Rockwell Automation Publication 1606-RM008A-EN-P - November 2021 31

DC-UPS - 24V, 20 A, 480 W Reference Manual

precise battery charging and testing which results in the longest possible

battery life.

The battery module is available in two different options. It can be ordered with

assembled batteries (1606-XLSBATASSY4) or as a battery bracket without

batteries (1606-XLSBATBR4), allowing for different battery options. The

mounting bracket option also allows the batteries to be assembled just in time,

avoiding outdated batteries due to limited shelf life.

Application Notes Battery Replacement Intervals

There are two main causes for battery failures and the need for replacing them:

- Random failures: Within the defined service life of a battery, random battery

failures can happen. For example, short circuit in one cell, broken cell

connection, acid pollution, and mechanical defects. Such failures occur

randomly and cannot be predicted. The 1606-XLS480-UPS has various battery

test features included, which periodically test both batteries individually and

report such failures. These battery tests include:

• Battery presence test, performed every 10 s

• Battery dynamic impedance test, performed every 4 hours

• Charging time period (max 40 h in <10 Ah settings and max 170 h in

>10Ah settings) Battery tests start as soon as the batteries are fully

charged (the green status indicator must be on solid). Battery dynamic

impedance tests must fail several times in a row before “replace battery”

is reported. This can take up to 14 additional hours after the batteries are

fully charged.

- Wear-out failures: The electrical characteristics of batteries degrade slowly

over time. Main causes are chemical effects, which can be calculated.

Therefore, battery manufacturers specify the design life of batteries to be able

to calculate the expected service time. The degradation of a battery cannot be

easily tested on a running system. Therefore and the results from the battery

tests of the 1606-XLS480-UPS (random failures), a periodical replacement is

strictly recommended.

Service and design life of a battery:

Batteries have a limited service life and must be replaced periodically. The

service life depends on the grade of the battery, which is expressed in the

design life. The design life figures can be found in the individual data sheets of

the batteries and is specified according to the Eurobat guideline.

The design life is the estimated life, that is based on laboratory condition, and

is quoted at 20 °C using the manufacturer’s recommended float voltage

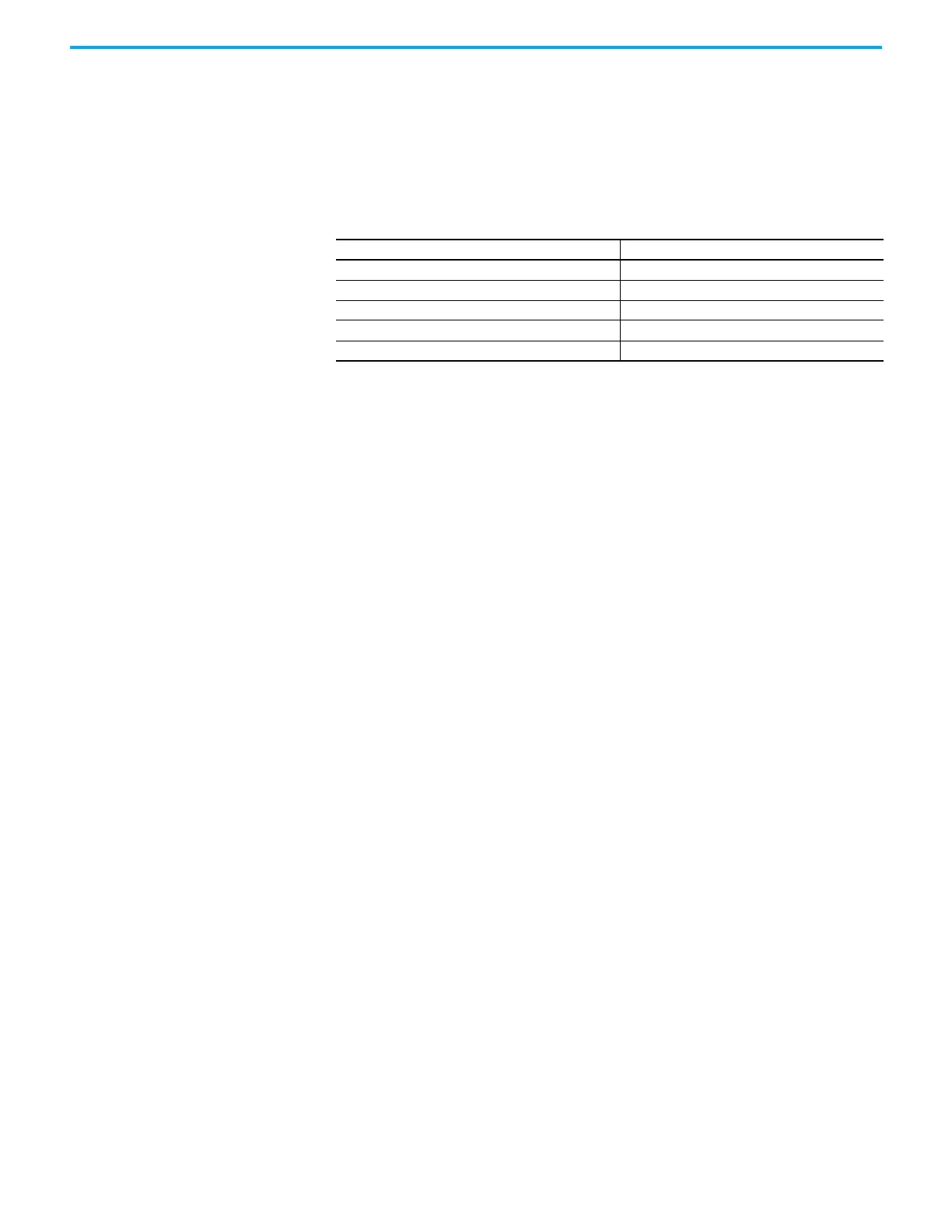

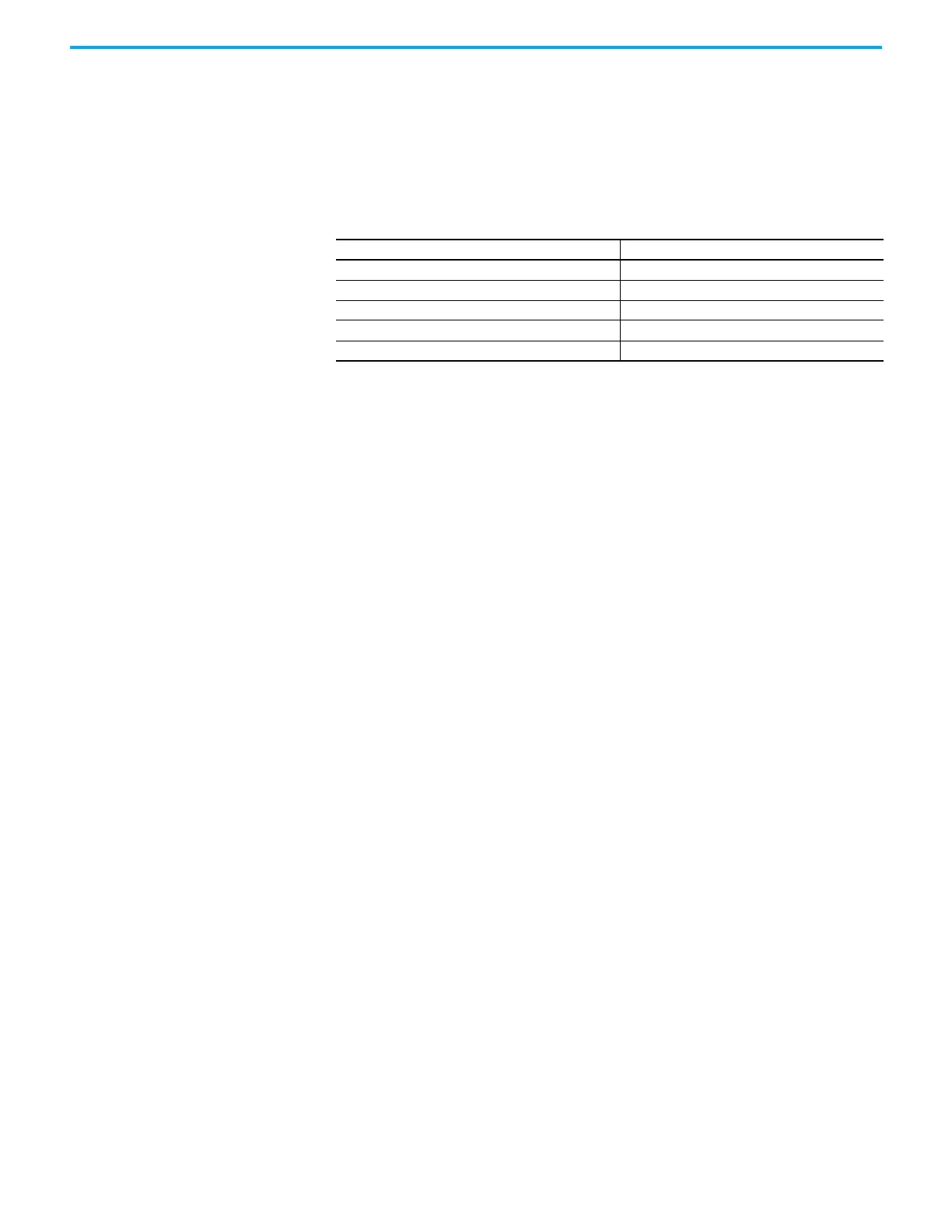

Attribute Value

Battery voltage DC 24V

Battery capacity 12 Ah

Temperature sensor PT1000

Dimensions WxHxD 203 x 186 x 143 mm (7.99 x 7.32 x 5.63 in.)

Weight 1606-XLSBATASSY4 / 1606-XLSBATBR4 9000 g / 900 g (19.84 lb / 1.98 lb)

Loading...

Loading...