

tions of ASME Pressure Vessel Code, NFPA

70 (National Electrical Code), U.L. and cU.L.

Loading...

Loading...