Maintenance | 8

Instruction Manual R5 RB_RC 0021 C_EN_en 17 | 32

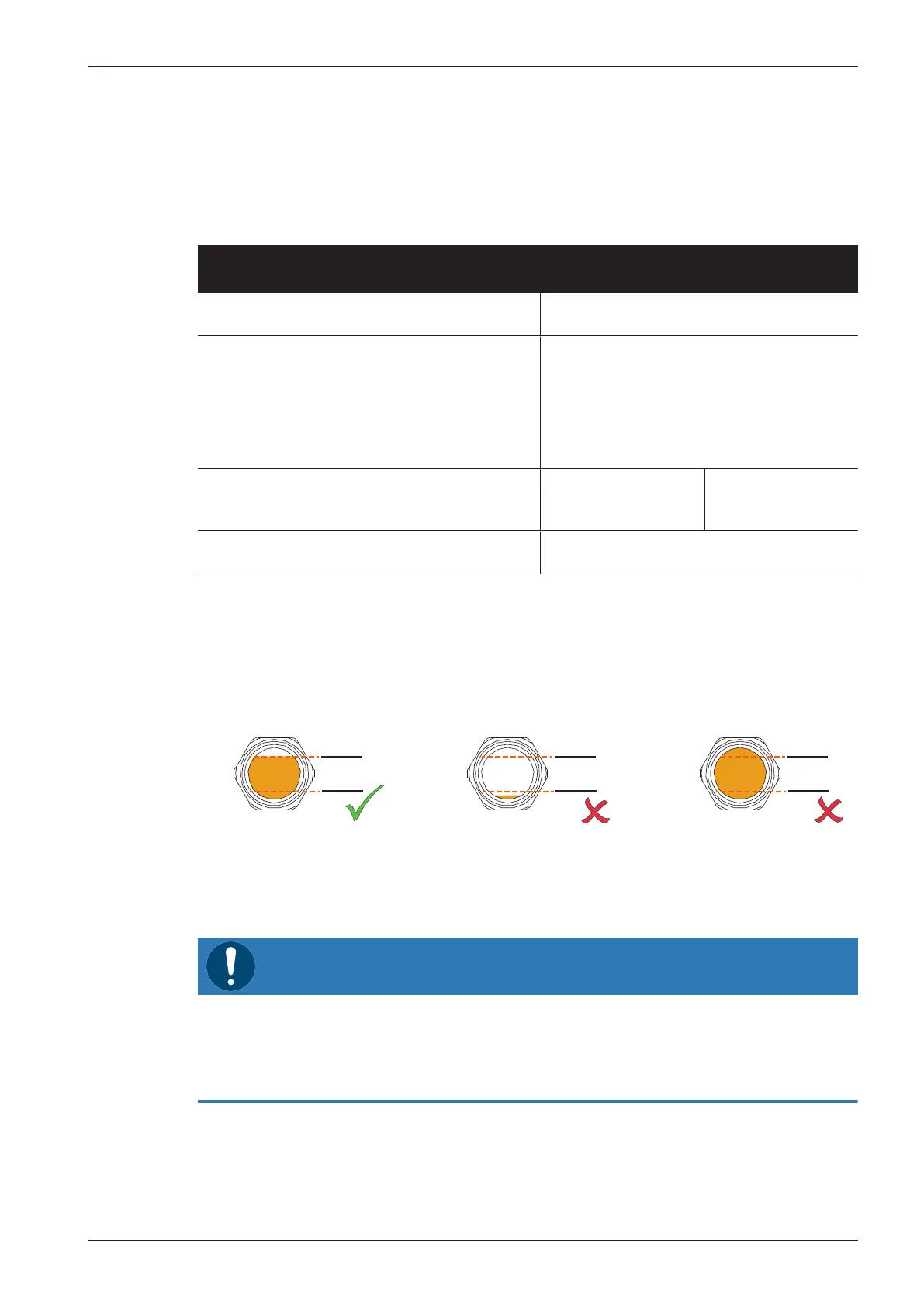

8.1 Maintenance Schedule

The maintenance intervals depend very much on the individual operating conditions. The intervals

given below are considered as starting values which should be shortened or extended as appropri-

ate. Particularly harsh applications or heavy duty operation, such as high dust loads in the environ-

ment or in the process gas, other contamination or ingress of process material, can make it neces-

sary to shorten the maintenance intervals significantly.

Maintenance work Interval

Normal application Harsh application

● Check the oil level, see Oil Level Inspection

[➔17].

Daily

● Check the machine for oil leaks - in case of

leaks have the machine repaired (contact Bus-

ch).

In case of an inlet filter being installed:

● Check the inlet filter cartridge, replace if neces-

sary.

Monthly

● Change the oil*, the oil filter* (OF) and the ex-

haust filters (EF).

Max. after 4000 hours,

at the latest after 1

year

Max. after 2000

hours, at the latest

after 6 months

● Contact Busch for an inspection.

If required, overhaul the machine.

Every 5 years

* Service interval for synthetic oil, shorten the interval when using mineral oil, contact Busch Service

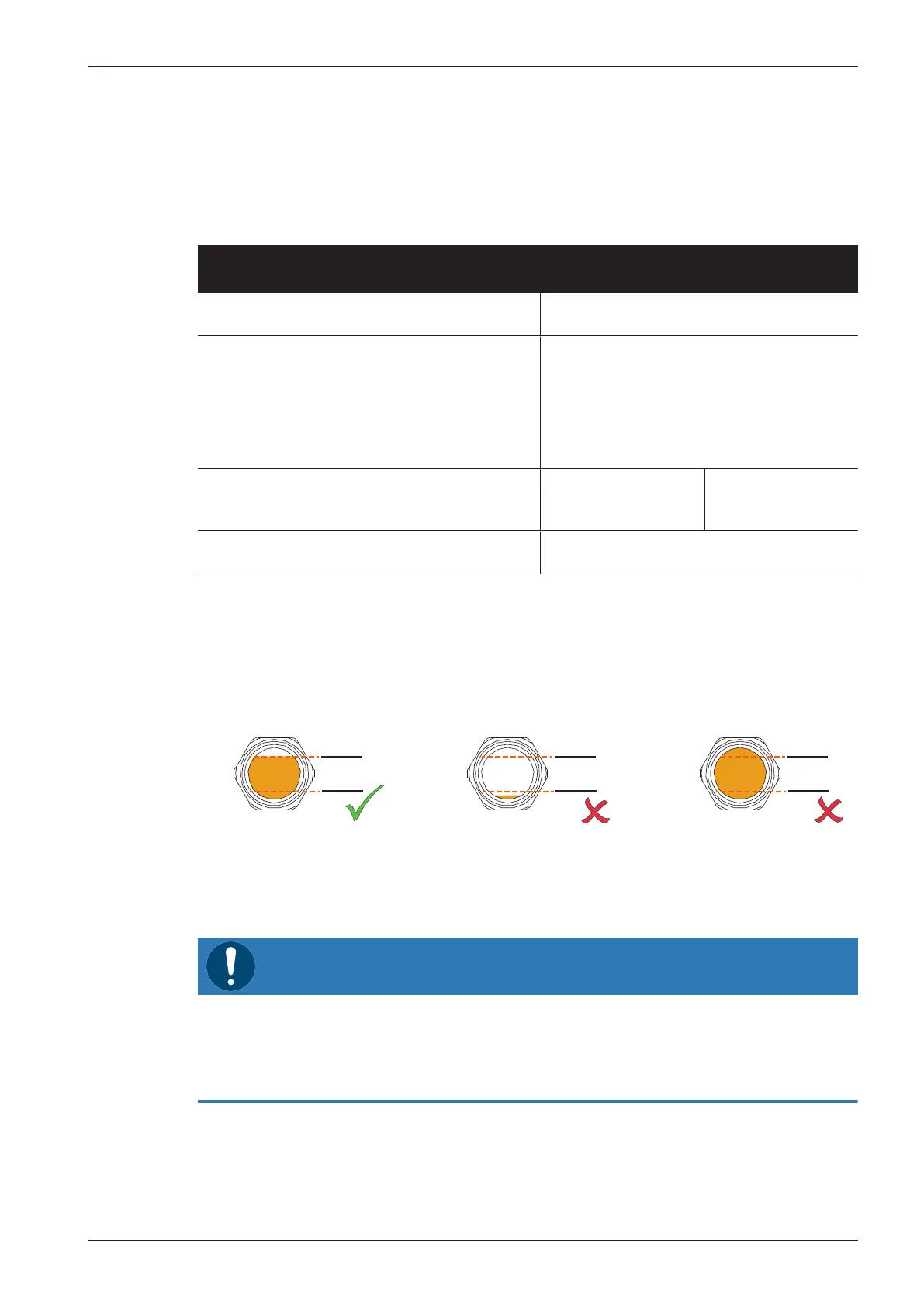

8.2 Oil Level Inspection

● Shut down the machine.

● When the machine is stopped, wait 1 minute before checking the oil level.

● Fill up if necessary, see Oil Filling [➔11].

8.3 Oil Change

NOTICE

Use of an inappropriate oil.

Risk of premature failure!

Loss of efficiency!

● Only use an oil type which has previously been approved and recommended by Busch.

Loading...

Loading...