2.2 Process interface ESAB, robot 2, B_AW_PROC_41

I/O board configuration, robot 2

This chapter describes the standard process configuration delivered by ABB

Robotics. Process Interface DeviceNet for ESAB Aristo™ Mig and W8.

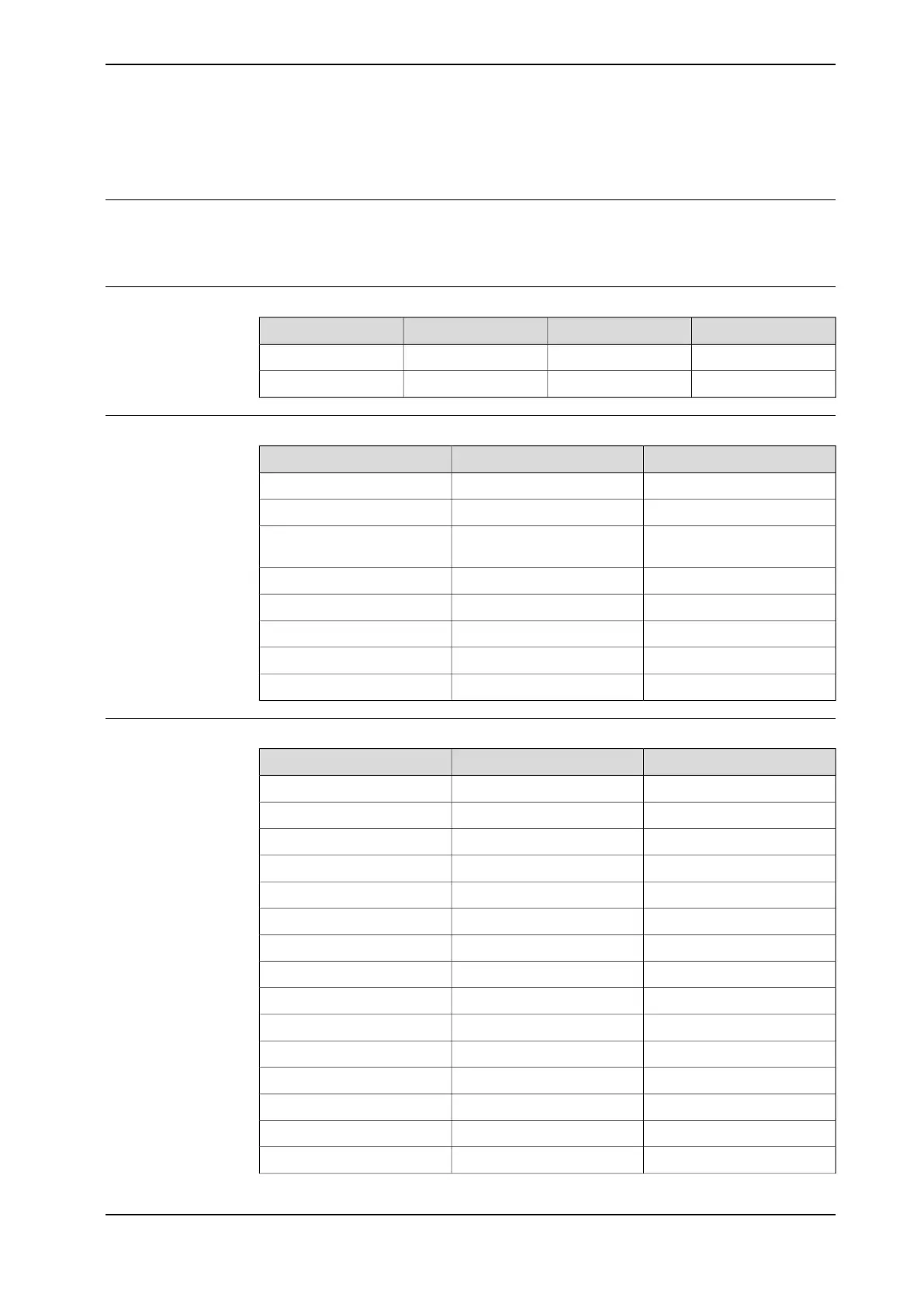

Board configuration

BusBoard typeNameAddress

CAN DeviceNetESAB_W8B_AW_PROC_4141

VirtualSimulated digital I/OB_SIM_AW

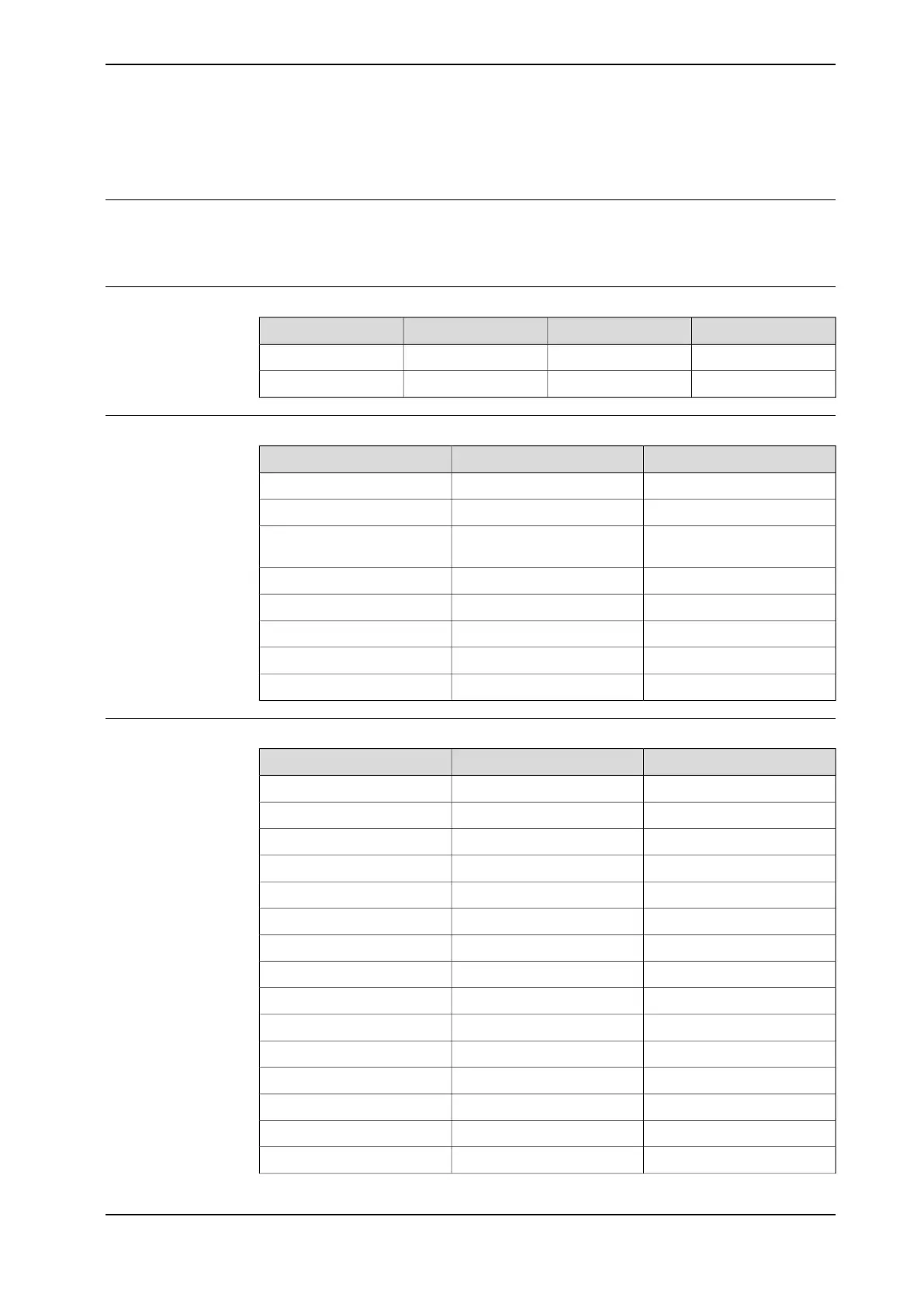

Digital outputs

DescriptionNameDevice Map

Activate power sourcedoWeld_20

Quick stop of power sourcedoQuickStop_21

Emergency stop of power

source

doEmStop_22

Activate wire feederdoFeed_23

Activate gas valvedoGas_24

Activate air cleaning of torchdoAir_25

Activate wire feeder reversedoFeedBwd_26

Activate tactile search modedoTouchSenseActive_215

Digital inputs

DescriptionNameDevice Map

Arc establisheddiArcEst_248

Weld establisheddiWeldEst_249

Search contact establisheddiTouchSenseContact_250

Wire feed unit 1 selecteddiWF1Selected_252

Wire feed unit 2 selecteddiWF2Selected_253

Wire feed unit 3 selecteddiWF3Selected_254

Wire feed unit 4 selecteddiWF4Selected_255

Error codediError1_256

Error codediError2_257

Error codediError3_258

Error codediError4_259

Error codediError5_260

Error codediError6_261

Error codediError7_262

Error codediError8_263

Continues on next page

Application manual - Signal description for arc welding products 15

3HAC050975-001 Revision: -

© Copyright 2004-2016 ABB. All rights reserved.

2 Signal configuration

2.2 Process interface ESAB, robot 2, B_AW_PROC_41

Loading...

Loading...