eF Series Heater

Installation Check List

Product Handling

- Carefully uncrate the heater. Move in place with a hand truck (Do not use

the venting pipes for handles).

Electrical Requirements

- Make sure there is 120 volts line voltage. Line voltage must be

properly polarized. Adequate ground supplied to the heater.

Venting Requirements

- All venting must stay within the required lengths and diameter (see

table below). Proper support of the venting pipe is a MUST (every 5ft vertical and 3ft horizontal).

Termination must be located to prevent re-circulation of flue gases. Medium to log sweep 90°

elbows are recommended.

Gas Requirements

- Gas piping sized adequately, ¾" or larger to heater. Install a properly sized

regulator (if unknown, assure an adequate volume of gas is available). 7" W.C. is required when the

unit is running. Gas pressure must stay below 14" W.C. static pressure. Pressure drops between

static pressure and operating flow should be less than 3" W.C.

Condensate Requirements

- Condensate line needs to slope to a drain at a minimum of ¼"

per foot. Make sure the condensate line does not have the potential to freeze. If using more than

one heater and using a common condensate line, make sure the condensate line is properly sized.

Service/Mechanical Room

- Provide adequate space for servicing heater. Leave room to get

to the top and bottom pressure switches as well as enough overhead room to remove the anode

rods for servicing (18" min.).

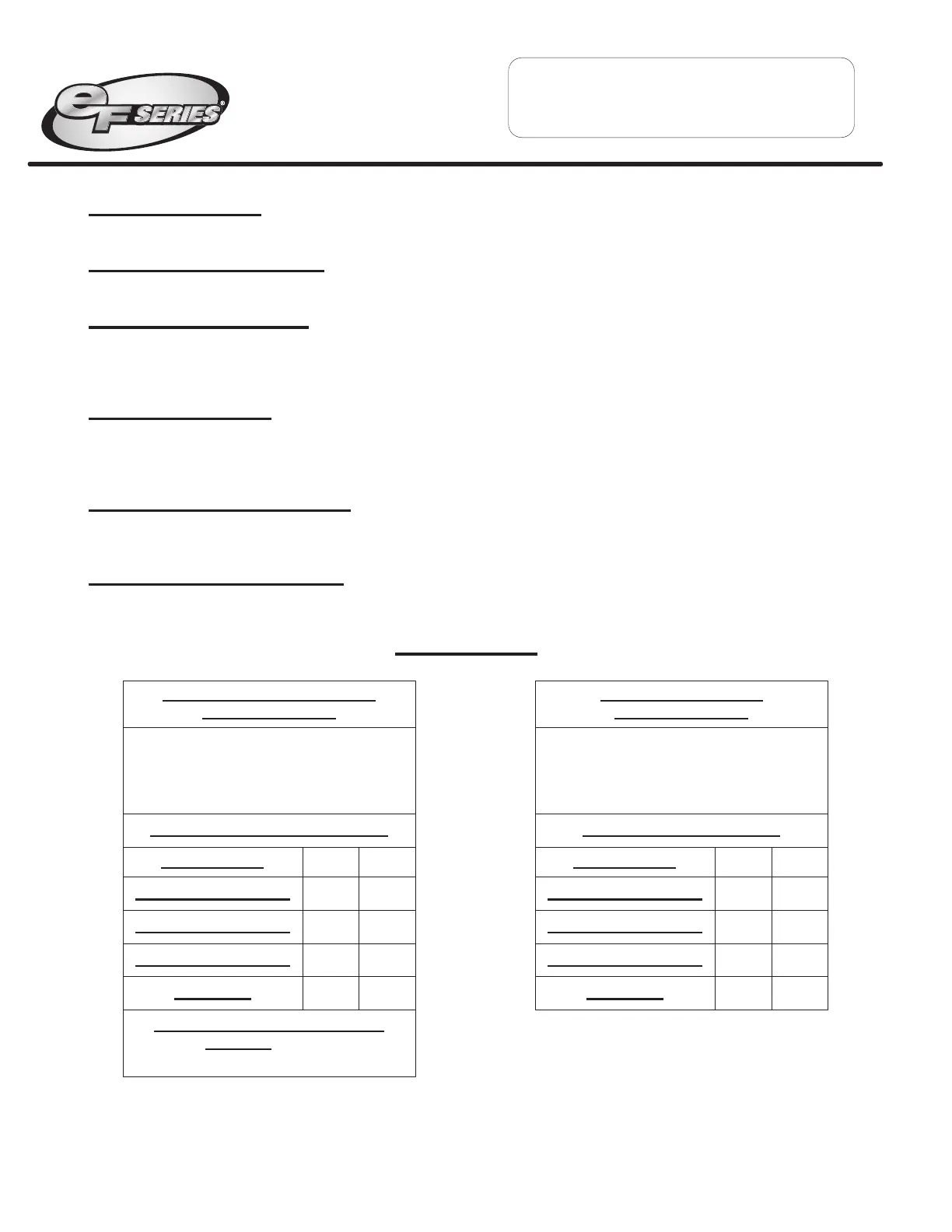

Balanced Direct Vent Systems

PVC, CPVC or ABS

Total length of intake piping and exhaust

piping added together must not exceed

“Maximum Combined Length”

Shown below

Maximum Combined Length (feet)

Model Number 3"

EF60T125, EF100T150 120'

EF60T150, EF100T199

EF60T199, EF100T250

EF100T300

Unbalanced Direct Vent Systems

Air intake CAN NOT exceed exhaust by

more than 30 feet

100'

80'

60'

4"

170'

150'

130'

110'

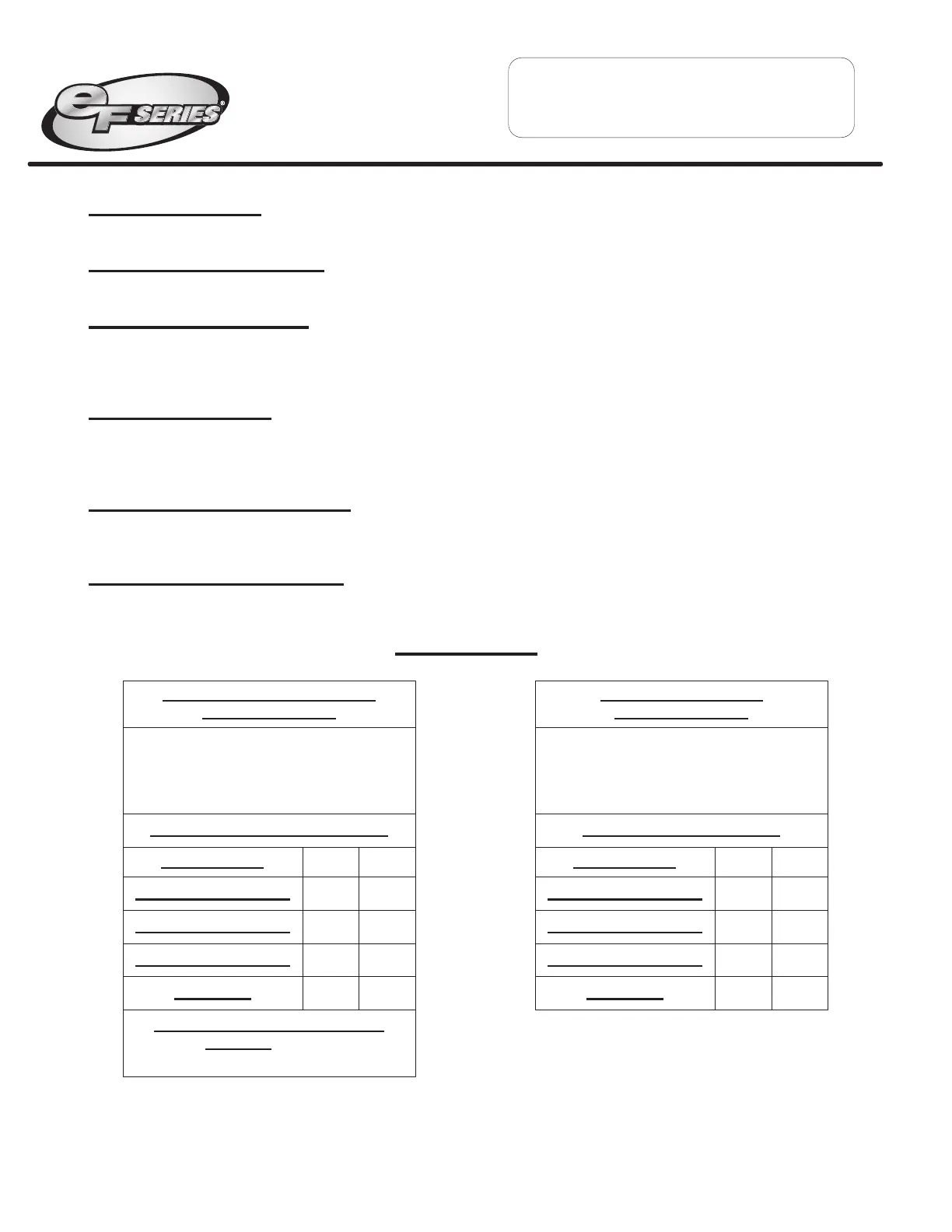

Power Vented Systems

PVC, CPVC or ABS

Total length of exhaust piping must not

exceed “Maximum Vent Length”

Shown below

Maximum Vent Length (feet)

Model Number 3"

EF60T125, EF100T150 120'

EF60T150, EF100T199

EF60T199, EF100T250

EF100T300

100'

80'

60'

4"

170'

150'

130'

110'

Vent tables

Note: each 3" & 4" 90° Elbow is equivalent to 5 feet of straight pipe.

Note: each 3" & 4" 45° Elbow is equivalent to 2.5 feet of straight pipe.

Page 44

R

Loading...

Loading...