Loading...

Loading...

Do you have a question about the York YLAA and is the answer not in the manual?

| Model | YLAA |

|---|---|

| Condenser | Air-Cooled |

| Efficiency | High Efficiency |

| Sound Pressure Level | Varies by model (typically 70-85 dB) |

| Dimensions | Varies by model |

| Weight | Varies by model |

| Category | Air-Cooled Scroll Chiller |

| Voltage | 208-575V, 3-phase, 50/60 Hz |

Discusses factory assembly, single-point connection, and simple piping.

Highlights proven scroll compressors and corrosion-resistant heat exchangers.

Covers high-efficiency and standard models, and IPLV performance.

Details options for glycol cooling, heat recovery, and pump configurations.

Focuses on R-410A refrigerant and reduced refrigerant charge for eco-friendliness.

Explains native BACnet, Modbus, N2 capabilities and optional LON.

Describes ease of maintenance, component accessibility, and cleaning.

Details testing and third-party verification of chiller performance.

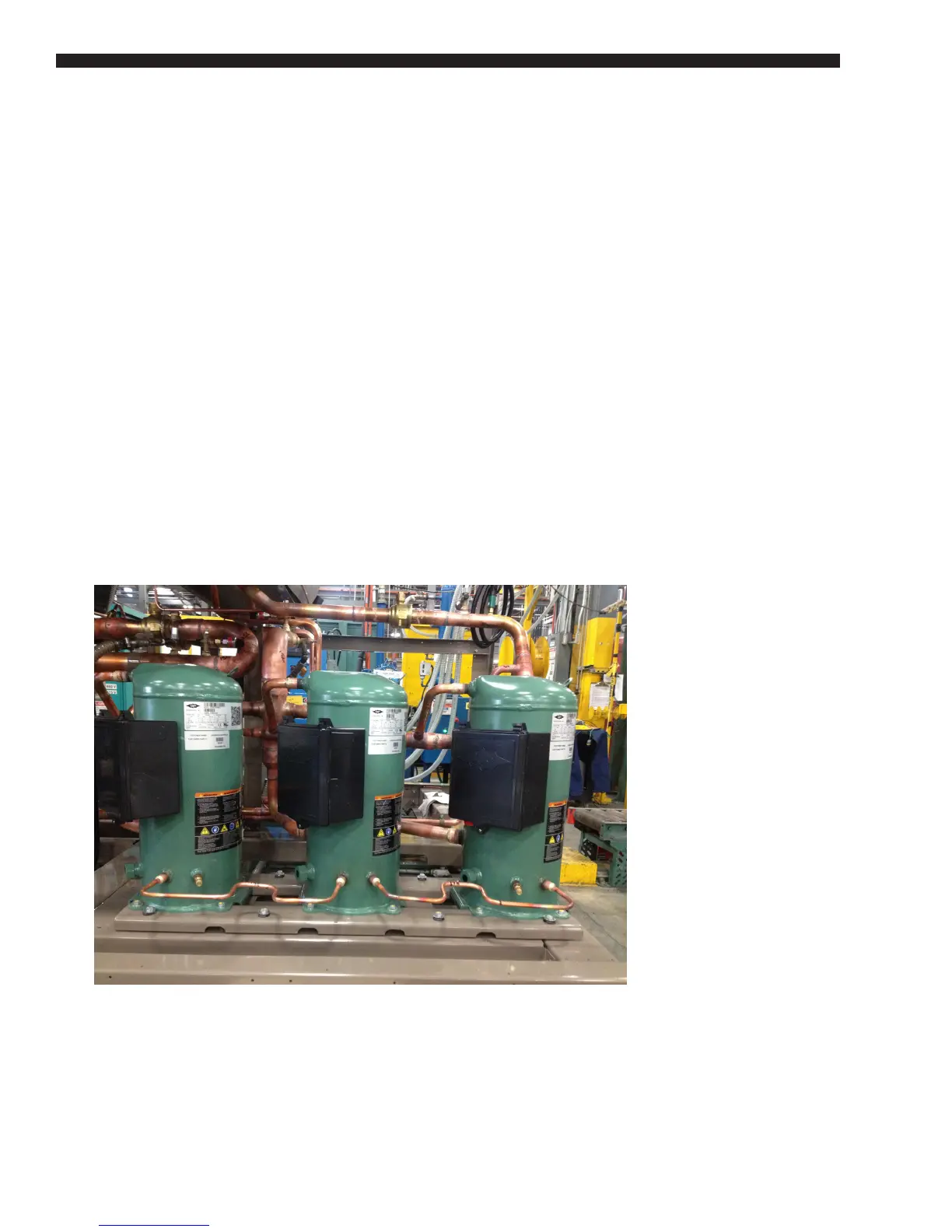

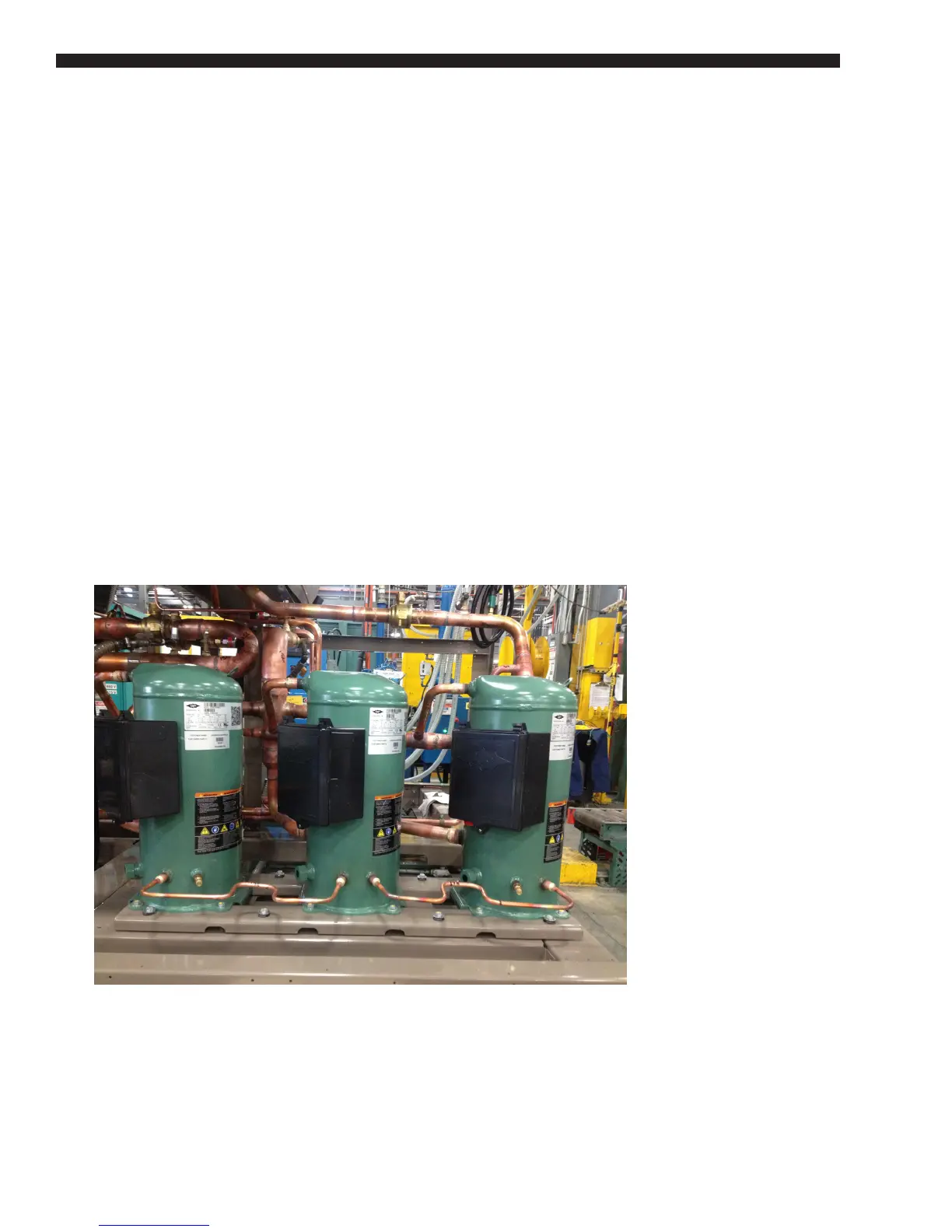

Describes hermetic scroll compressors with compliant design and balanced rotating parts.

Details the compact, high-efficiency Brazed Plate Heat Exchanger construction.

Lists Canadian Registration Numbers (CRN) for YLAA brazed plate evaporators.

Describes condenser coils construction and fan details for performance.

Explains the intelligent control system for automatic operation and reliability.

Provides quick access to operating data and system information.

Allows entering setpoints or modifying system values and parameters.

Lists standard BACnet, Modbus, N2 capabilities for building automation.

Explains connection to Johnson Controls BAS via RS232 for system integration.

Describes the contents of the power panel, including contactors and protection.

Details available options for unit power connections and disconnects.

Lists options for ambient temperature control and language display.

Covers options for low-temp glycol, heat recovery, and hydro-kit configurations.

Describes options for condenser coil protection against corrosive environments.

Details options for reducing operational noise for sensitive locations.

Presents options for vibration isolation mounts for unit stability.

Details wiring inputs for remote temperature reset, flow switch, and remote start/stop.

Lists wiring outputs for evaporator heater, solenoid valves, and alarm contacts.

Provides guidance on selecting a suitable outdoor installation site.

Specifies requirements for level and stable foundation for unit mounting.

Advises on flow rate changes and system volume for VPF applications.

Guides on proper layout and component selection for chilled liquid piping.

Outlines the general requirements and scope of the chiller system.

Lists applicable standards and codes for product design and installation.

Covers requirements for unit delivery, shipment, storage, and handling.

Specifies materials, construction, and basic components of the chiller.

Details hermetic scroll compressor specifications and features.

Lists essential components within each refrigerant circuit.

Describes the brazed plate evaporator construction and features.

Details the microprocessor's functions, display, and keypad.

Lists configurable setpoints for language, temperature, and schedules.

Describes the data points available on the unit display for monitoring.

Lists system safeties that cause automatic shutdown and require manual reset.

Details automatic safeties causing shutdown for ambient, temperature, and voltage issues.

Specifies standard and optional communication protocols for BAS integration.

Introduces available accessories and options that enhance functionality.

Covers factory-installed options for reducing operational noise levels.

Lists field-installed options for vibration isolation mounts.

Details general requirements for rigging, installing, and leveling the chiller.