JOHNSON CONTROLS

14

Form 160.78-O1

Issue date: 05/19/2021

Section 2 - System operating procedures

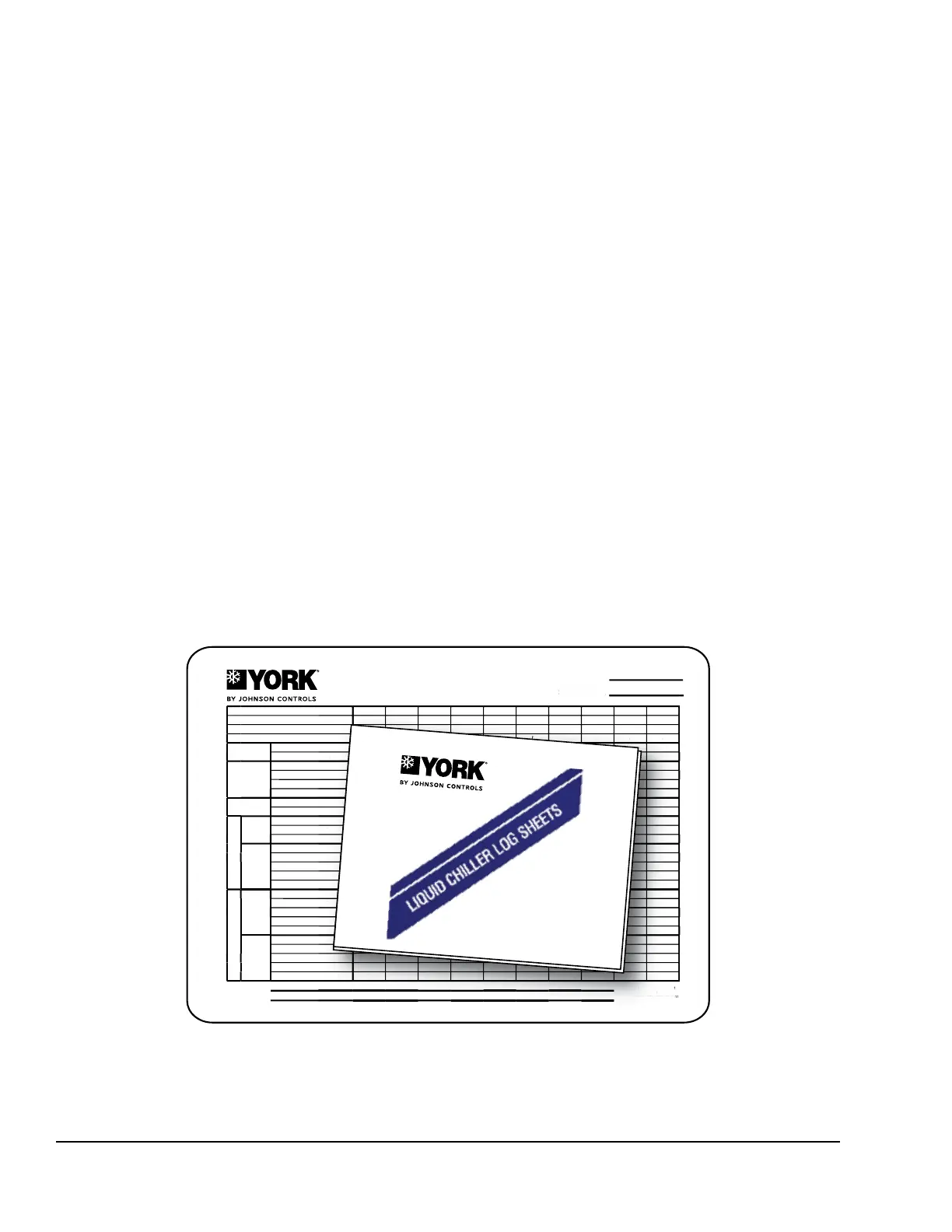

is available for this purpose. Figure 4 shows an ex-

ample log sheet used by Johnson Controls Personnel

for recording test data on chiller systems. Log sheets

are available in pads of 50 sheets and can be obtained

through the nearest Johnson Controls office. Request

the YMC

2

Centrifugal Liquid Chiller Log Sheets (Form

160.78-MR1).

An accurate record of readings serves as a valuable ref-

erence for operating the system. Readings taken when

a system is newly installed will establish normal condi-

tions with which to compare later readings.

For example, an increase in condenser approach tem-

perature (condenser temperature minus leaving con-

denser water temperature) may be an indication of

dirty condenser tubes.

Operating inspections

By following a regular inspection using the display

readings of the OptiView™ Control Center, and main-

tenance procedure, the operator will avoid serious op-

erating difficulty. The following list of inspections and

procedures should be used as a guide.

Daily

1. Check OptiView™ Control Center displays.

2. Check entering and leaving condenser water pres-

sure and temperatures for comparison with job

design conditions. Condenser water temperatures

can be checked on the SYSTEM Screen.

3. Check the entering and leaving chilled liquid tem-

peratures and evaporator pressure for compari-

son with job design conditions on the SYSTEM

Screen.

4. Check the condenser saturation temperature on

the SYSTEM Screen.. This temperature is based

on the condenser pressure that is detected by the

condenser transducer.

5. Check the compressor discharge temperature on

the SYSTEM Screen. During normal operation

discharge temperature should not exceed 220°F

(104°C).

6. Check the compressor motor current on the SYS-

TEM Screen.

Figure 4 - Liquid chiller log sheets

CENTRIFUGAL

LIQUID CHILLER LOG SHEET

Chiller Location

System No.

Date

Time

Hour Meter Reading

O.A. Temperature Dry Bulb / Wet Bulb / / / / / / / / / /

Compressor

Discharge Temperature

PRV % Open (If equipped)

Motor

Input Power

% Input FLA

% Motor FLA

DC Bus Voltage

Magnetic Bearing

Controller

Motor Housing Temperature

Rotor Elongation

Evaporator

Refrigerant

Suction Pressure

Corresponding Temperature

Small Temperature Difference

Liquid

Supply Temperature

Supply Pressure

Return Temperature

Return Pressure

Flow Rate - GPM (If equipped)

Condenser

Refrigerant

Discharge Pressure

Corresponding Temperature

Subcooler Liquid Temperature

Small Temperature Difference

Refrigerant Level

Liquid

Supply Temperature

Supply Pressure

Return Temperature

Return Pressure

Flow Rate - GPM (If equipped)

Remarks:

Form 160.78-MR1 (611)

New Release

Issue Date: June 30, 2011

...an Energy-Saving

approach to your

Service needs...

Issue Date:

June 30, 2011

Form 160.78-MR1 (611)

New Release

YMC

2

CENTRIFUGAL

LD16236

* NOTE: A pad of 50 log sheets can be ordered from your local Johnson Controls branch by

requesting Form 160.78-MR1.

Loading...

Loading...