PROBLEM DETERMINATION

AND

SOLUTION

Precautions

1.

Be

sure

to

turn

the power switch

OFF

before opening

the

control

box.·~over

or

plugging I unplugging

the

power cord.

2.

When replacing a fuse,

be

sure

to

use

a new one having the

same

quality and capacity

as

the old one.

Problem

determination

and

solution

table

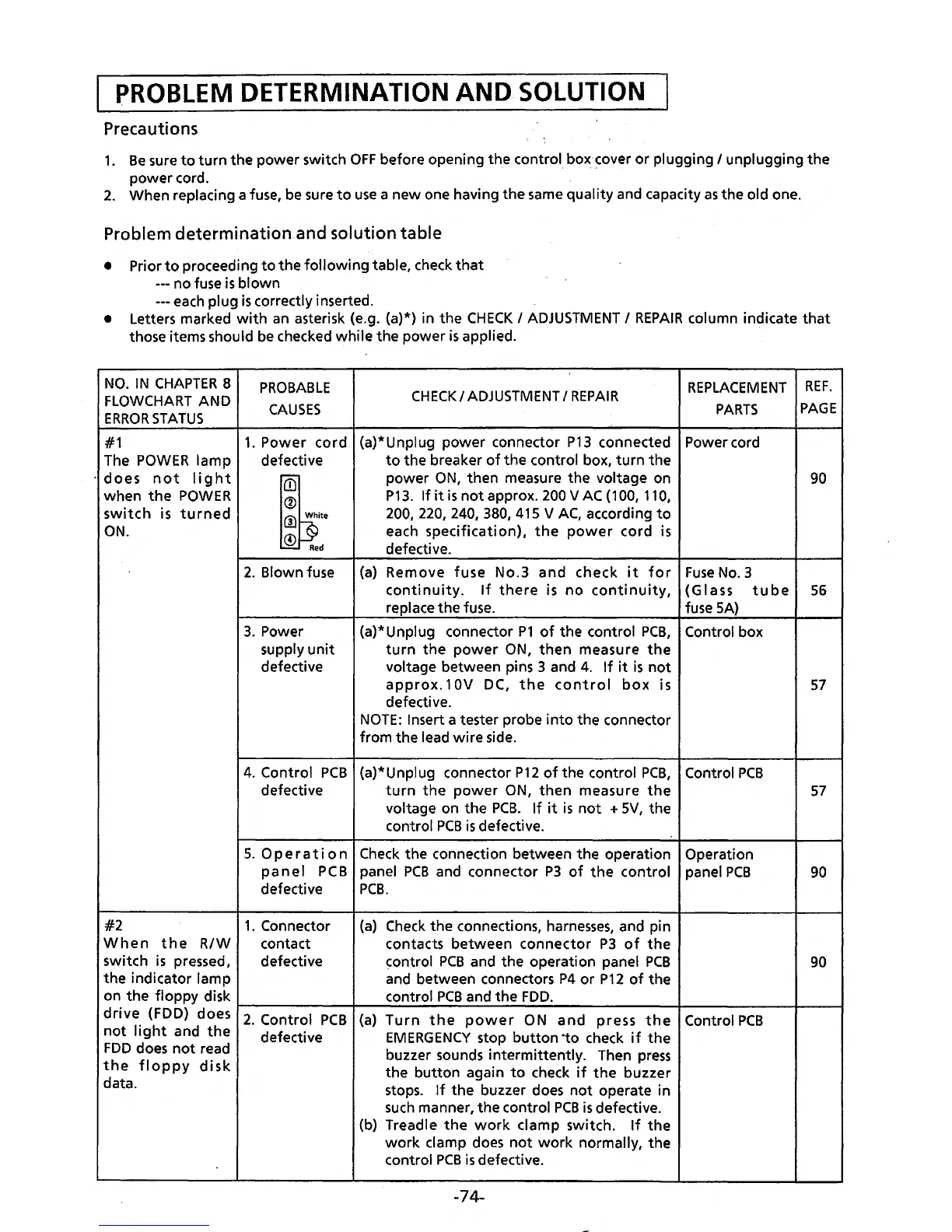

• Prior

to

proceeding

to

the

following

table, check

that

---no

fuse

is

blown

---each plug

is

correctly inserted.

• Letters marked

with

an

asterisk (e.g. (a)*) in

the

CHECK

I

ADJUSTMENT

I

REPAIR

column indicate

that

those items should

be

checked

while

the power

is

applied. ·

NO.

IN

CHAPTER

8

FLOWCHART

AND

ERROR

STATUS

#1

The

POWER

lamp

·does

not

light

when

the

POWER

switch

is

turned

ON.

PROBABLE

CAUSES

1.

Power

cord

defective

{15

®

ro

[§;ite

~

Red

2.

Blown fuse

3.

Power

supply

unit

defective

CHECK/

ADJUSTMENT

I

REPAIR

{a)*Unplug

power

connector

P13

connected

to

the

breaker

of

the control box,

turn

the

power

ON,

then

measure the voltage on

P13.

If

it

is

not

approx.

200

V

AC

(1

00,

110,

200, 220, 240, 380, 415 V

AC,

according

to

each

specification),

the

power

cord is

defective.

(a)

Remove

fuse

No.3

and

check

it

for

continuity.

If

there

is

no

continuity,

replace

the

fuse.

{a)* Unplug connector

P1

of

the control

PCB,

turn

the

power

ON,

then

measure

the

voltage between pins 3 and

4.

If

it

is

not

approx.

1

OV

DC,

the

control

box

is

defective.

NOTE:

Insert a tester probe

into

the

connector

from

the

lead

wire

side.

REPLACEMENT

REF.

PARTS

PAGE

Power cord

90

Fuse

No.3

(Glass

tube

56

fuse

SA)

Control box

57

4.

Control

PCB

(a)* Unplug connector

P12

of

the control

PCB,

Control

PCB

defective

turn

the

power

ON,

then

measure

the

57

voltage on the

PCB.

If

it

is

not

+ 5V, the

control

PCB

is

defective.

5.

Operation

Check

the connection between the operation Operation

panel

PCB

panel

PCB

and connector

P3

of

the

control

panel

PCB

90

defective

PCB.

#2

1.

Connector

(a)

Check

the

connections,

harnesses,

and pin

When

the

R/W

contact contacts

between

connector

P3

of

the

switch

is

pressed, defective control

PCB

and

the

operation panel

PCB

90

the

indicator lamp and between connectors

P4

or

P12

of

the

on

the

floppy disk control

PCB

and the

FDD.

drive

(FDD)

doesr2-_-c_o_n_t-ro_I_P_C_B-+{-a_)_T~u-r_n

__

t_h_e

____

p_o_w_e_r

__

O_N

__

a_n_d

___

p_re_s_s

__

th-e-4-C-o-n-tr_o_IP_C_B--~~----~

not

light

and

the

defective

EMERGENCY

stop

button

·to check

if

the

FDD

does

not

read buzzer sounds intermittently. Then

press

the

floppy

disk

the

button

again

to

check

if

the

buzzer

data. stops.

If

the

buzzer does

not

operate in

such

manner, the control

PCB

is

defective.

(b) Treadle

the

work

damp

switch.

If

the

work

damp

does

not

work

normally, the

control

PCB

is

defective.

-74-

Loading...

Loading...