6 720 220 045

Revised 05-12 Subject to change without prior notice

7

CP/BP Series

capacity to handle the air required for the unit

application. If the duct system is too small, larger

ductwork should be installed. Check for existing

leaks and repair as necessary to ensure a tight air

seal within duct. The duct system and all diffusers

should be sized to handle the designed air ow

quietly. To maximize sound attenuation of the unit

blower, the supply and return air plenums should

be insulated. There should be no direct straight air

path thru the return air grille into the heat pump.

The return air inlet to the heat pump must have at

least one 90 degree turn away from the space

return air grille. If air noise or excessive air ow are

a problem, the blower speed can be changed to a

lower speed to reduce air ow. (Refer to ECM

motor speeds and settings in Table #1)

Always disconnect power to the unit before

changing motor speed to prevent damage to

the motor, injury or death due to electrical

shock.

ELECTRICAL

Always disconnect power to the unit before

servicing to prevent injury or death due to

electrical shock or contact with moving parts.

All eld wiring must comply with local and national

re, safety and electrical codes. Power to the unit

must be within the operating voltage range

indicated on the unit’s nameplate. On three phase

units, phases must be balanced within 2%.

Operating the unit with improper line voltage

or with excessive phase imbalance is

hazardous to the unit and constitutes abuse

and is not covered under warranty.

Properly sized fuses or HACR circuit breakers must

be installed for branch circuit protection. See

equipment rating plates for proper size.

The heat pump units are provided with a concentric

knock-out in the front right corner post for

attaching common trade sizes of conduit. Route

power supply wiring through this opening. Flexible

wiring and conduit should be used to isolate

vibration and noise from the building structure. Be

certain to connect the ground lead to the ground

lug in the control box. Connect the power leads as

indicated on the unit wiring diagrams.

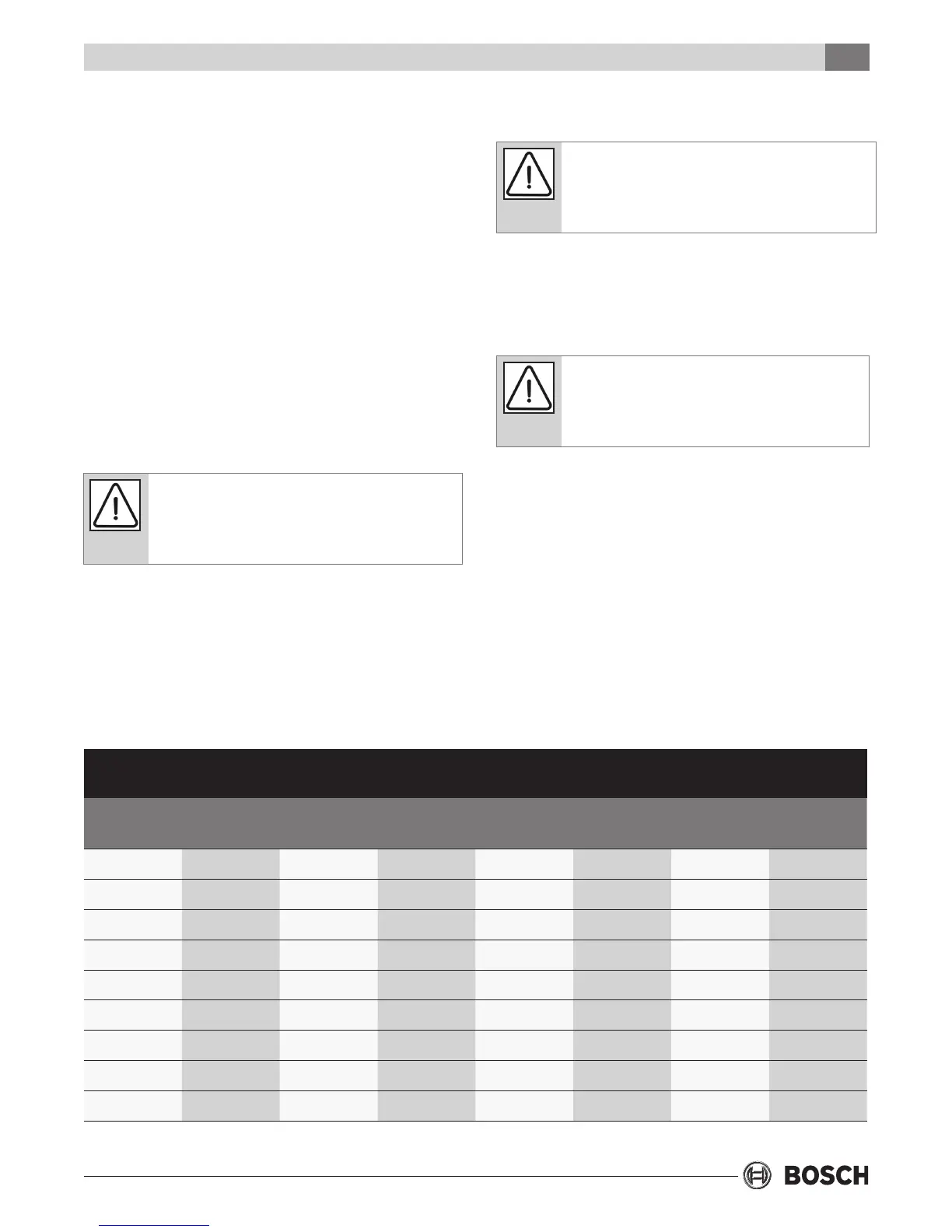

Table 1: CP/BP Motor CFM Selection (ECM Motor)otor Only)

Units

Motor Part

Number

Motor HP Tap1 Tap2 Tap3 Tap4 Tap5

CP/BP015 450-153 1/3 LOW MED HIGH - -

CP/BP018 450-153 1/3 - LOW - MED HIGH

CP/BP024 450-157 1/3 LOW MED HIGH - -

CP/BP030 450-154 1/3 LOW MED HIGH - -

CP/BP036 450-158 3/4 LOW MED HIGH - -

CP/BP042 450-155 3/4 LOW MED HIGH - -

CP/BP048 450-155 3/4 - LOW MED HIGH -

CP/BP060 450-156 1 LOW MED HIGH - -

CP/BP070 450-156 1 LOW - - MED HIGH

Electrical

Loading...

Loading...