4

1. Description

The medium voltage V-Contact VSC contactors are pieces

of apparatus suitable for operating in alternating current and

are normally used to control users requiring a high number of

hourly operations.

The basic contactors consist of:

•mouldedpolyesterresinmonobloccontainingthevacuum

interrupters

•bistableelectromagnetactuator

•multi-voltagefeeders

•auxiliarycontacts

•mechanicalstatusindicator(open/closed)

•manualemergencyopeningdevice.

Apartfromwhatisspecifiedforthefixedcontactors,the

withdrawable contactors also consist of:

•fuseholderspresetforDINorBSfuses(accordingtothe

customer’srequirements)

•automaticopeningdeviceforinterventionofevenasingle

fuse

•truck

•lockwhichpreventsclosingduringtheracking-in/out

operation.

The V-Contact VSC contactor introduces the drive with

permanentmagnets-alreadywidelyused,experimented

and appreciated in medium voltage circuit-breakers - into the

worldwide panorama of medium voltage contactors.

The experience acquired by ABB in the field of medium

voltage circuit-breakers fitted with drives with “MABS”

permanentmagnets,hasmadeitpossibletodevelopan

optimisedversionoftheactuator(BistableMACdrive)for

medium voltage contactors.

The drive is operated by means of an electronic feeder able

to cover all the power supply voltages required by the major

international Standards.

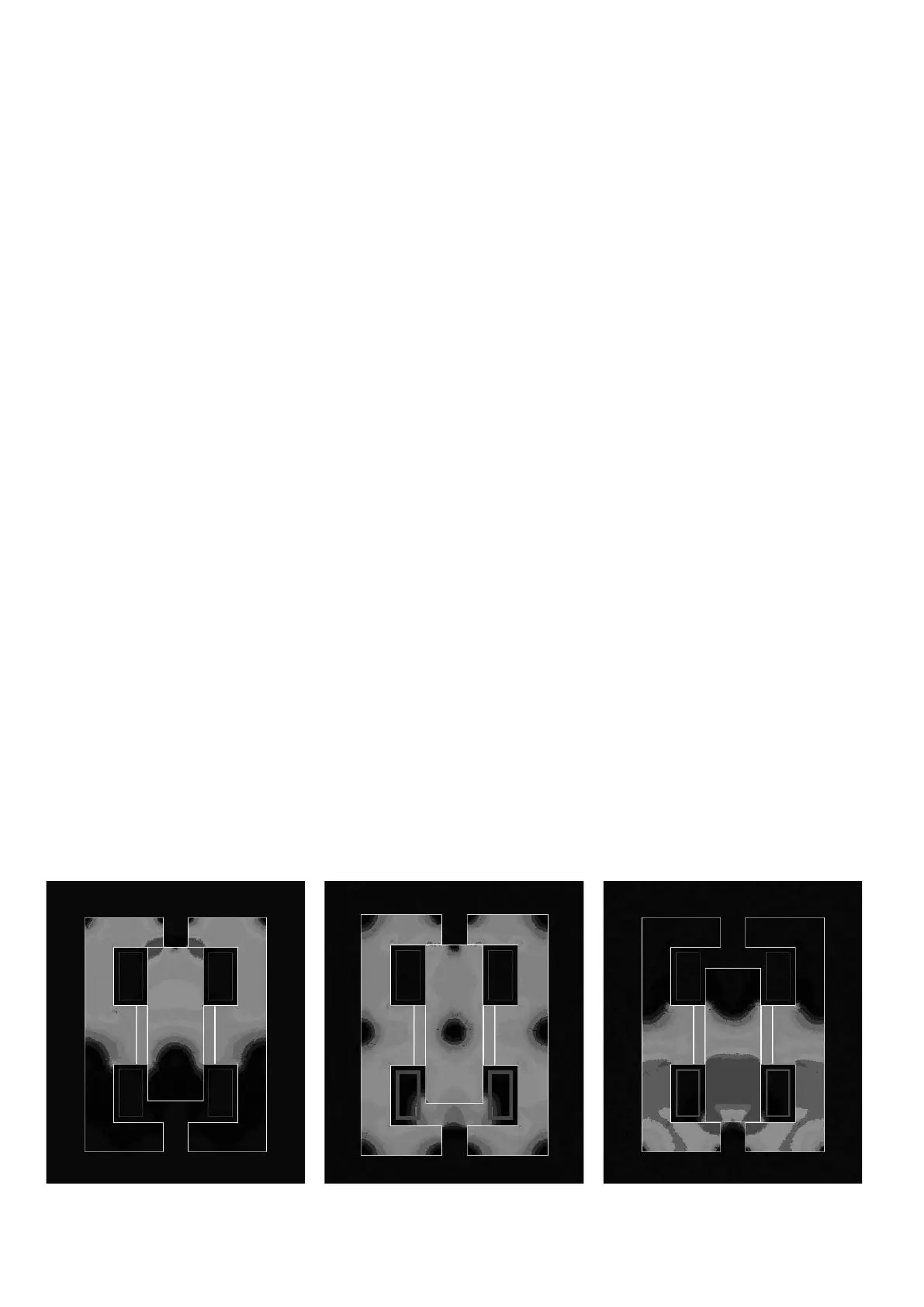

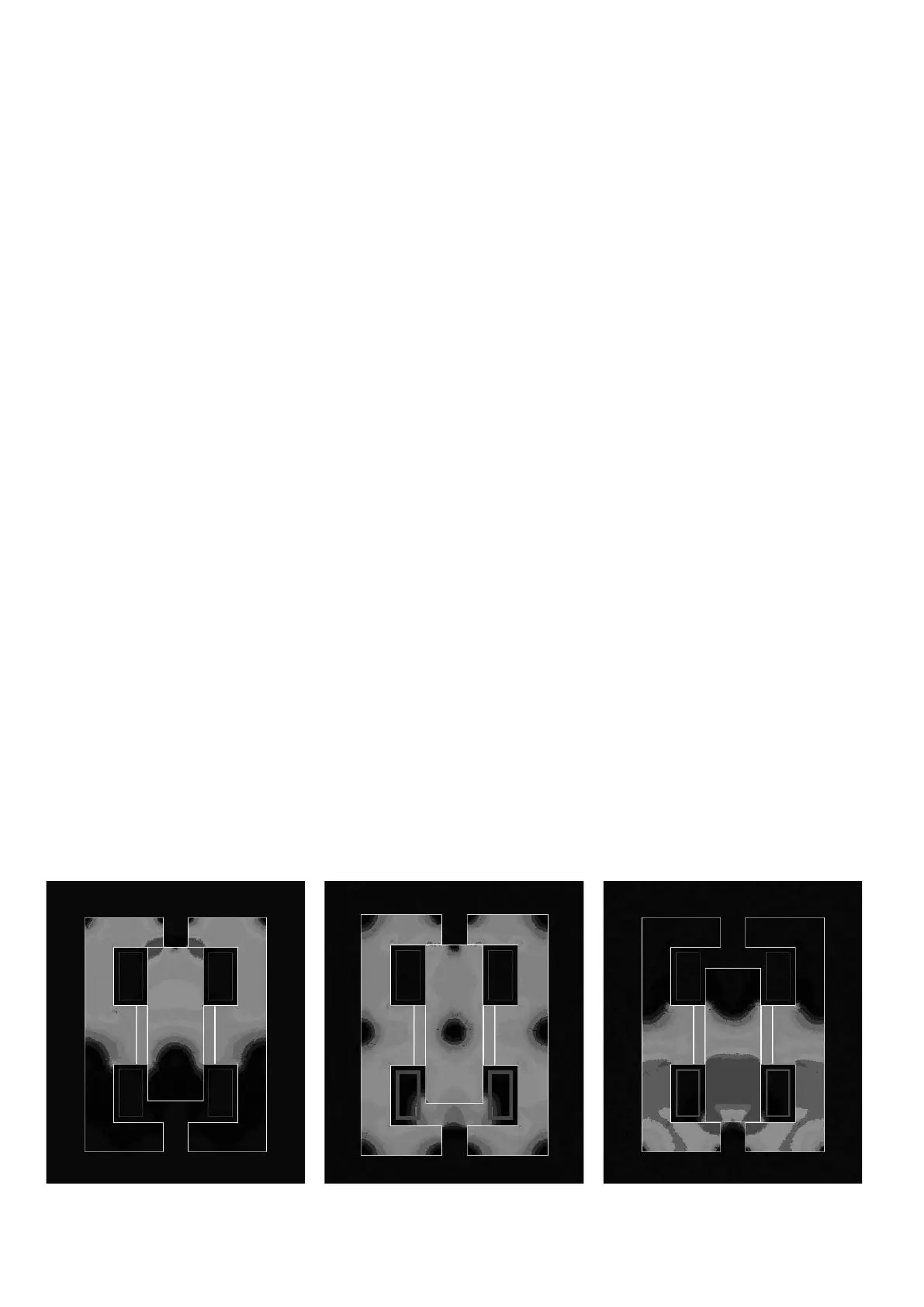

Fig. A

Magnetic circuit in the closed position.

Fig. B

Magnetic circuit with opening coil supplied.

Fig. C

Magnetic circuit in the open position.

1.1. “MAC” magnetic drive

Based on the experience gained in the field of circuit-breakers

withmagneticdrive,ABBhasimplementedthistechnologyin

the field of contactors.

The magnetic drive adapts perfectly to this type of apparatus

thanks to its precise and linear travel.

This means that a simple and direct axial transmission of the

movement to the moving contacts of the vacuum interrupter

canberealised,withbothelectricalandmechanicalbenefits.

Thedrive,whichisofbistabletype,isfittedwithanopening

and a closing coil.

The two coils - individually energised - allow the drive core to

be moved from one of the two stable positions to the other.

The drive shaft is solid with an iron core which is immersed

and held in position in a field generated by two permanent

magnets(fig.A).

Energising the coil opposite to the magnetic latching position

(fig.A)ofthecore,themagneticfield(fig.B)isgenerated,

which attracts and moves the core into the opposite position

(fig.C).

Every opening and closing operation creates a magnetic

field concordant with the one generated by the permanent

magnets,withtheadvantage,duringservice,ofkeeping

the intensity of the field itself constant as the number of

operations carried out increases.

The energy needed for operation is not supplied directly

bytheauxiliarypowersupply,butisalways“stored”inthe

capacitorwhichactsasanenergyaccumulator,andtherefore

operationalwaystakesplacewithconstantspeedsandtimes,

regardless of the divergence of the power supply voltage from

the rated value.

NEPSI.COM - Northeast Power Systems. Inc.

Loading...

Loading...