________________________________________________________________________________________________________

AC500-eCo - 17 -

Hardware Introduction

3.2 Wiring

Wiring cautions

4.1

• Do not lay I/O signal cables next to power cables or allow them to share the same trunk duct.

Low voltage cables should be reliably separated or insulated with regard to high voltage cabling.

• Where I/O signal lines are used over an extended distance consideration for voltage drop and

noise interference should be made.

• Do not lay signal cables near high voltage power cabling or cabinet housing along the same

trunk duct. Effects of noise or surge induction may occur.

• Replace the terminal cover provided, after installation or wiring work is completed, and before

supplying power and operating the unit to avoid electric shock.

• When performing incorrect wiring or operation, serious damage will occur.

3.2.1 Power Supply Wiring

AC500 CPUs PM554 and PM564 use two kinds of power supply voltage:

1. 24VDC

2. 100~240VAC.

IMPORTENT

For 24V DC variant, exceeding the maximum power supply voltage (>30V DC)

for process or supply voltages could lead to unrecoverable damage of the

system. The system could be destroyed.

CAUTION

Removal of energized modules is not permitted. All power sources (supply

and process voltages) must be switched off while working on any AC500

system.

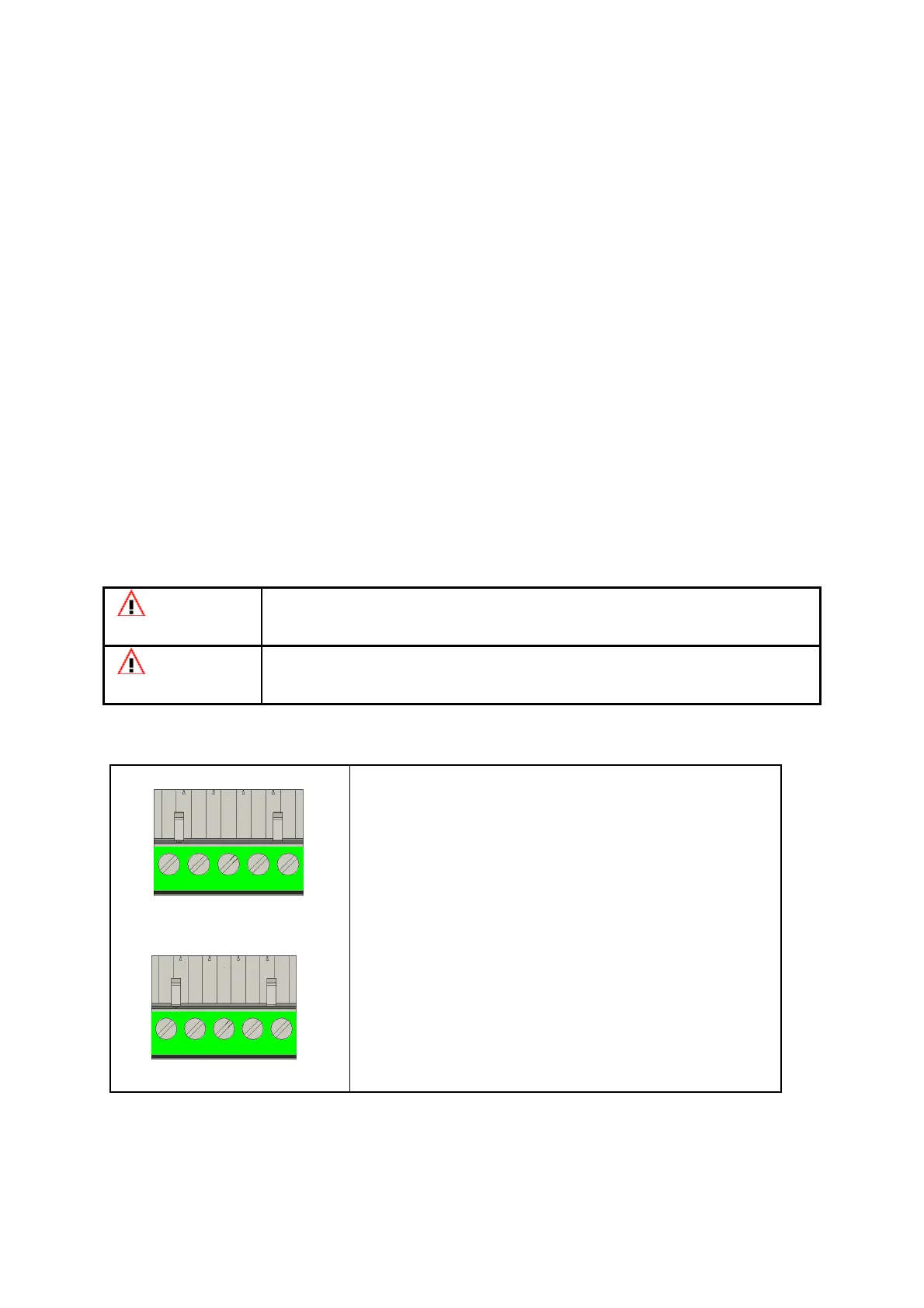

24V DC

L+ M FE L+ M

24V 0V FE 24V 0V

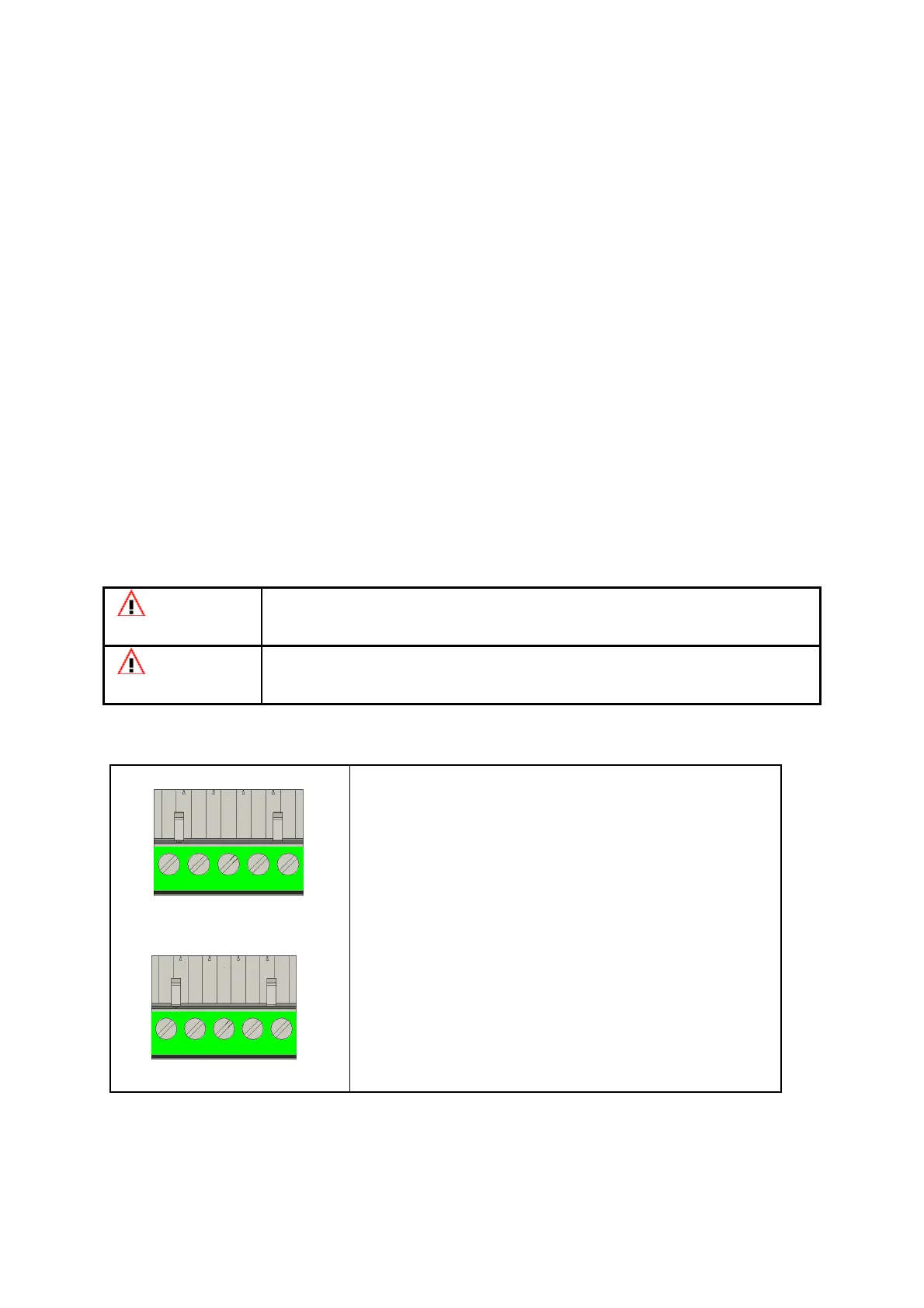

100-240V AC

The supply voltage 24V DC is connected to a 5-pin

removable terminal block. The 5 pins from left to right

are L+, M, FE, L+ and M. L+ and M exist twice, so it is

possible to supply external sensors from this terminal.

FE is for functional earth.

The supply voltage 100~240V AC is also connected

to a 5-pin removable terminal block. The 5 pins from

left to right are L, N, FE, L+ and M. FE is for functional

earth. L and N are connected to AC power supply

source. L+ and M are internal voltage outputs 24V DC

and 0V. They are used for external modules.

L N FE L+ M

0V FE 24V 0V

100~240

Loading...

Loading...