12 MicroLogix 1200 Analog Output Module

Publication 1762-IN016B-EN-P - December 2005

Wire Size and Terminal Screw Torque

Each terminal accepts up to two wires with the following restrictions:

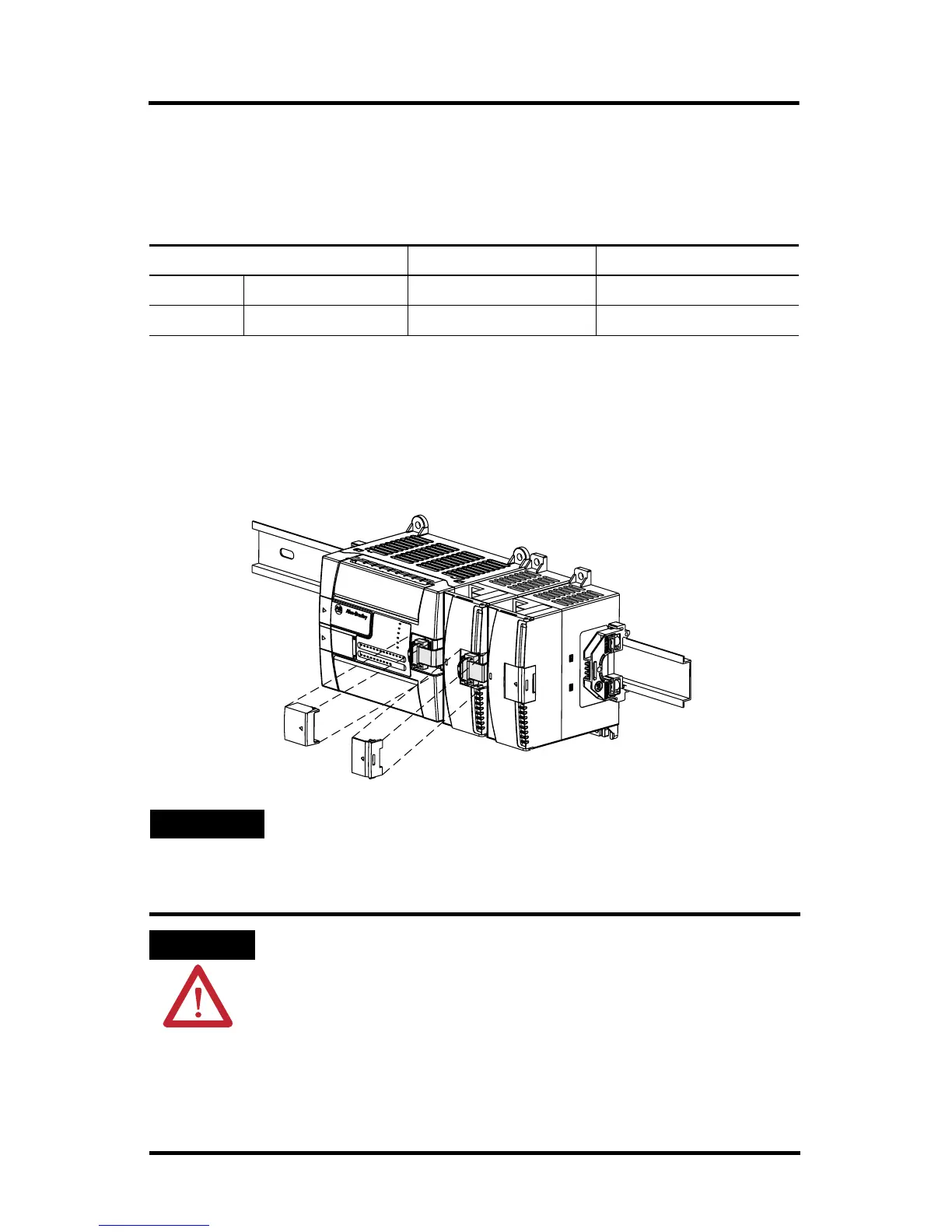

System Assembly

The expansion I/O module is attached to the controller or another I/O module by

means of a ribbon cable after mounting as shown below.

Figure 8 Ribbon Cable Connection

Wire Type Wire Size Terminal Screw Torque

Solid Cu-90 °C (194 °F) #14 to #22 AWG 0.904 Nm (8 in-lbs)

Stranded Cu-90 °C (194 °F) #16 to #22 AWG 0.904 Nm (8 in-lbs)

TIP

Use the pull loop on the connector to disconnect modules. Do

not pull on the ribbon cable.

ATTENTION

EXPLOSION HAZARD

• In Class I, Division 2 applications, the bus connector must be

fully seated and the bus connector cover must be snapped in

place.

• In Class I, Division 2 applications, all modules must be

mounted in direct contact with each other as shown on

page 7. If DIN rail mounting is used, an end stop must be

installed ahead of the controller and after the last 1762 I/O

module.

Loading...

Loading...