(Fig. 7)

(Fig. 8)

14 15

Setting of potentiometer zero is achieved thanks to the «0% postion» screw.

Drive the actuator to the closed position.

Resistance value is measured between terminals 16 and 17.

Hold the pinion located just under the plate with the «0% position»

marking while driving the potentiometer screw. Adjust the potentiometer

so that the resistance value exceeds 0 Ohm and regularly increases then

turn backwards to reach a value as close to 0 Ohm as possible.

Mettre le servomoteur en position ouverte et noter la valeur de résistance

pour le 100%. Revenir en position fermée et vérifier que la valeur du 0%

est bien répétable et proche de 0 Ohm.

Drive the actuator to the open position and write down the resistance

value corresponding to the 100% position.

Come back to the closed position and check that, for the 0% position,

the resistance shows a close to zero repeatable value.

Note: If actuator is equipped with 2 potentiometers, each potentiometer is

set independently of the other.

Signal inversion:

To inverse the signal variation direction, invert potentiometer wires

on the actuator terminal board (e.g. for a connection on 16/17/18, invert

16 and 18).

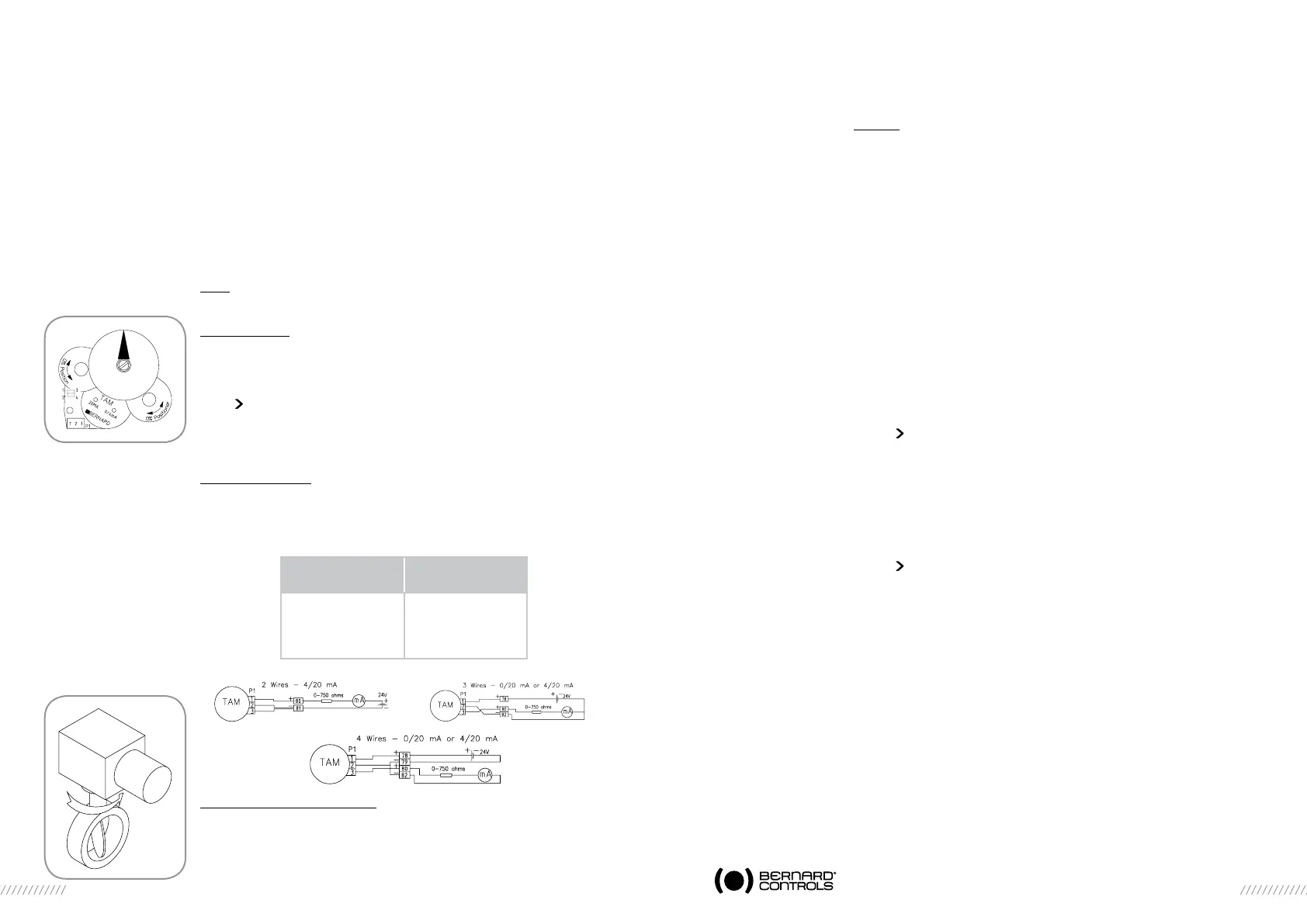

9 «TAM» FEEDBACK POSITION TRANSMITTER (OPTION - Fig.7)

The TAM transmitter delivers a 0/4 to 20 mA signal linearly proportional

to the valve position.

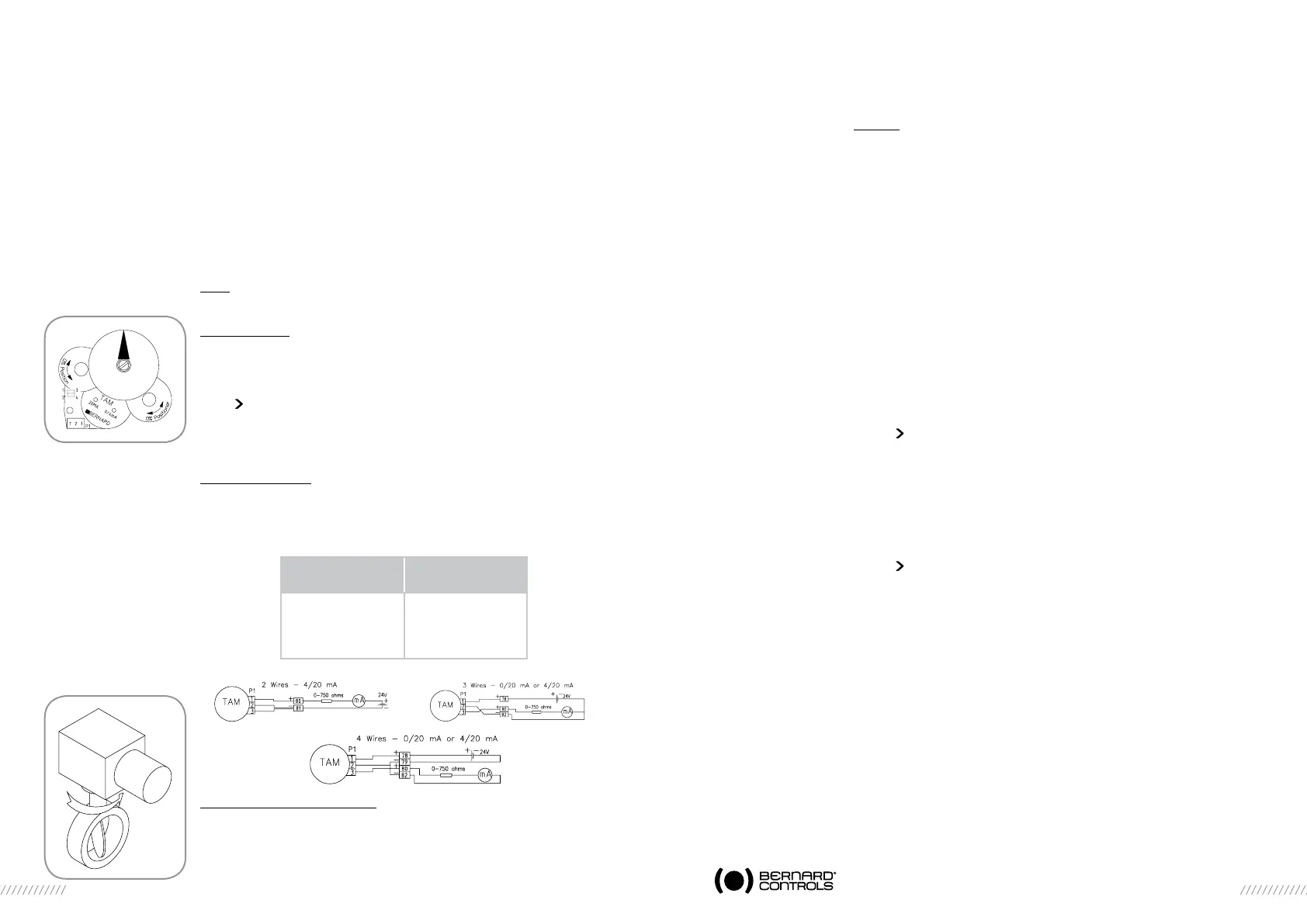

Electric connections

Refer to the actuator standard wiring diagram. See also some typical

wiring examples below. FIltered or stabilised power supply should be provided

within the 12 to 32 VDC range. Maximum admissible ohmic load values

are given in the table :

Signal direction inversion (Fig.8)

The TAM transmitter, when supplied with a standard actuator, provides

a signal that rise from close position to open position, the standard opening

direction being counter-clockwise.

If an opposite signal variation is required, simply move 2 jumpers on the board

near the potentiometer.

Direct signal: jumpers on 1-3 and 2-4

Reversed signal: jumpers on 1-2 and 3-4

Settings

Connect a milliampermeter at the place of burden.

- Always start by adjusting the 0/4mA.

- Drive actuator to the position corresponding to the 0/4 mA (closed

in standard),

- Hold the pinion located just under the plate with the «0% position»

marking while driving the potentiometer screw. Adjust the potentiometer

so that the output current reaches a minimum value. Turn backwards

until the current value regularly increases then turn backwards again

and stop as soon as the minimum value determined here above

has been reached. The potentiometer is then positioned at the very

beginning of its track.

- Then, use the TAM adjustment screw marked as «0/4mA» to adjust

the current to a value as close to the 0/4 mA as possible.

- Drive actuator to the position corresponding to the 20 mA (open

in standard),

- Turn the screw marked «20mA» in order to read exactly 20 mA

on the milliampermeter.

- Come back to the closed position and check that, for the 0% position,

the signal current shows a close to 0/4 mA and repeatable value.

10 PRÉCAUTIONS

Close the cover immediately after start-up and make sure that the cover

seals are not damaged and remain clean.

It is important to ensure a proper protection covers closing in order

to avoid any water entry.

In case of water entry, dry thoroughly and check electric insulation before

replacing covers.

11 MAINTENANCE AND STORAGE INSTRUCTIONS

Maintenance

All ST actuators are lubricated for lifetime and therefore require no specific

maintenance.

The condition of the valve stem and its nut must nevertheless be checked

periodically to make sure they are clean and well lubricated.

We recommend that a program of periodic maintenance should be drawn

up for actuators that are operated unfrequently.

Storage

The actuator includes electric equipment as well as grease lubricated gear

stages. In spite of the weatherproof enclosure, oxidation, jamming and

other alterations are possible if actuator is not correctly stored.

The actuators should therefore be stored under a shelter in a clean, dry

place and protected from wide changes in temperature.

Avoid placing the actuators directly on the floor. For the actuators equip-

ped with a heating resistance, it is recommended that to connect and

power supply it especially if the storage area is humid (standard voltage

230 volts, unless otherwise specified).

Power Supply DC

(VOLT)

Max. admissible

load Ohm

12 150

34 750

30 1050

Loading...

Loading...