Loading...

Loading...

Do you have a question about the Bosch EHP 6-11 LW and is the answer not in the manual?

Accessing frequently used settings for users.

How to increase or decrease heating by adjusting the curve slope.

Procedure for adjusting heat curve in cold conditions.

Setting heating schedules based on time and day.

Correctly setting the internal clock and date for proper function.

Accessing and viewing logged alarms and their status.

How to interpret and acknowledge alarm messages on the display.

Location and function of fuses and reset buttons for troubleshooting.

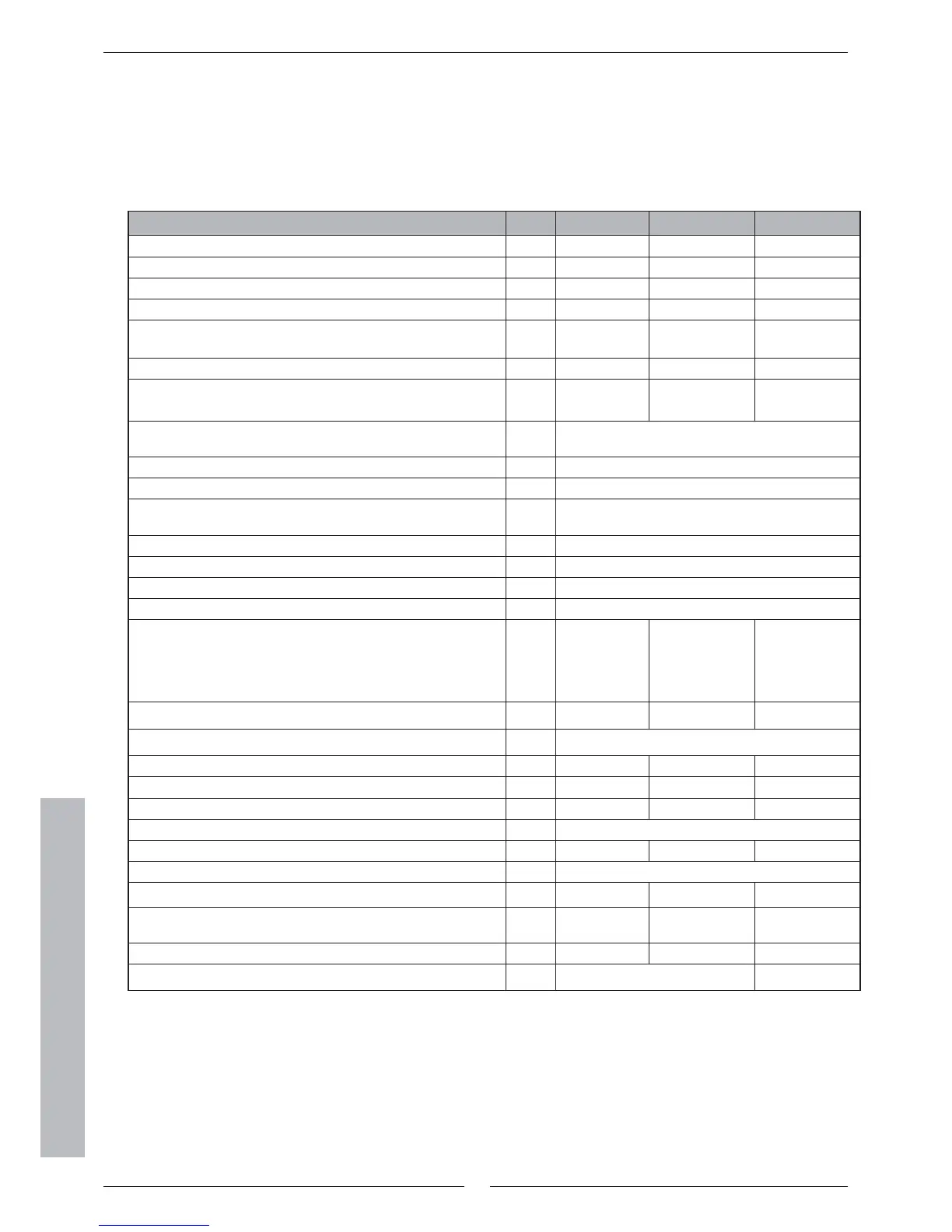

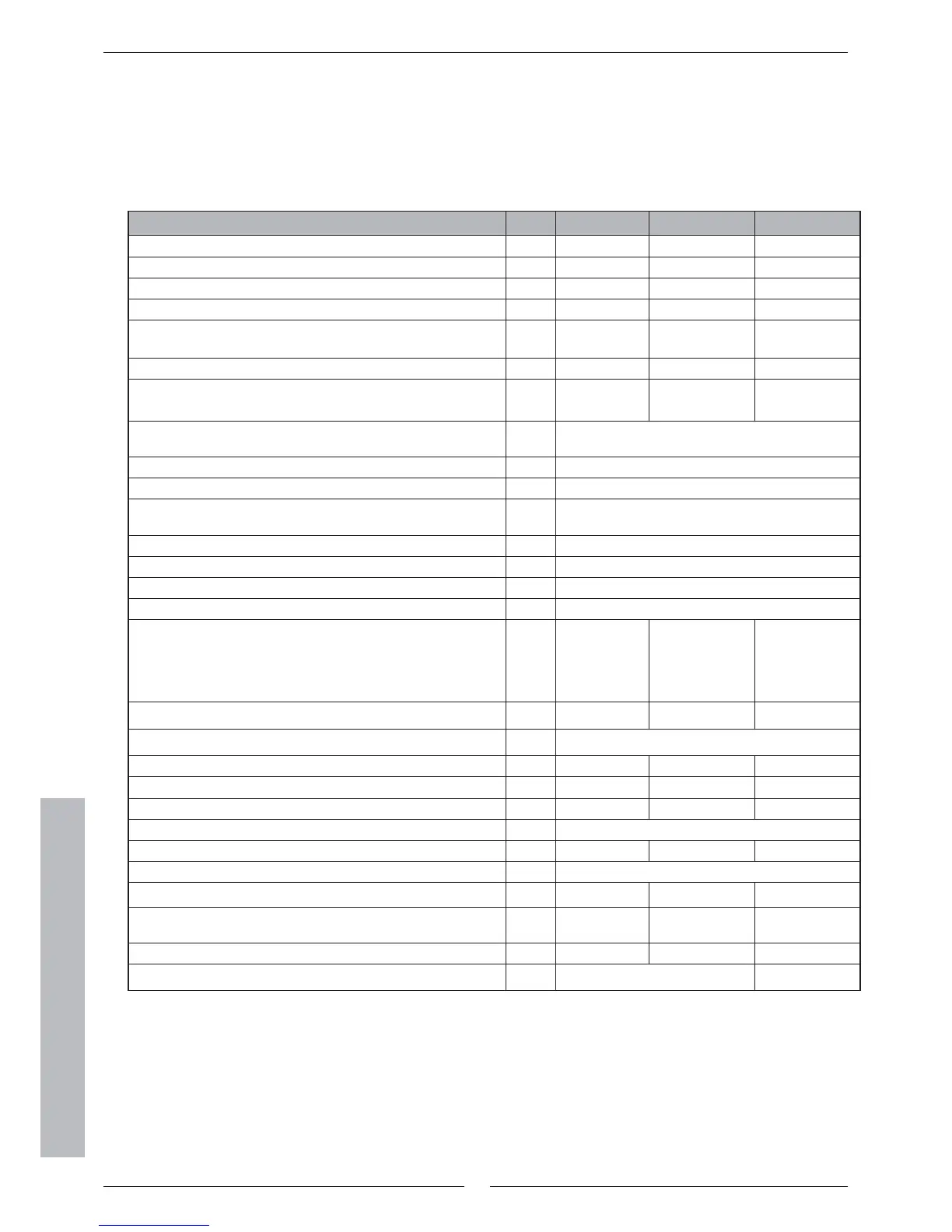

A list of all possible alarms and their corresponding causes.

Troubleshooting steps for compressor motor cut-out alarms.

Troubleshooting steps for HTF pump motor cut-out alarms.

Addressing alarms related to compressor overheating.

Troubleshooting low pressure switch alarms.

Troubleshooting high pressure switch alarms.

Addressing alarms related to the electric cassette.

Actions for power failure and incorrect phase alarms.

Troubleshooting alarms for high temperature difference in heat transfer fluid.

Addressing alarms for excessively high return water temperature.

Troubleshooting alarms for maximum heat transfer fluid output temperature.

General troubleshooting for defective sensors.

Addressing alarms for low heat transfer fluid temperature limits.

A step-by-step guide for installers to follow during installation.

General advice on connecting to the heating system, including flushing.

Details for connecting 3-phase and 1-phase power supplies.

Wiring for external sensors and mixing valves.

How to enter the service menu by holding the menu button.

Example of using the control panel for installer settings.

Initial startup procedure and checks.

Essential checks for pressure, levels, and temperature differences post-startup.

Resetting settings to factory defaults for installer or user levels.

Essential checks for pressure, levels, and temperature differences post-startup.