4.

1/0

checking

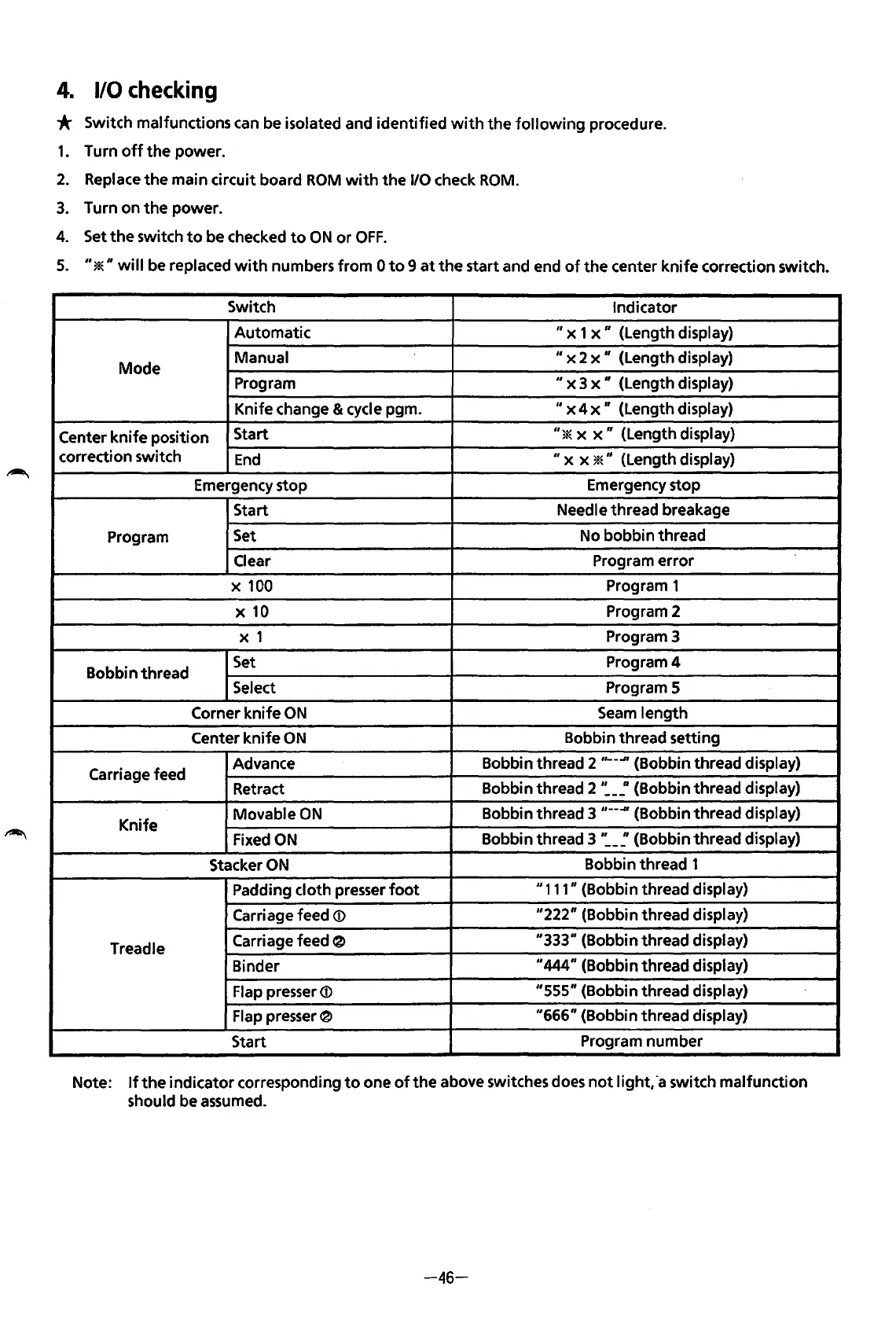

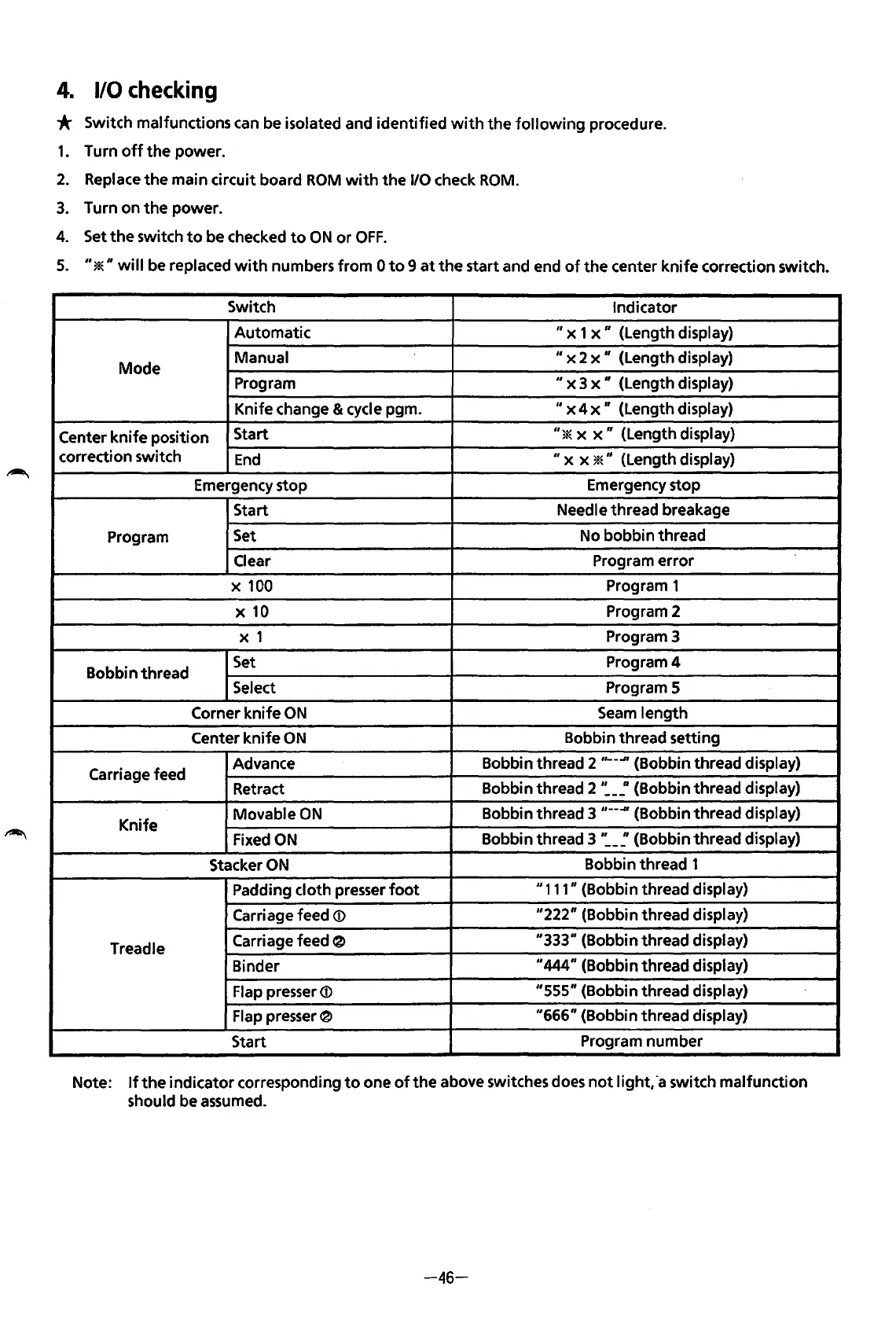

* Switch malfunctions can be isolated and identified

with

the

following

procedure.

1.

Turn

off

the

power.

2.

Replace

the

main circuit board

ROM

with

the

1/0 check

ROM.

3.

Turn on

the

power.

4.

Set

the

switch

to

be checked

to

ON

or

OFF.

5.

"*"will

be

replaced

with

numbers

from

0

to

9

at

the

start and end

of

the

center

knife

correction switch.

Switch

Indicator

Automatic

" x 1 x

11

(Length display)

Mode

Manual

11

x 2 x

11

(Length display)

Program

II

x 3

x"

(Length display)

Knife change & cycle pgm.

II

x 4 x " (Length display)

Center

knife

position

Start

"*

x

x"

(Length display)

correction switch

End

II

x x *" (Length display)

Emergency stop

Emergency stop

Start

Needle thread breakage

Program

Set

No bobbin thread

Clear

Program error

X

100

Program 1

X

10

Program 2

X 1

Program 3

Bobbin thread

Set

Program4

Select

Program 5

Corner knife

ON

Seam

length

Center knife

ON

Bobbin thread setting

Carriage feed

Advance

Bobbin thread 2

,,__..n

{Bobbin thread display)

Retract

Bobbin thread 2

·:-~(Bobbin

thread display)

Knife

Movable

ON

Bobbin thread 3 ,

__

-#{Bobbin thread display)

Fixed

ON

Bobbin thread 3

':-~(Bobbin

thread display)

Stacker

ON

Bobbin thread 1

Padding cloth presser

foot

11

111" (Bobbin thread display)

Carriage feed

<D

"222" {Bobbin thread display)

Treadle

Carriage feed

~

"333" (Bobbin thread display)

Binder

11

444" (Bobbin thread display)

Flap presser

<D

"555" (Bobbin thread display)

Flap presser 0

"666"

(Bobbin thread display)

Start

Program number

Note:

If

the

indicator corresponding

to

one

of

the

above switches does

not

light,

·a

switch malfunction

should be assumed.

-46-

From the library of: Superior Sewing Machine & Supply LLC

Loading...

Loading...