◆

Check the working tool, make sure that it is

sharp and not worn out. Check that the tool

shank is clean.

◆

Replace worn components in good time.

In order to ensure that the machine remains within

the stated vibration level values, the following

checks must be performed:

Wear check

If a working tool with a worn shank is used,

machine vibration will increase. Avoid such

vibration by checking for shank wear before

mounting the working tool on the machine.

◆

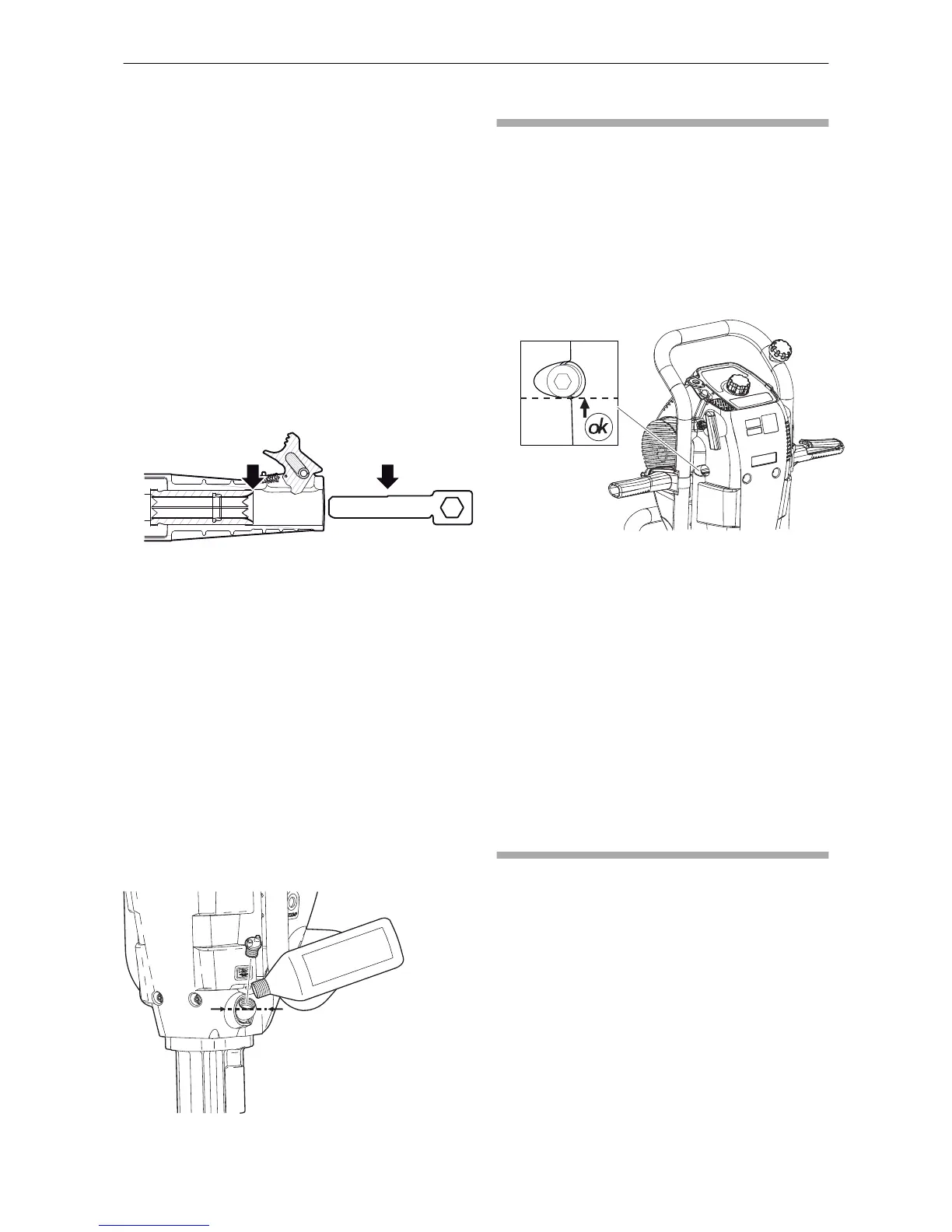

Use the shank gauge that corresponds to the

dimension of the working tools shank. If the

gauge can be inserted beyond point A in the

tool chuck (point B) then the tool chuck must be

replaced immediately.

Air filter check

A clogged air filter will eventually cause damage to

the engine. Check the air filter regularly.

1. Unscrew the air filter cover.

2. If the air filter is dirty, it must be replaced.

Never wash the air filter.

3. Clean filter container.

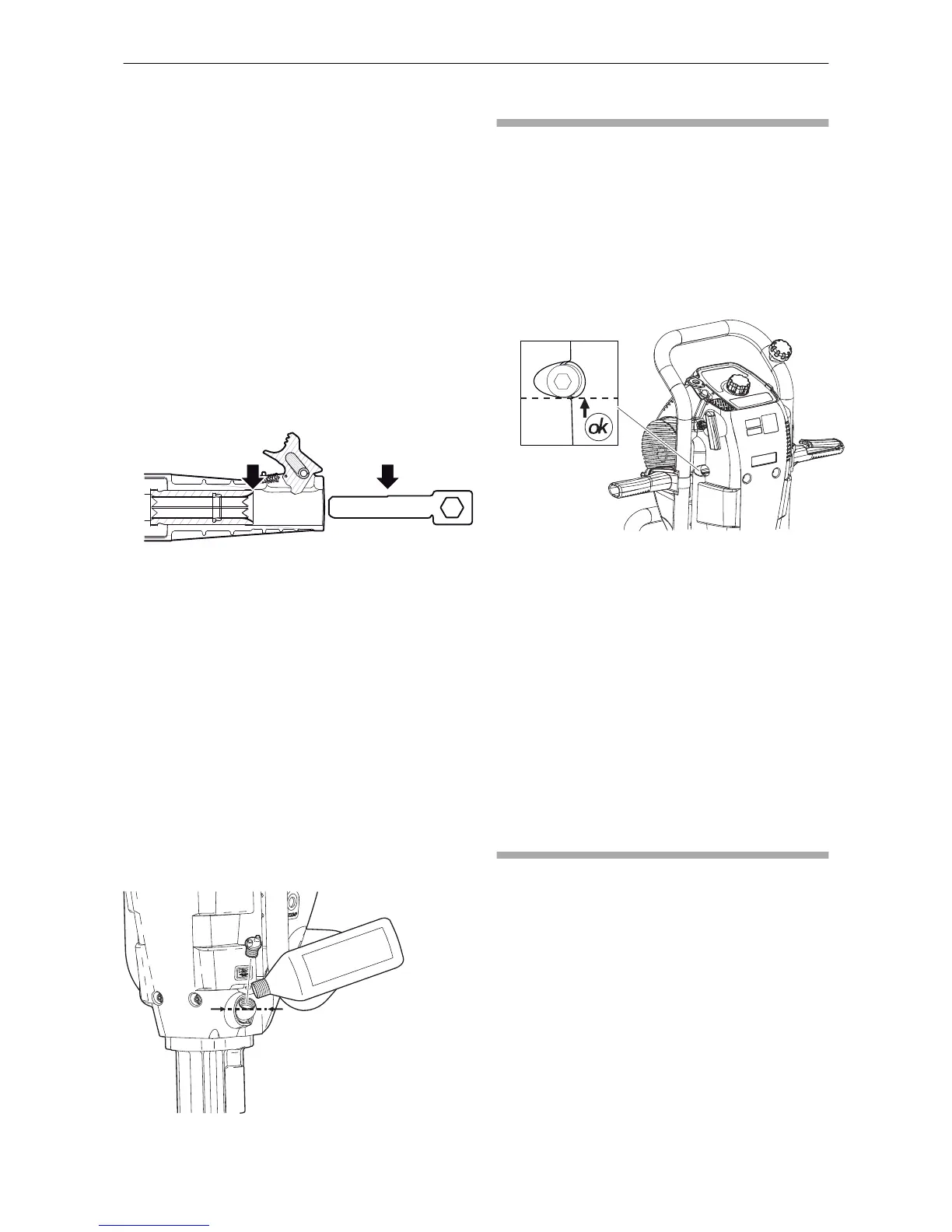

Hammer mechanism oil check

The machine has a natural oil consumption and

the oil level in the impact unit should be checked

every day. The machine must be upright when

performing the oil check. The oil level must be at

the same height as the filling pipe. When filling,

check that the sealing is undamaged and tighten

properly.

Use only Atlas Copco IMPACT-OIL.

Every month

Gearbox oil level check

1. The level in the gearbox is checked by

unscrewing the oil plug using the spark plug

wrench.

2. Fill the oil using an oil can to avoid spilling. The

oil level is correct when it reaches the lower

edge of the filling hole when the machine is

standing upright. The volume of the gearbox is

0.1 litre. Use only Atlas Copco IMPACT-OIL.

3. When finished filling, screw back the oil plug

with a torque of 2 Nm.

Spark plug check

If the spark plug electrodes are very dirty or

burned, replace the spark plug. The spark plug is

placed under the service cover, mounted in the

cylinder head. See the section "Main parts" for

position of the spark plug.

Only use Champion RCJ8 and make sure that the

electrode gap is 0.6-0.7 mm (0.024-0.028 in.)

before fitting the spark plug. Tighten the spark plug

using the correct tightening torque, see Spare

parts list.

Service

The machine indicates when service is needed by

means of the top cover LED service indicator. With

continuous use of operation, leave the machine for

service according to the following service interval:

•

Every 150 hours of operation (6 months)

Service must for safety reasons be performed by

authorised personnel at an authorised workshop.

Also, only authorised personnel are allowed to

connect to the machine's ECU and, furthermore,

after each service it is adviceable to check the

speed (r.p.m) and make a simple check of the

vibration levels of the machine. The service kits

needed can be found in the Spare parts list.

COBRA PROi Safety and operating instructions

© Construction Tools PC AB | 9800 1758 01 | 2017-01-10

Original instructions

17

Loading...

Loading...