Roto Synthetic Fluid ULTRA

Roto Synthetic Fluid ULTRA is a synthetic oil based 4000 hours lubricant, specially developed

for use in single stage oil injected screw compressors running in demanding conditions. Roto

Synthetic Fluid ULTRA can be used for compressors operating at ambient temperatures between

0 ˚C (32 ˚F) and 40 ˚C (104 ˚F). For more extreme conditions, or when continuously operating at

temperatures above 40 °C (104 °F), it is recommended to use Roto Synthetic Fluid XTEND

DUTY.

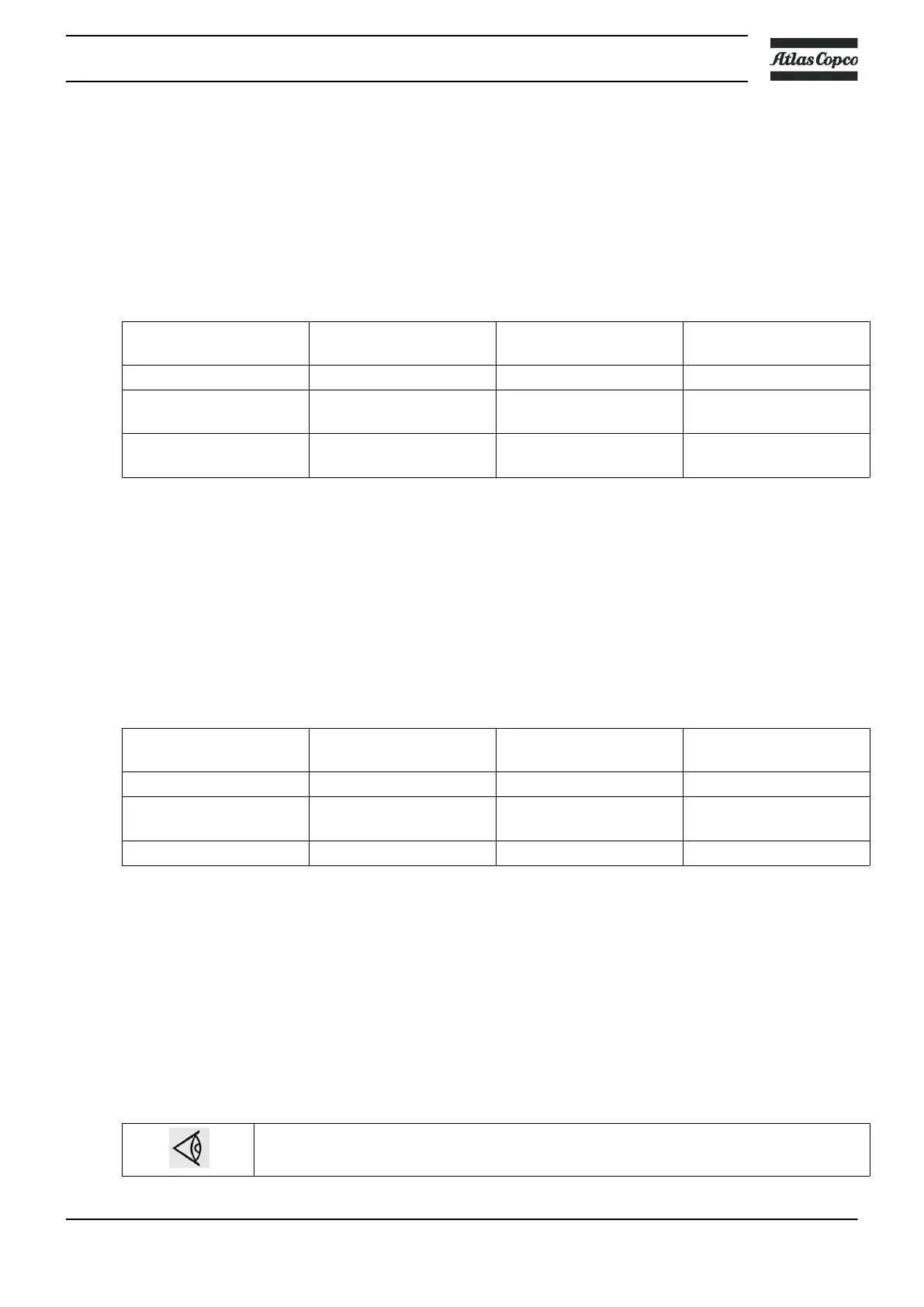

See the table bloew for recommended oil exchange intervals:

Ambient temperature Element outlet

temperature

Exchange interval Maximum time interval

up to 35°C (95°F) up to 100°C (212°F) 6000 2years

from 35°C (95°F) up to

40°C (104°F) (see note)

from 100°C (212°F) up to

105°C (221°F)

4000 2years

from 40°C (104°F) up to

45°C (113°F) (see note)

from 105°C (221°F) up to

110°C (230°F)

2000 2years

Note: the presence of dust and/or high humidity may require a shorter exchange interval. Consult

Atlas Copco.

Roto Synthetic Fluid XTEND DUTY

Atlas Copco's Roto Synthetic Fluid XTEND DUTY is a high quality synthetic 8000 hours

lubricant for oil injected screw compressors which keeps the compressor in excellent condition.

Because of its excellent oxidation stability, Roto Synthetic Fluid XTEND DUTY can be used for

compressors operating at ambient temperatures between 0 ˚C (32 ˚F) and 46 ˚C (115 ˚F).

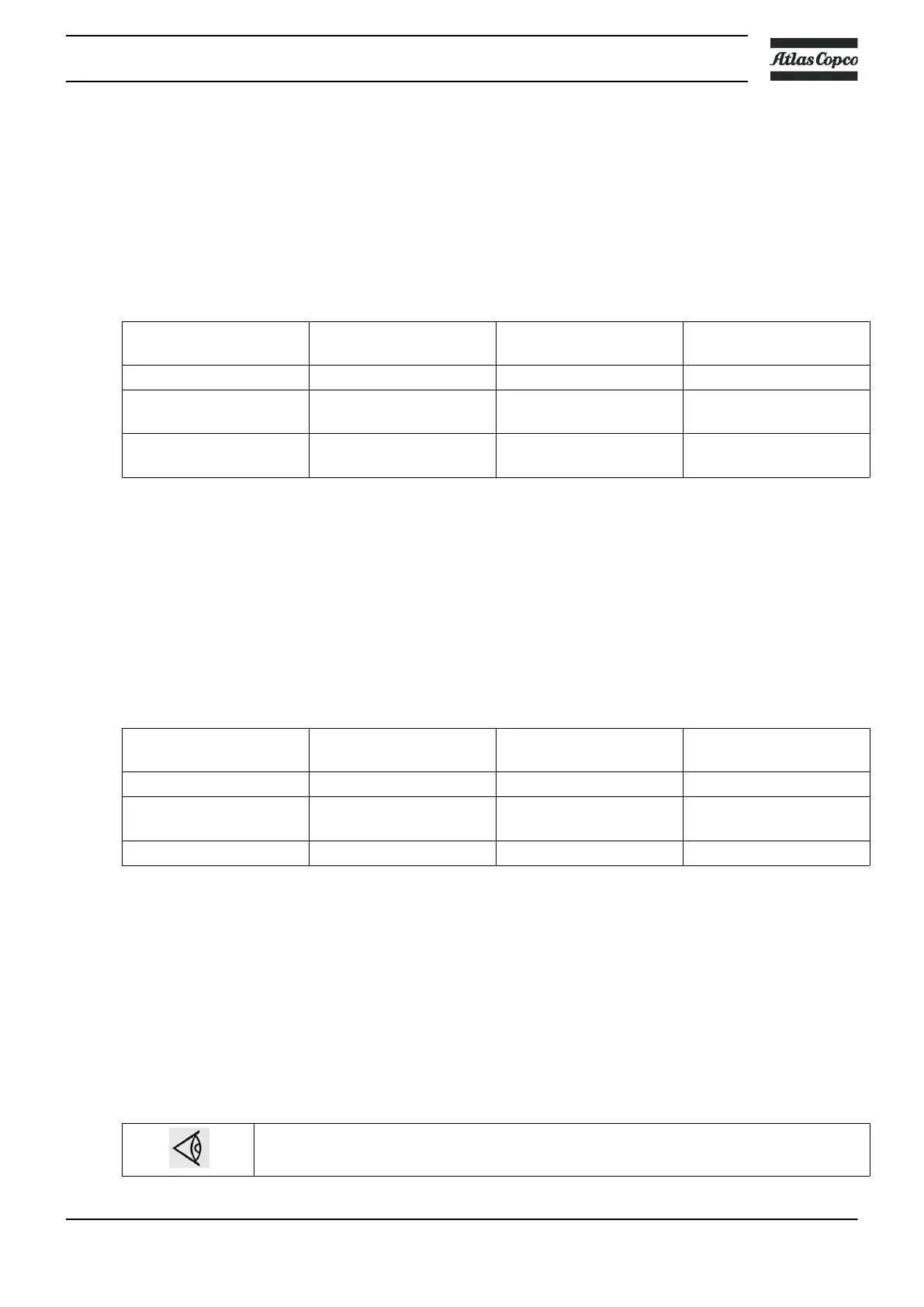

See the table below for oil exchange intervals:

Ambient temperature Element outlet

temperature

Exchange interval Maximum time interval

up to 35°C (95°F) up to 100°C (212°F) 8000 2 years

from 35°C (95°F) up to

40°C (104°F) (see note)

from 100°C (212°F) up to

105°C (221°F)

6000 2 years

above 40°C (104°F) above 105°C (221°F) 5000 2 years

Note: the presence of dust and/or high humidity may require a shorter exchange interval. Consult

Atlas Copco.

* Whichever comes first.

6.3 Storage after installation

Procedure

Run the compressor regularly, e.g. twice a week, until warm.

If the compressor is going to be stored without running from time to time, protective

measures must be taken. Consult Atlas Copco.

Instruction book

API161475 65

Loading...

Loading...