37

7.3. Inspection

– Carry out regular inspections to check that the interruption

devices are in good condition.

– The checks must include a visual inspection to find any

contamination,tracesofcorrosionorelectricaldischarge

phenomena(accordingtowhatisprescribedintable4.

–Whenthereareunusualserviceconditions(including

adverse climatic conditions) and/or in the case of

environmentalpollution(e.g.heavycontaminationoran

atmospherewithaggressiveagents),thefrequencyof

inspections must be increased.

– Visual examination of the main contacts. The contact

areas must be cleaned if there are signs of overheating

(discolouredsurface)(alsoseetheparagraphon“Repairs”).

Ifanyanomalousconditionsarefound,appropriate

maintenancemeasuresmustbetaken(seethe“Servicing”

paragraph).

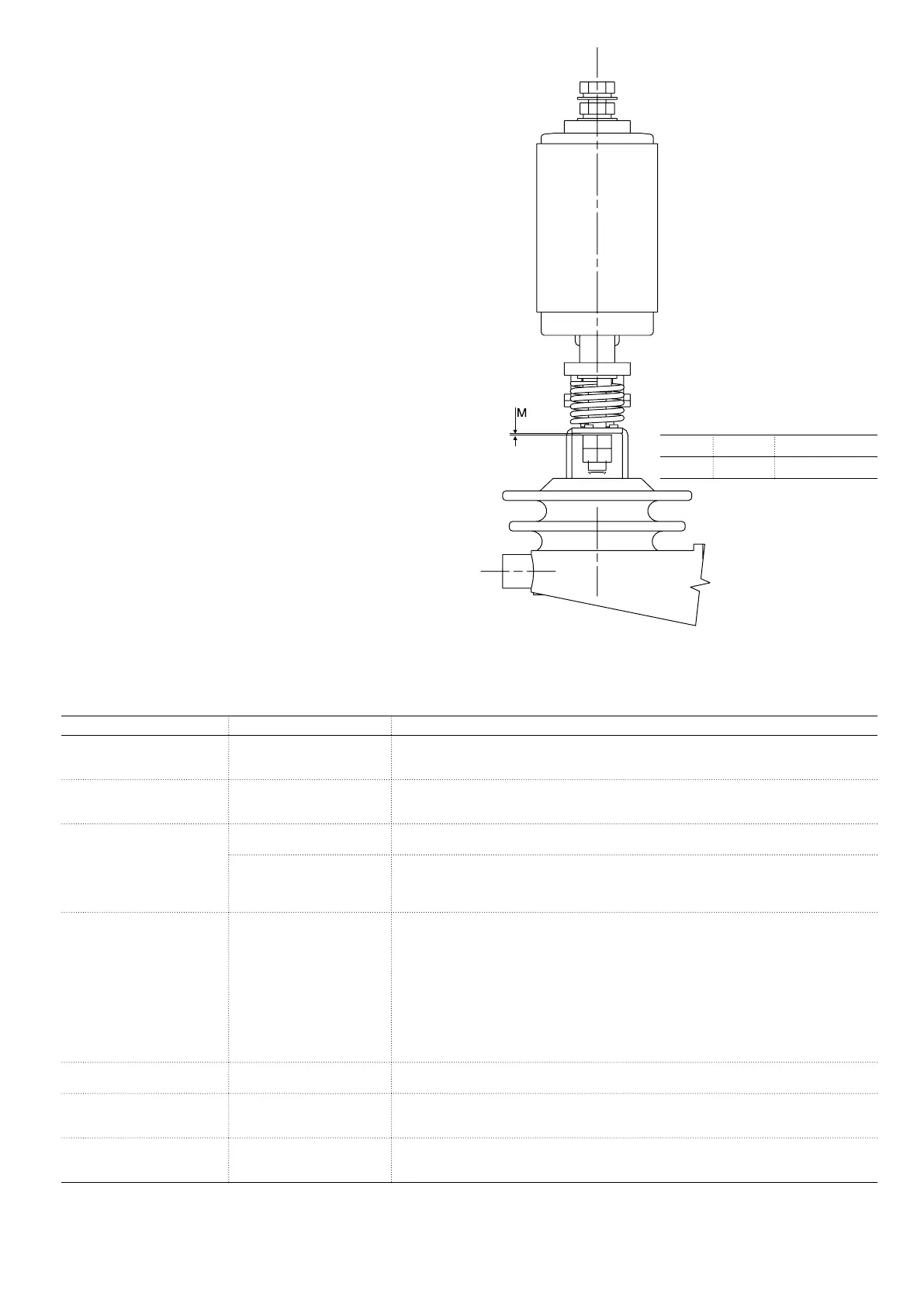

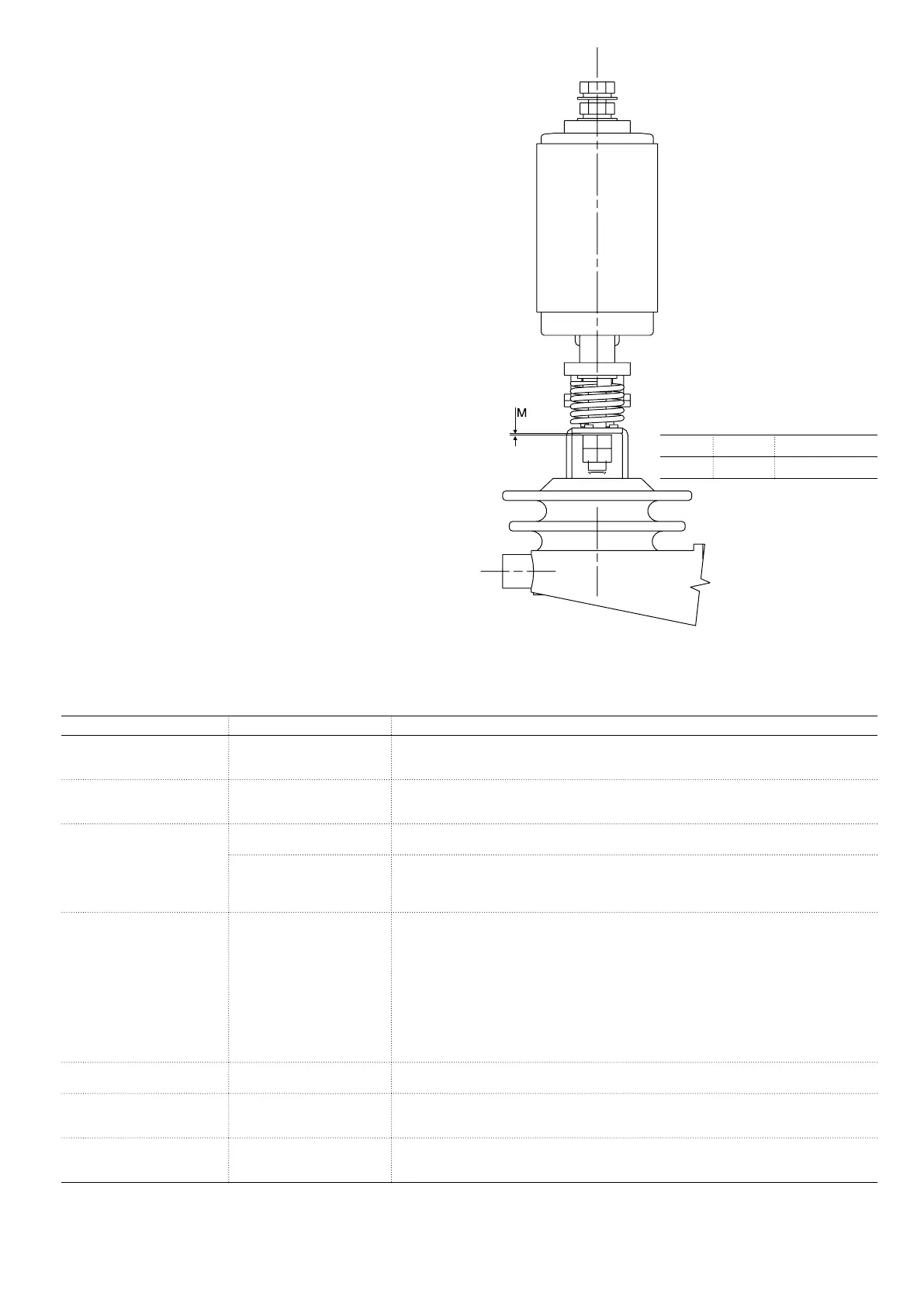

Fig. 17

VSC 7 VSC 12 / VSC-S

M [mm] 1.5...2 1.3...1.7

TABLE 4

Item to be inspected Interval Operation to be carried out

1 Insulating parts. 1 year or

50,000operations.

Visual inspection of the insulating parts. The insulating parts must be free of any

accumulationofdust,humidity,dirt(clean),cracks,tracesofsurfacedischargesor

damage.

2 Structure.. 1 year or

50,000operations.

Visual inspection of the structure and mechanisms. The components must be free of any

deformation,accumulationofdust,dirtordamage.Thescrews,nutsandboltsmustbe

correctly tightened. Avoid touching the ceramic surface.

3

Interrupter. 1 year or

50,000operations.

Checkthattheinterrupterisfreeofaccumulationofdust,dirt(clean),cracks(replace),

traces of surface discharges or damage.

In case of accidental

impacts.

Carry out a voltage test with the contacts open at 15 kV - 50 Hz for one minute. If there

isadischargeduringthetest,theinterruptermustbereplacedbecausethistypeof

phenomenoncorrespondstodeteriorationinthedegreeofvacuum.Incaseofneed,

contact ABB Service.

4

Interrupter contacts. 1 year or

50,000interruptionsatthe

rated current.

Refer to fig. 17.

The contact material vaporises from the surfaces during each interruption and condenses

elsewhereinsidethevacuuminterrupter.Thisisanormalprocess,andisforeseenbythe

overrun,orbytheweartolerance.

Asthecontactswear,theoverrundistance“M”decreases.

Whendistance“M”,ofanypole,goesbelow0.5mmwiththecontactorintheclosed

position,allthesub-assembliesmustbereplaced.

Use a fork-shaped gauge 0.5 mm thick to carry out this measurement.

Caution! Never attempt to adjust the nuts of the vacuum interrupters for any reason

whatsoever.

Theoverrundistancemustbechecked,butnotadjusted.

5

Auxiliary contacts. 1 year or

50,000operations.

Check correct operation and the signals. Check that there are no burnt or worn contacts

(replace).

6

Auxiliary circuit

conductors.

1 year or

50,000operations.

Check whether any cabling straps are loose or broken and check connection tightness.

Examine all the wire or cable connections to make sure that none of them are loose and

that there is no overheating.

7

Visual inspection of

the isolating contacts

(withdrawablecontactors)

5 years. The isolating contacts must be free of any deformation or erosion.

Lubricate the contact elements with 5RX Moly type grease.

NEPSI.COM - Northeast Power Systems. Inc.

Loading...

Loading...