Maintenance

42/68-167-EN RHDE250 ... 4000 (Contrac) 35

Pos: 17.1 /Überschri ften/1/S - Z/War tung @ 10\mod_1181642125390_310 1.doc @ 103817

7 Maintenance

Pos: 17.2 /Wartung / Repara tur/Aktorik/ Antriebe/Allgemein/ Wartung @ 10\mod_11816402 90218_3101.doc @ 103695

Important

All maintenance activities may only be performed by properly qualified persons.

Contrac actuators feature a robust construction. As a result, they are highly reliable and require

minimal maintenance. The maintenance intervals depend upon the effective load and are

therefore not specified here.

The built-in microprocessor evaluates the actual load factors (e.g. torques, forces,

temperatures, etc.) and derives the remaining operating time until the next routine maintenance

is required.

Use the configuration program to view this information.

Pos: 17.3 /Überschri ften/1.1/1-spa ltig/G - L/Inspektion und Über holung @ 10\mod_1181642 170921_3101.doc @ 10384 0

7.1 Inspection and overhaul

Pos: 17.4 /Wartung / Repara tur/Aktorik/ Antriebe/Elektr. Sc hwenkantriebe/Allge mein/Inspektion und Überholung @ 10\mod_118164 0404046_3101.doc @ 103748

• Only use genuine spare parts such as ball bearings, gaskets and oil may be used to

overhaul the actuators.

• Proceed acc. to table when performing maintenance activities.

• Inspection or maintenance is due after the time specified in the table.

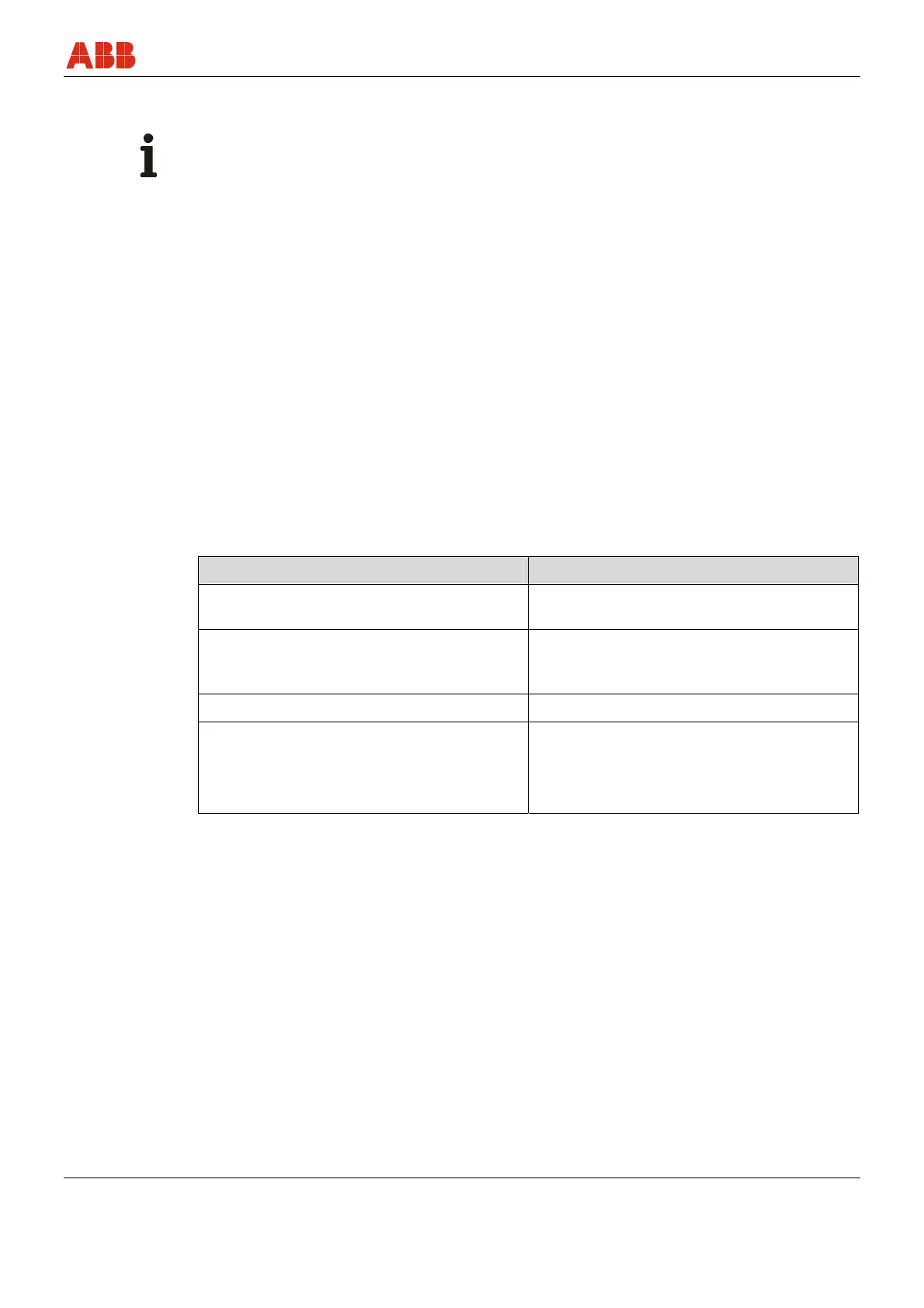

Overhaul intervals:

Interval Measures

1 x per year Visual check of the gaskets for leaks, change

if necessary.

every 2 years Functional check: drive the actuator 2 x

through the entire stroke range and check for

correct speed reduction.

every 4 years Check oil level

Change oil, roller bearings and gaskets on

motor and gearing.

max. every 10 years, preferably after the

expiry of the calculated remaining service life

Check gear wheels for wear; replace if

necessary.

Don’t drive the actuator during the oil check.

Make sure that no chippings or other material get into the gearbox during the maintenance

work.

If the actuators are used within a II2D classified area, clean the surfaces regularly in order to

avoid dirt deposits of more than 5 mm (0.20 inch). In order to avoid electrostatic charging use a

damp cloth to clean the lacquered surfaces.

Pos: 17.5 /====== = Seitenumbruch ======= = @ 0\mod_1126532365768_3101.doc @ 3830

Loading...

Loading...