JOHNSON CONTROLS

150

FORM 150.67-NM1

ISSUE DATE: 4/28/2017

SECTION 6 – COMMISSIONING

5. Prior to this step, turn system 2 OFF (if applicable

–refer to Option 2 under “Unit Keys” section for

more information on system switches). Connect a

manifold gauge to system 1 suction and discharge

service valves.

Place the Unit Switch in the control panel to the

ON position. As each compressor cycles ON,

ensure that the discharge pressure rises and the

suction pressure decreases. If this does not oc-

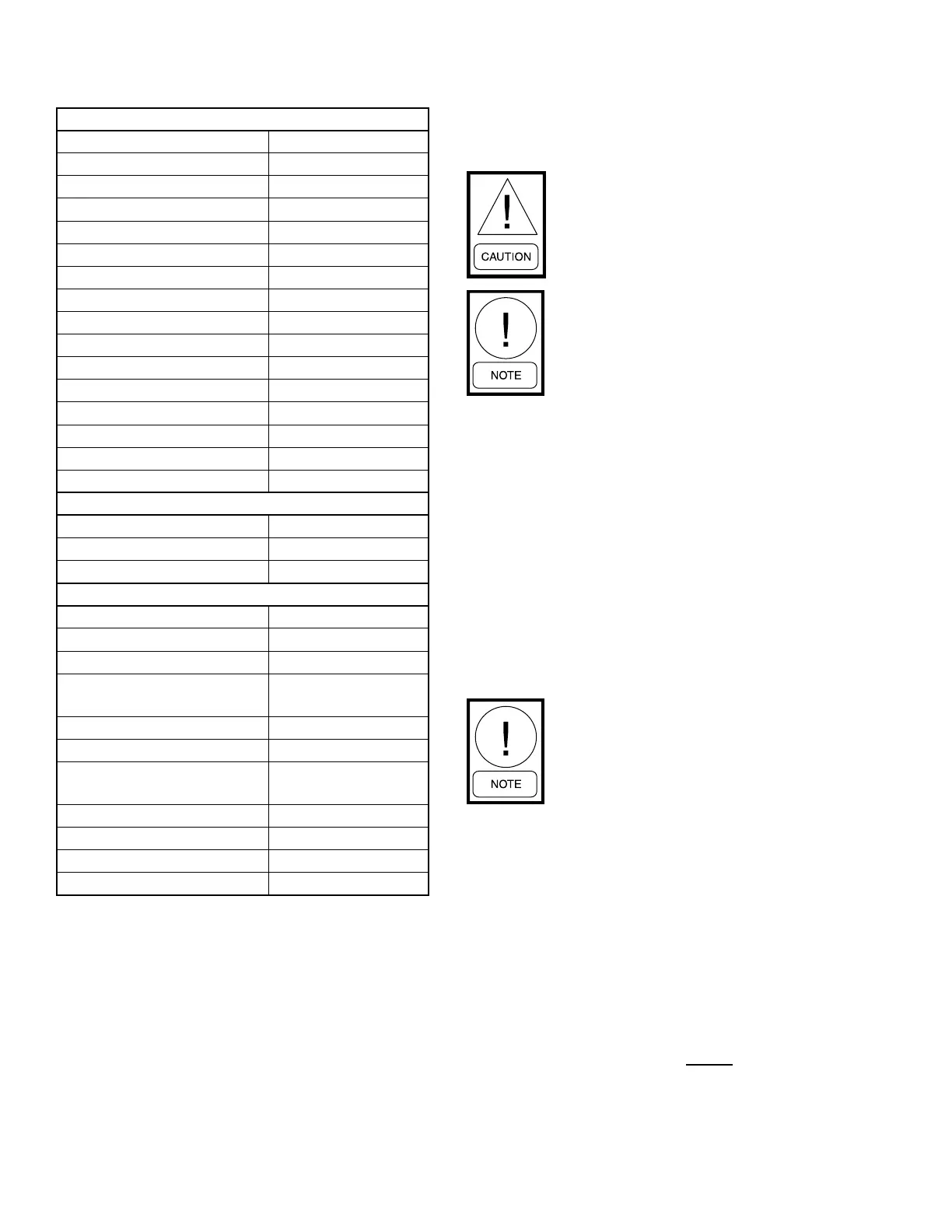

TABLE 10 - SETPOINTS ENTRY LIST

OPTIONS

Display Language

Sys 1 Switch

Sys 2 Switch

Chilled Liquid

* Ambient Control

Local/Remote Mode

Control Mode

Display Units

* Lead/Lag Control

* Fan Control N/A

Manual Override

Current Feedback

** Soft Start

** Unit Type

** Refrigerant Type

** Expansion Valve Type

COOLING SETPOINTS

Cooling Setpoint

Range

EMS-PWM Max. Setpoint

PROGRAM

Discharge Pressure Cutout

Suct. Pressure Cutout

Low Amb. Temperature Cutout

Leaving Liquid Temperature

Cutout

Anti-Recycle Time

Fan Control ON Pressure N/A

Fan Differential OFF Pres-

sure

N/A

Total # of Compressors

* Number of Fans/System N/A

* Unit/Sys Voltage

Unit ID

* Not on All Models

** Viewable Only

cur, the compressor being tested is operating in

the reverse direction and must be corrected. After

verifying proper compressor rotation, turn the

Unit Switch to OFF.

The chilled liquid setpoint may need

to be temporarily lowered to ensure all

compressors cycle ON.

This unit uses scroll compressors

which can only operate in one direc-

tion. Failure to observe this will lead

to compressor failure.

6. YCAL0043 – YCAL0066 units only – Turn sys-

tem 1 OFF and system 2 ON (refer to Option 2

under “Unit Keys” section for more information

on system switches).

Place the Unit Switch in the control panel to the

ON position. As each compressor cycles ON,

ensure that the discharge pressure rises and the

suction pressure decreases. If this does not oc-

cur, the compressor being tested is operating in

the reverse direction and must be corrected. After

verifying proper compressor rotation, turn the

Unit Switch to OFF.

The chilled liquid setpoint may need

to be temporarily lowered to ensure all

compressors cycle ON.

CHECKING SUPERHEAT AND SUBCOOLING

The subcooling temperature of each system can be cal-

culated by recording the temperature of the liquid line

at the outlet of the condenser and subtracting it from

the liquid line saturation temperature at the liquid stop

valve (liquid line saturation temperature is converted

from a temperature/pressure chart).

Example:

Liquid line pressure =

325 PSIG converted to temp. 101 °F

minus liquid line temp. - 86 °F

Subcooling = 15 °F

The subcooling should be adjusted to 15 °F at design

conditions.

Loading...

Loading...