Loading...

Loading...

Do you have a question about the Allen-Bradley 22C-D088A103 and is the answer not in the manual?

| Manufacturer | Allen-Bradley |

|---|---|

| Model Number | 22C-D088A103 |

| Category | Controller |

| Current Rating | 88A |

| Input Voltage | 120V AC |

| Memory | Not Applicable |

| Amperage | 88A |

| Voltage Rating | 480V |

| Number of Poles | 3 |

Key safety information, warnings, and hazard classifications for safe operation and handling.

Provides essential safety precautions for handling and installing the drive to prevent damage or injury.

Outlines essential factors for properly mounting the drive, including surface requirements and environmental factors.

Recommends appropriate fuses and circuit breakers for branch circuit protection and installation requirements.

Offers guidance on wiring the drive's input/output terminals, including control wiring and terminal block specifications.

Explains how to configure and control drive start, stop, direction, and speed from various sources.

Outlines instructions and requirements related to Electromagnetic Compatibility (EMC) and CE conformity.

Provides instructions and requirements for complying with FCC regulations regarding radio frequency emissions.

Outlines the essential steps and checks required before applying power to the drive.

Explains how to control basic drive functions like start, stop, direction, and speed.

Details the functions and operation of the drive's built-in integral keypad for control and programming.

Provides instructions on how to navigate and modify drive parameters using the integral keypad.

Explains the Hand-Off-Auto functionality of the keypad for controlling drive operation modes.

Describes how to switch between Local and Remote control modes for operating the drive.

Explains the Auto/Manual modes for controlling the drive's frequency and operation.

Outlines how parameters are organized into groups for efficient access and management.

Details commonly programmed parameters for essential drive configuration and operation.

Explains parameters related to terminal block functions, including digital and analog I/O.

Details advanced parameters for fine-tuning drive performance and features.

Introduces drive faults, categorizes them, and directs users to fault descriptions for troubleshooting.

Explains the auto restart feature for automatically resetting and restarting the drive after certain faults.

Lists common causes and corrective actions for when the motor fails to start.

Addresses issues where the drive does not react to changes in the speed command.

Explains troubleshooting steps when the motor or drive fails to reach the commanded speed.

Provides solutions for diagnosing and resolving unstable motor operation issues.

Offers guidance on troubleshooting issues related to the drive's inability to reverse motor direction.

Details steps to diagnose and fix issues where the drive fails to power up.

Provides recommended AC line input fuse and circuit breaker information for protection.

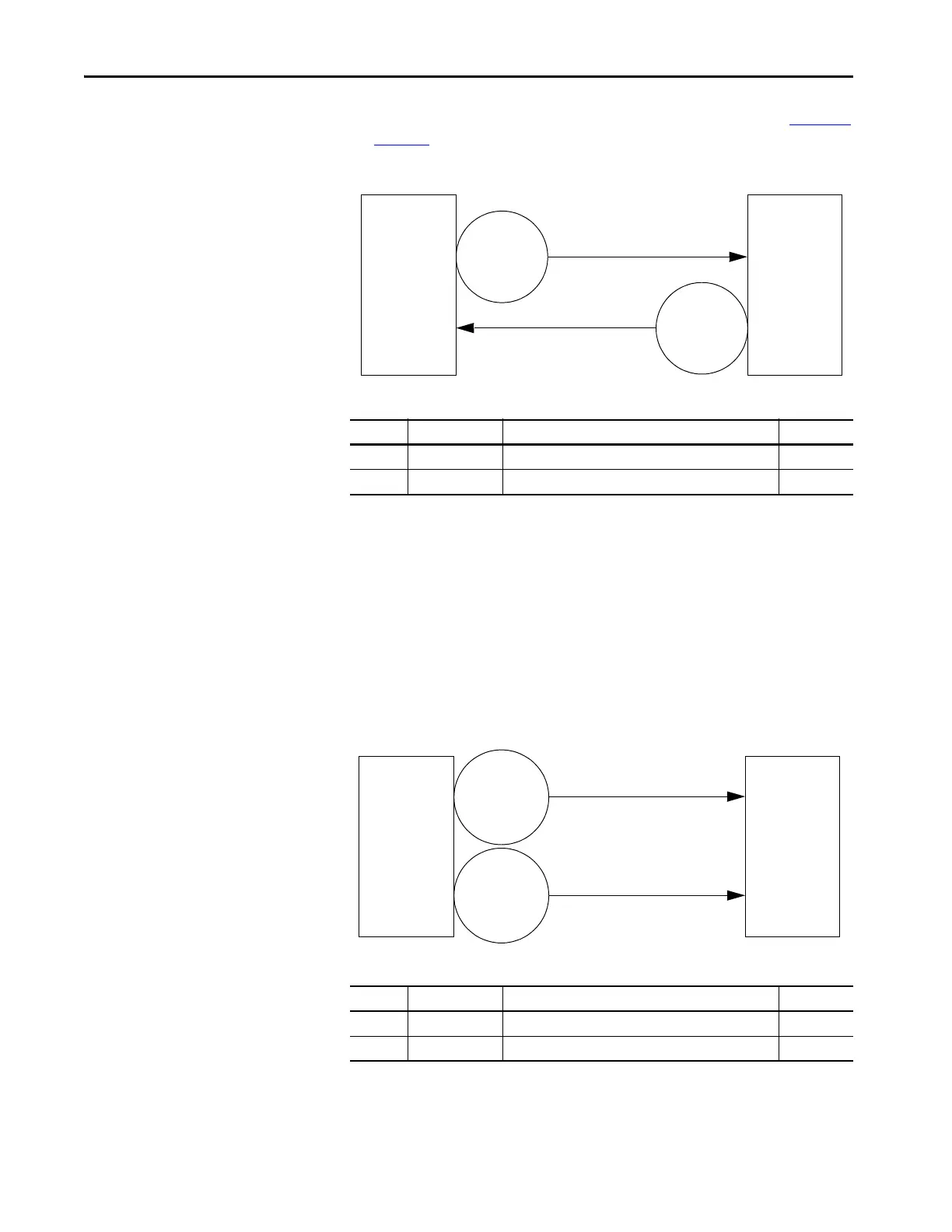

Provides essential guidelines for connecting peripherals using the RJ45 DSI Splitter Cable.

Introduces the drive's built-in PID control loop for process feedback and setpoint maintenance.

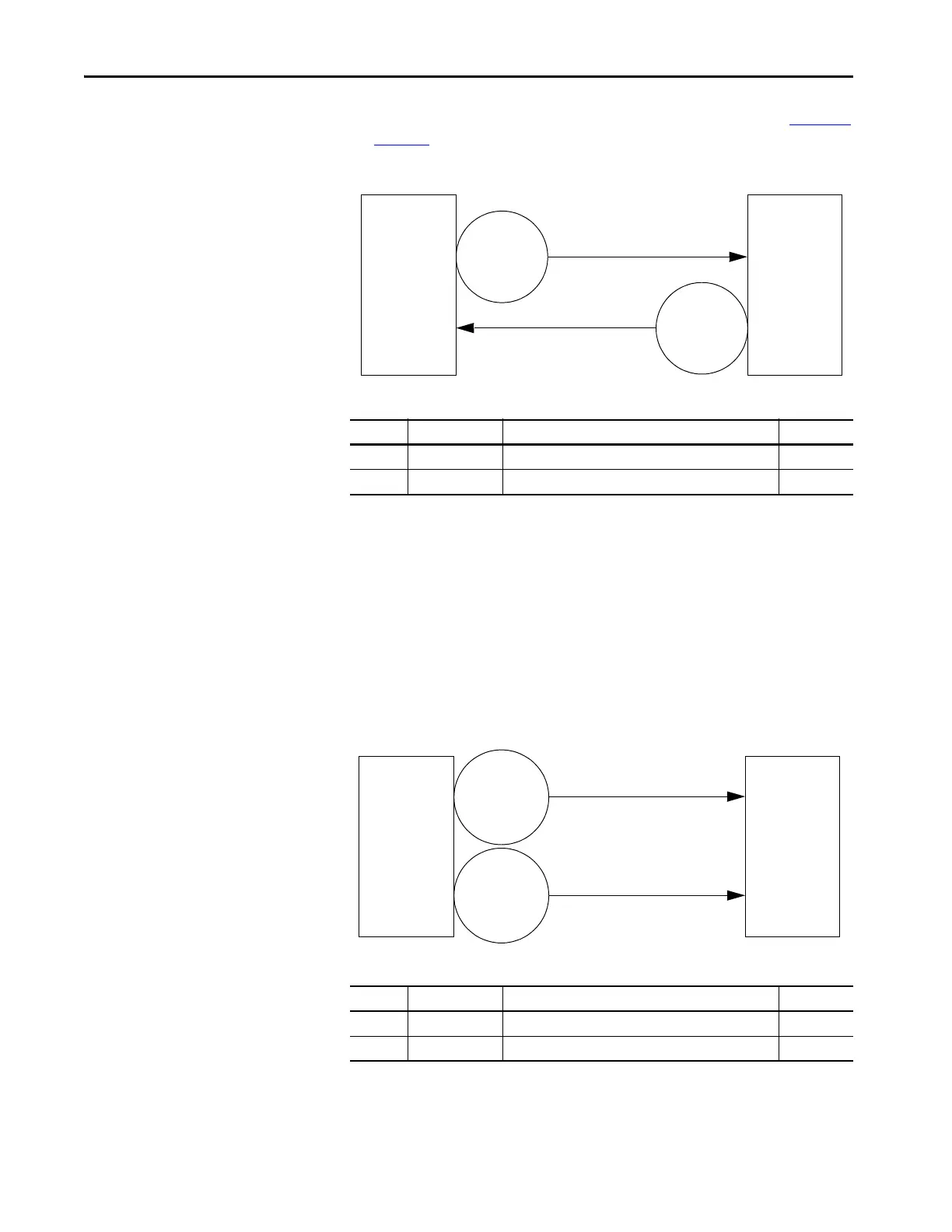

Details the feature for controlling up to three auxiliary motors alongside the main drive-controlled motor.