29

EN

table 2

CO2 min

METHANE GAS

(G20)

LPG

(G31)

25C 9,0 10,0 %

30C

9,0 10,0 %

Make sure the ue gas temperature value, read in info I008 (see “5.3

INFO menu ”), is coherent (with a tolerance ± 5°C) with the value

measured by the analyser.

After completing the check:

quit the function by pressing

056

.

rpm

reposition the previously removed components

set the boiler to the required operating mode, depending on the

season

regulate the heat request temperature values according to the custo-

mer’s needs.

b

When the combustion analysis function is active, all heat requests

are inhibited and the message “CO” appears on the display.

IMPORTANT

The combustion analysis function is active for max. 15 minutes; the bur-

ner shuts down if a delivery temperature of 95°C is reached. It will ignite

again when the temperature falls below 75°C.

b

The combustion analysis function is usually carried out with the

3-way valve on heating. The 3-way valve can be switched to DHW

by generating a DHW request at the maximum output while the

function itself is still active. In this case, the DHW temperature will

be limited to a maximum value of 65°C. Wait for the burner to fire

.

4.9 Adjustments

The boiler has already been adjusted by the manufacturer. If the adjust-

ments need to be made again however e.g. following extraordinary

maintenance, after the replacement of the gas valve, after conversion

from methane gas to LPG or vice versa, or after a new regulation for

inside-chimney pipes, follow the procedures described below.

The adjustment of the maximum and minimum output, maximum heating

and slow ignition must be made in the sequence indicated, and by qua-

lified personnel only:

power up the boiler

set the parameters

306 minimum fan speed

307 maximum fan speed

308 slow ignition

309 maximum fan speed for heating

313 ignition speed in restart

table 3

MAX. NO. FAN

ROTATIONS

METHANE GAS

(G20)

LPG

(G31)

25C: CH - DHW 7.000 - 8.700 6.900 - 8.500 rpm

30C: CH - DHW 6.900 - 8.300 6.800 - 7.900 rpm

4.10

table 4

MIN. NO. FAN

ROTATIONS

METHANE GAS

(G20)

LPG

(G31)

25C

1.500 2.050 rpm

30C

1.500 1.700 rpm

table 5

NO. FAN ROTATIONS

SLOW IGNITION

METHANE GAS

(G20)

LPG

(G31)

25C - 30C 5.500 5.500 rpm

Gas valve calibration

Run the CO2 check procedure as explained in paragraph

“4.8

Combustion analysis”.

If the values need to be modified, proceed as

follows

:

check the CO2 adjustment values with the casing closed

remove the casing as explained in paragraph “3.7 Removing the casing”

check the CO2 adjustment values again, with the casing open

on the basis of the difference in values with the casing closed and

open, if necessary bring the CO2 to the value shown in the table (1

and 2) - (minus) the difference found. Example

:

CO2 value measured with the casing closed

= 8,5%

CO2 value measured with the casing open

= 8,3%

value to be set for CO2 with the casing open

= 8,8%

value to be set for CO2 with the casing closed

= 9,0%

to adjust the CO2 value

:

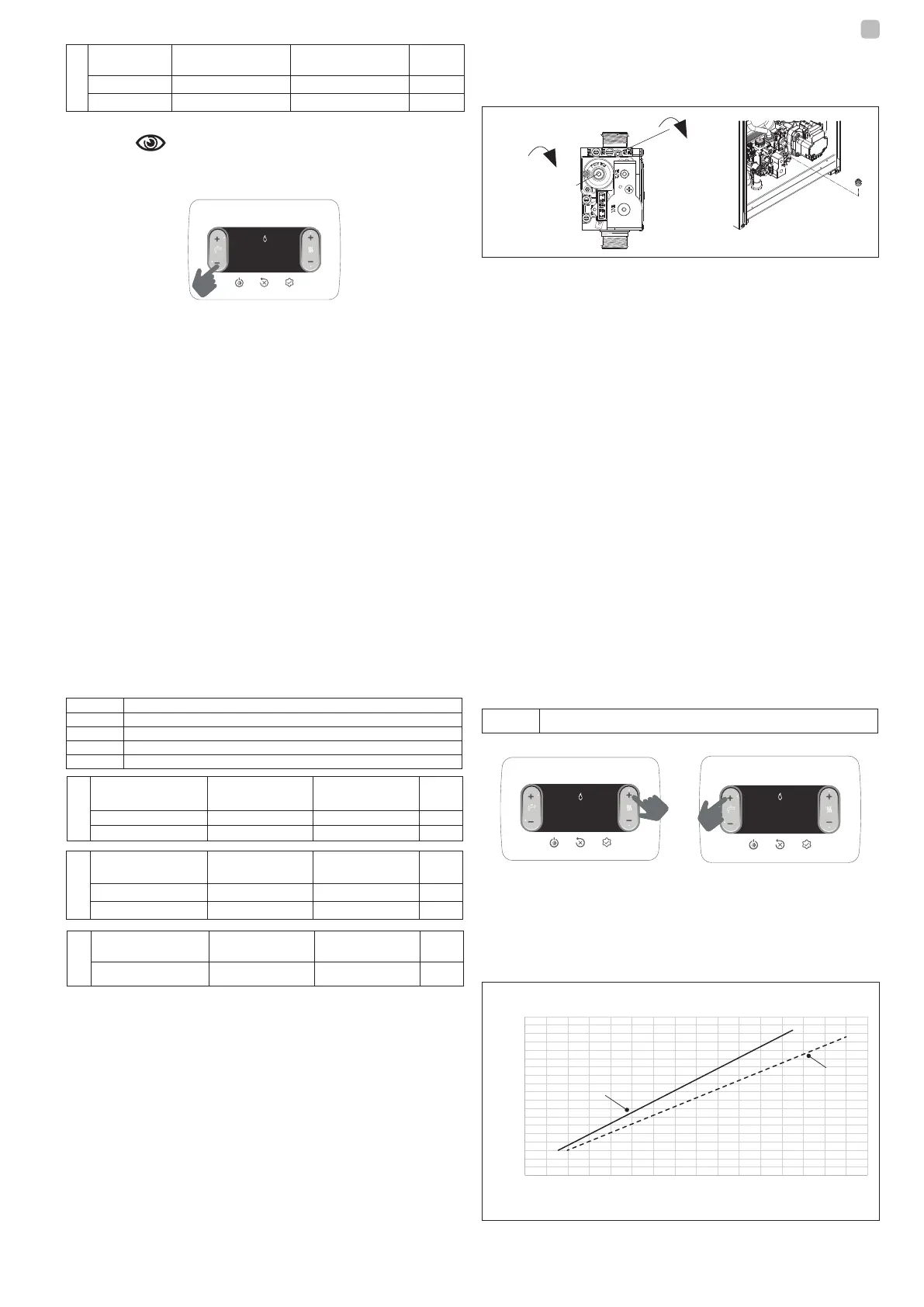

rotate the max. power adjustment screw clockwise to reduce the

value, or anti-clockwise to increase it

rotate the min. power adjustment screw clockwise to increase the

value, or anti-clockwise to reduce it

with the casing open and after adjusting the CO2 value at the mini-

mum power, check the adjustment of the CO2 at the maximum power

again

after completing the adjustments, replace the casing and check the

CO2 corresponds to the value shown in the table 1 and 2

.

CO2 -

CO

2 +

Minimum output

adjustment

screw

Maximum output

adjustment screw

4.11 Gas conversion

Conversion from the gas of one family to the gas of another family can be

done easily even when the boiler is already installed.

This operation must be carried out by professionally qualified personnel.

The boiler is designed to operate with methane gas (G20) or LPG (G31)

according to the product label. The boiler can be transformed to LPG or

to methane gas (G20) by means of special kits.

For disassembly refer to instructions below:

disconnect the boiler from the electricity supply and turn off the gas tap

remove the casing as explained in paragraph “3.7 Removing the casing”

release the instrument panel and rotate it forwards

unscrew the ramp nut from the gas valve and rotate the ramp so as to

have access to the gas nozzle (B) in the outlet fitting

remove the nozzle (B) and replace it with the one from the kit

put the ramp of the gas valve back in place and screw the nut

reposition the previously removed components

power up the boiler and open the gas tap again.

Adjust the boiler as explained in paragraphs “4.9 Adjustments” and “4.10

Gas valve calibration”.

b

Conversion must be carried out by qualified personnel

b

After the transformation, apply the new gas rating plate inclu-

ded in the kit.

b

After each intervention on the adjustment element of the gas

valve, seal it with sealing varnish.

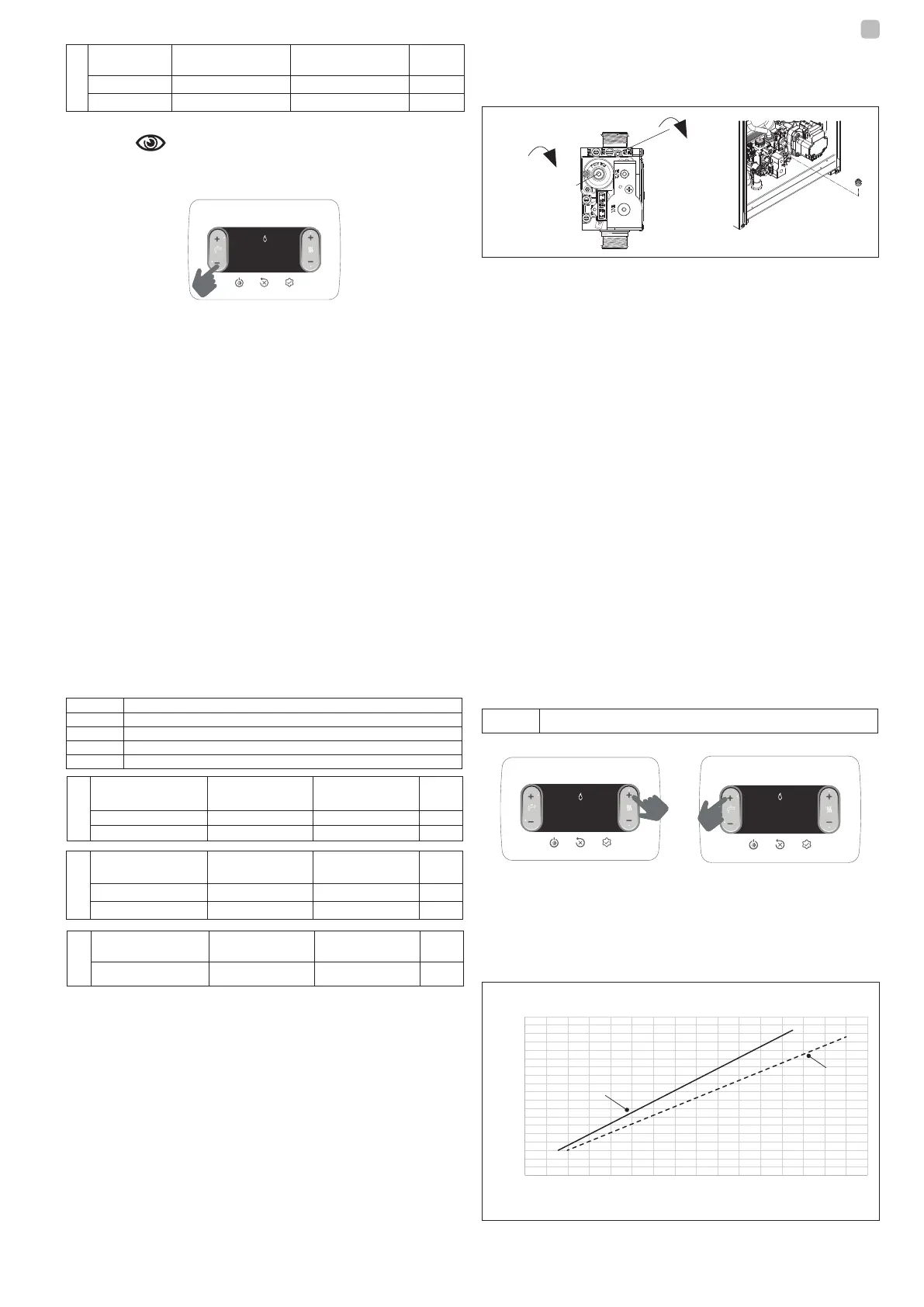

4.12 Range rated

This boiler can be adapted to the heating requirements of the system,

in fact it is possible to set the maximum delivery for heating operation of

the boiler itself:

power up the boiler

set the parameter

310 Range rated

Set the maximum heating value (rpm) and confirm.

confirm

MAX

rpm

007

.

rpm

007

.

rpm

Record the new set value in the table on the back cover of this manual.

For subsequent controls and adjustments, refer to the set value.

b

The calibration does not entail the ignition of the boiler.

The boiler is supplied with the adjustments shown in the technical data

table. Depending on plant engineering requirements or regional flue gas

emission limits however, this value can be modified by referring to the

graph below.

0

500

1000

1500

2000

2500

3000

3500

4000

4500

5000

5500

6000

6500

7000

7500

8000

8500

9000

9500

0 2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 32

25C

30C

Fan rotation (r.p.m.)

Heat input (kW)

Heat input curve - fan rotation

Loading...

Loading...