ON

OFF

1

2

5

6

l

FR

Dans le cas d’une dureté de l ’eau

supérieure à 20 °f, prévoir un traitement de

’eau.

NL

Bij waterhardheid van meer dan 20

°f, een water verzachter voorzien.

DE

Wenn

der Härtegrad des Wasser über 11°dH (20 °f)

beträgt, ist eine Wasserenthärtung

vorzusehe

n.

IT

Se l’acqua ha una durezza

superiore a 20 °f, prevedere un dispositivo di

trattamento.

ES

En el caso de que la dureza

del agua sea superior a 20 °f, prever un

tratamiento del agua.

PT

Nos casos em que a

dureza da água seja superior a 20 °f, prever

um sistema de tratamento de água.

UK

If the

water hardness is more than 20 °f, install a

water softener.

CZ

V prípade, ze tvrdost vody

presahuje 20 °f, je treba aplikovat vhodnou

úpravnu vody.

HU

Ha a víz keménysége

nagyobb, mint 20°f német keménységi fok,

akkor a víz kezelésér l gondoskodni

kell.

PL

twar

wody jest w

nale

y zainstal

ow

owiednie ur

zenie.

20 °f su sertli

ini geçen sular için su

ıtma tavsiye edilmelidir (su arıtma

teriye aittir).

RO

Daca apa are o duritate

are dacat 20 °f, este necesara tratarea in

l a acesteia.

RU

.

XXXX

xxxxx

xxxxx

xxx

XXXX

xxx

MIN

Q

G30 - G31 28/37 mbar

1009942-05

5

4

2

1

3

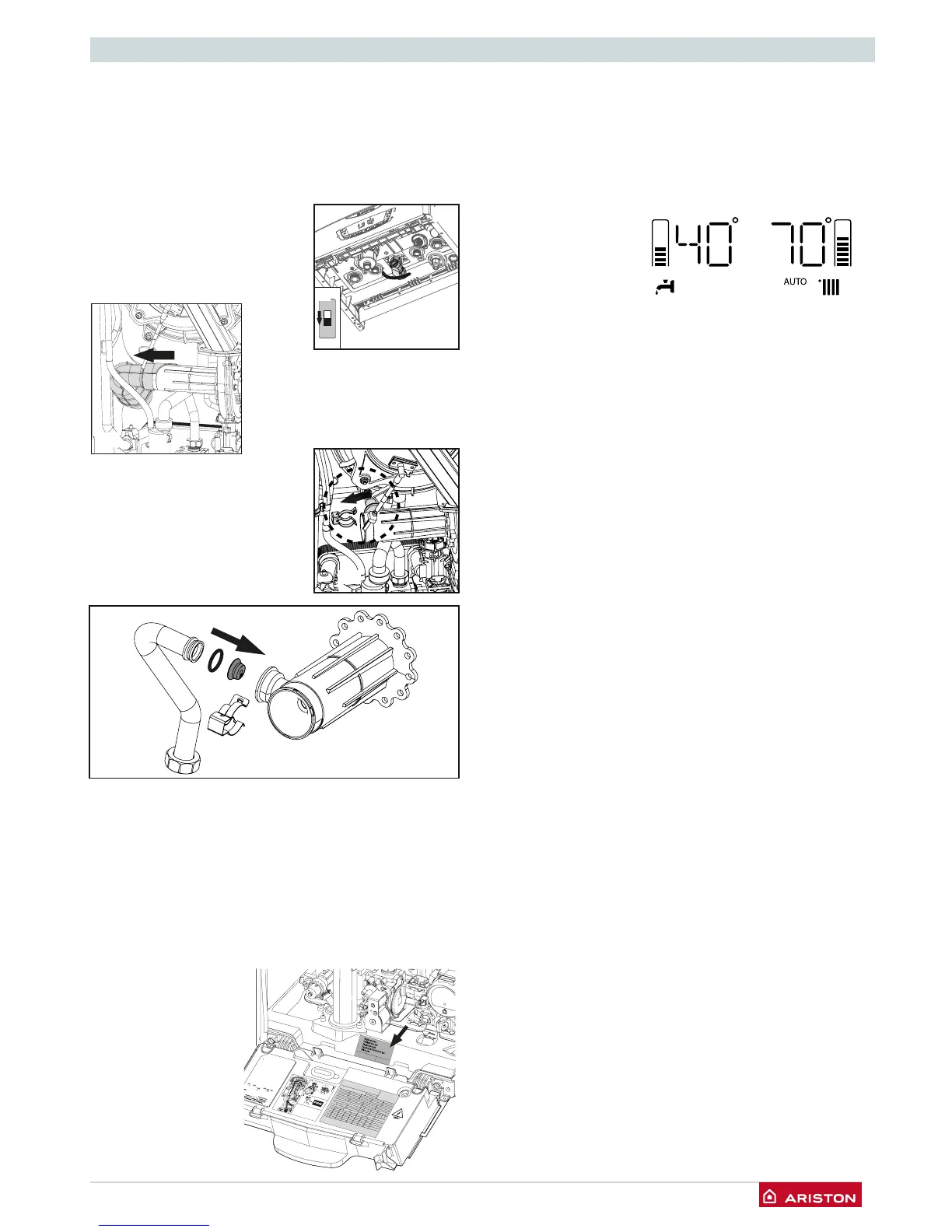

Converting the appliance from Natural gas to LPG

These appliances are designed to operate with different gas

types.

The appliance must only be converted for use with a different

gas type by a Gas Safe Registered installer.

To convert the appliance to LPG:

(use these instructions in conjunction with the Instruction sheet

supplied with the LPG Kit).

1.

Electrically isolate the appliance (g 1)

2. Turn off the gas supply (g 2)

3. Remove the outer case, lower the

front control panel.

4. Remove the silencer (g 3)

5. Disconnect the gas supply from

the venturi assembly (g 4)

6. Inset the correct diaphragm

(depending on the output of the

appliance) into the venturi spigot

(g 5)

7. Reassemble the gas supply onto the venture assembly (g 4)

and reattach the silencer.

8. Turn on gas supply and test for tightness

9. Purge gas supply

10. Turn the electrical supply on to the appliance.

11. Commission the appliance, check the working pressure is

adequate then test and adjust the CO² values at maximum

and minimum output described in the commissioning section

of the appliance installation instructions. Ensure the ue

gas analyser used is calibrated and set for the gas group

the appliance is being

adjusted for.

12. Check the appliance

for gas leaks using

gas leak detection

uid.

13. Afx the label to

the appliance that

is supplied with the

conversion kit.

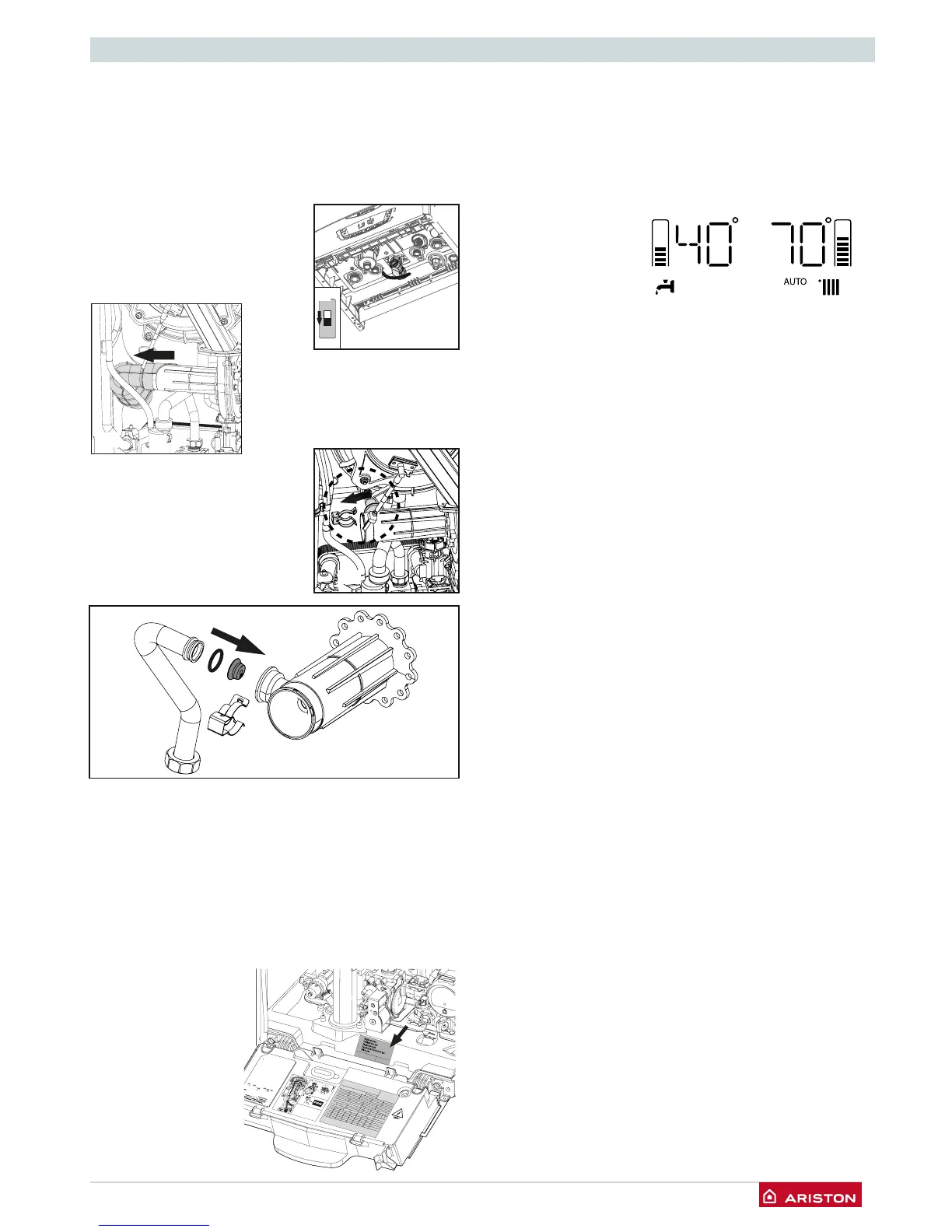

AUTO function

This is a function which enables the boiler to automatically

adapt its operation routine (the temperature of the heating

elements) in line with the outdoor conditions, in order to achieve

and maintain the requested room temperature conditions.

Depending on the peripheral units connected and the number

of zones controlled, the boiler adjusts its ow temperature

automatically.

The various

corresponding

parameters should

therefore be set (see

adjustments menu).

To activate the function,

press the

button.

Example 1:

Single zone system (high-temperature) with on/off room

Thermostat:

In this case the following parameters must be set:

4 21 - Activation of temperature adjustment using sensors

- Select 1 = Basic temperature adjustment

2 44 - Boost Time (optional)

The wait time for the ow temperature increase in steps of

4°C may be set. The value varies according to the type of

system and installation.

If the Boost Time value = 00 the function is not activated.

Example 2:

Single zone system (high-temperature) with on/off room

Thermostat + outdoor sensor:

In this case the following parameters must be set:

4 21 - Activation of temperature adjustment using sensors

- Select 3 = outdoor sensor only

4 22 - Temperature adjustment curve selection

- Select the relevant curve according to the type of

system, installation, heat insulation used in the building,

etc.

4 23 - Perform a parallel curve shift if necessary, increasing

or decreasing the set-point temperature (this may also

be modied by the user, using the heating temperature

adjustment knob, which, with the Auto function activated,

is used to shift the curve in a parallel manner).

Example 3:

Single zone system (high-temperature) with Sensys controller +

outdoor sensor

In this case the following parameters must be set:

4 21 - Activation of temperature adjustment using sensors

- select 4 = outdoor sensor + room sensor

4 22 - Temperature adjustment curve selection

- Select the relevant curve according to the type of

system, installation, heat insulation used in the building,

etc

4 23 - Perform a parallel curve shift if necessary, increasing or

decreasing the set-point temperature. (This may also be

changed by the user by the buttons 8 which, with the

Auto function activated, is used to shift the curve in a

parallel manner.)

4 24 - Inuence of room sensor

- used to adjust the inuence the room temperature has

on the calculation of the set-point ow temperature (20 =

maximum, 0 = minimum).

Note: See page 40 for details on accessing menus.

Loading...

Loading...