Subject to change without prior notice Revised 05-12

6 720 220 045

14

CP/BP Series

concern regarding the quality of the well water

available or should any known hazards exist in your

area, we recommend proper testing to assure the

well water quality is suitable for use with water

source equipment. In conditions anticipating

moderate scale formation or in brackish water, a

cupro-nickel heat exchanger is recommended. In

well water applications water pressure must always

be maintained in the heat exchanger. This can be

accomplished with either control valve or a bladder

type expansion tank.

When well water is used exclusively for supplying water

to the heat pump, the pump should operate only when

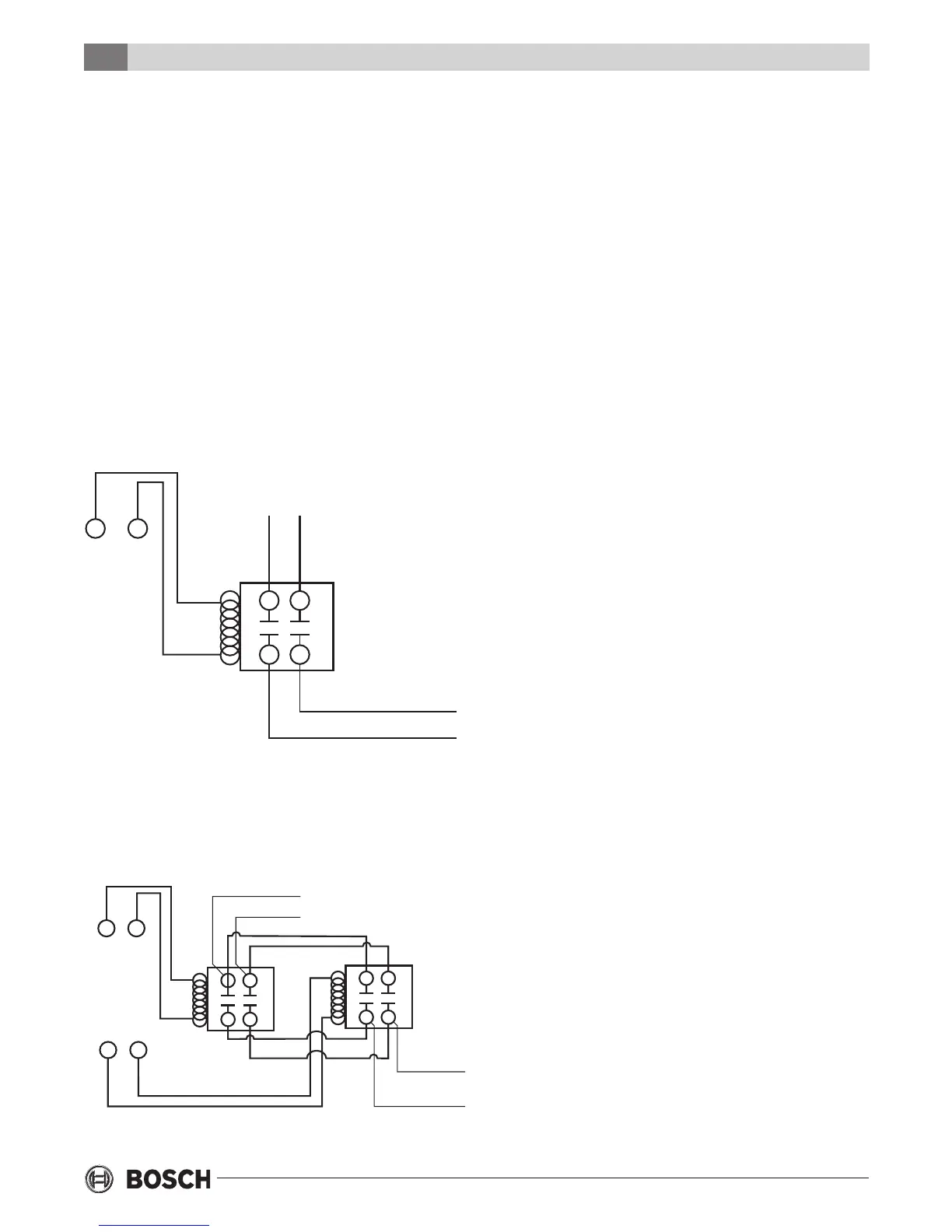

the heat pump operates. A 24 volt double pole-single

throw (DP/ST) contactor (Figure #6) can be used to

operate the well pump with the heat pump.

POWER SUPPLY

C Y1

UNIT

TERMINAL

STRIP

(24VAC)

POWER TO PUMP

DP/ST RELAY

Y1

Figure #6

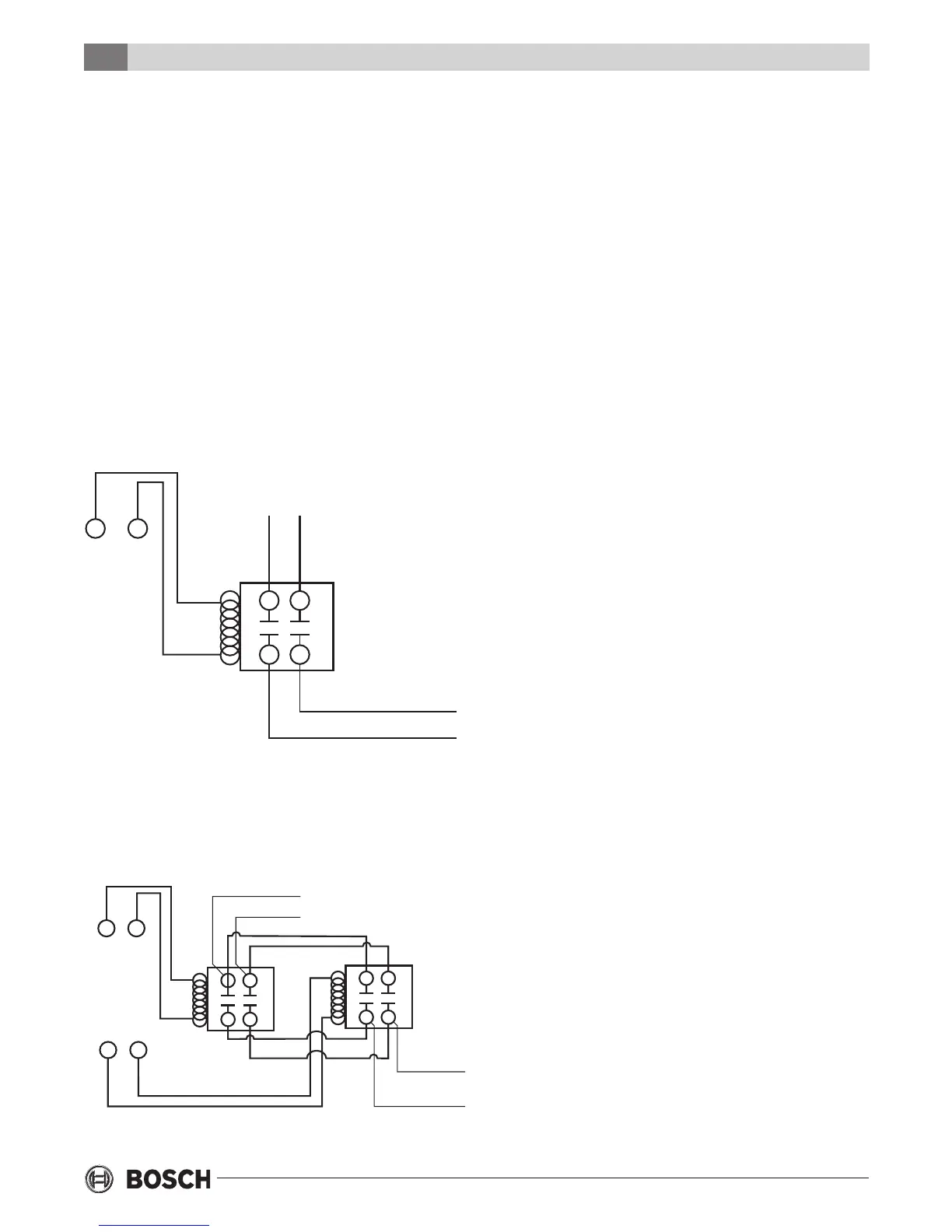

When two or more units are supplied from one well,

the pump can be wired (Figure #7) to operate

independently from either unit. An upsized VA

transformer may be required in either case.

Y1

Y1

POWER

TO PUMP

C

2 DP/ST

RELAYS

POWER SUPPLY

UNIT

TERMINAL

STRIP

(24VAC)

C

Figure #7

Pressure/temperature ports are recommended in

both the supply and return lines for system ow

balancing. The water ow can be accurately set by

measuring the water-to-refrigerant heat exchangers

water side pressure drop. See the unit specication

sheets for the water ow and pressure drop

information in the back of this manual.

The discharge water from the heat pump is not

contaminated in any manner and can be disposed

of in various ways depending on local codes (i.e.

discharge well, dry well, storm sewer, drain eld,

stream, pond, etc.)

When using a single water well to supply both

domestic water and the heat pump care must be taken

to insure that the well can provide sufcient ow for

both. In well water applications a slow closing

solenoid valve must be used to prevent water hammer.

Solenoid valves should be connected across Y and

C on the interface board for all. Make sure that the

VA draw of the valve does not exceed the contact

rating of the thermostat.

FRESH WATER SYSTEMS

The Units shall be designed to operate throughout the

range of entering uid temperature of 50°F to 110°F in

the cooling mode and 50°F to 80°F in the heating

mode. Units shall have an operating range of 25 °F to

80°F in the heating mode when equipped with the

optional extended range. In the cooling mode, heat is

rejected from the Bosch unit into the water loop. A

cooling tower provides evaporative cooling to the loop

water thus maintaining a constant supply temperature

to the unit. When utilizing open cooling towers,

chemical water treatment is mandatory to ensure the

water is free from corrosive elements.

A secondary heat exchanger (plate frame) between

the unit and the open cooling tower may also be

used. It is imperative that all air be eliminated from

the closed loop side of the heat exchanger to insure

against fouling.

In the heating mode, heat is absorbed from the

water loop. A boiler can be utilized to maintain the

loop at the desired temperature.

Fresh Water Systems

Loading...

Loading...