37

7.1 Scope

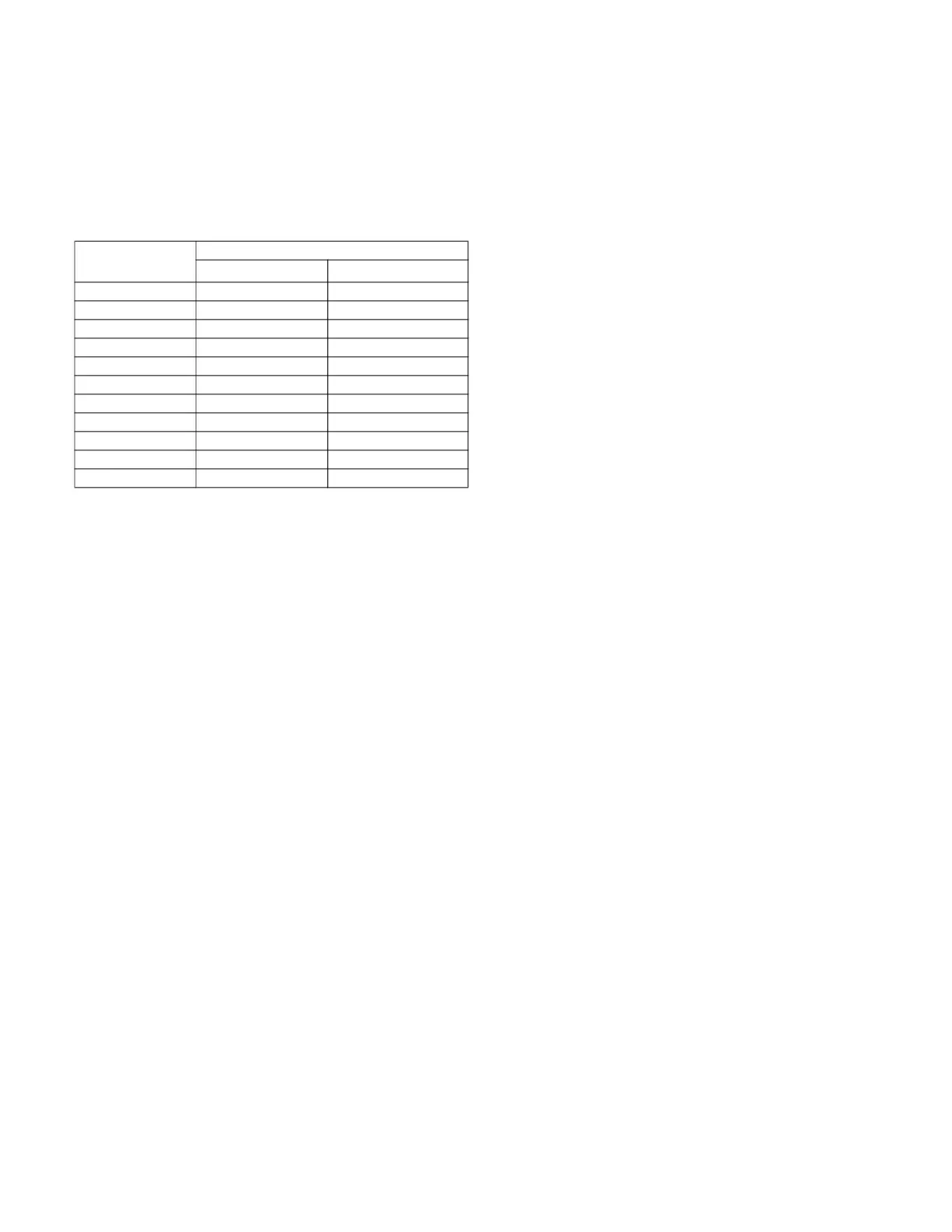

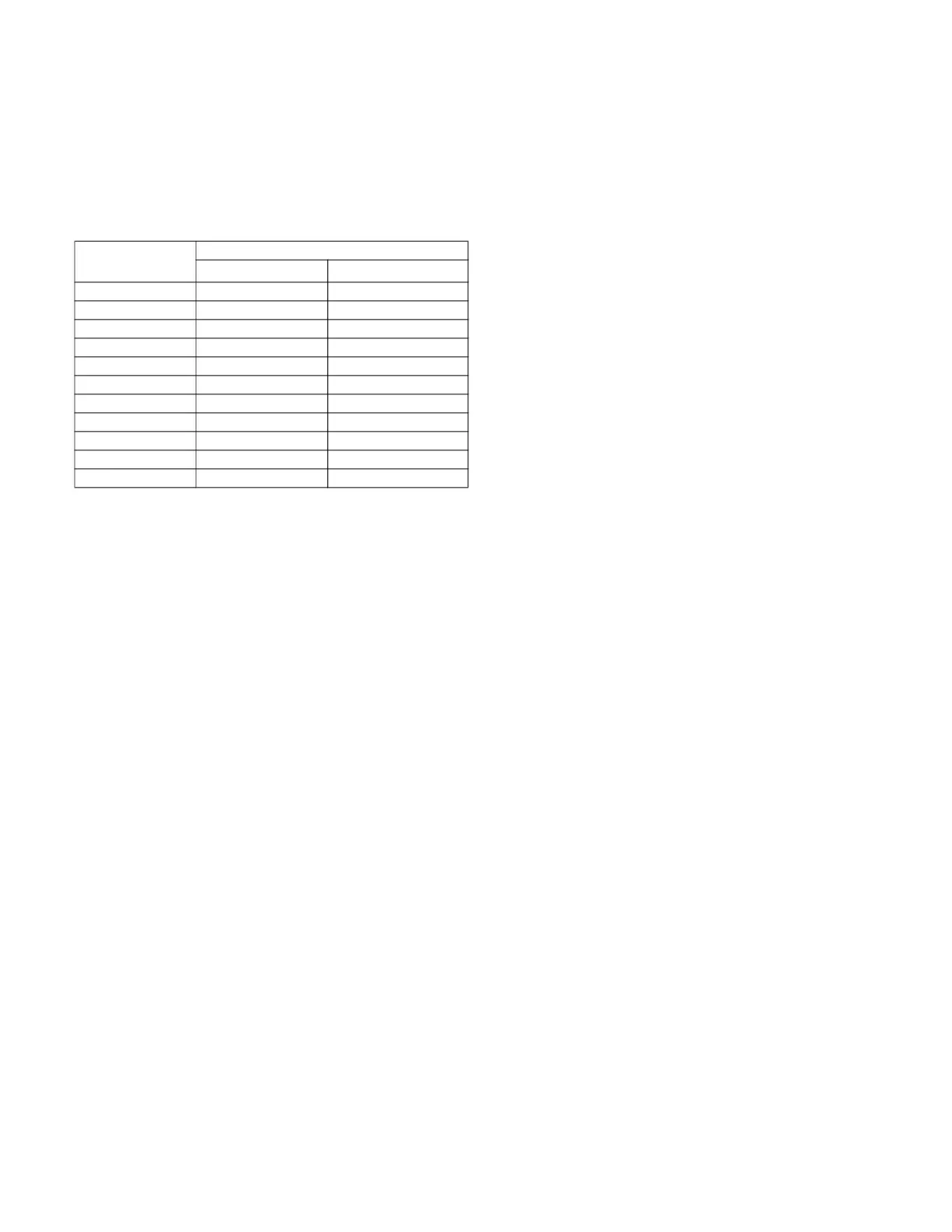

Carlyle has conducted an extensive qualification program

for our R-134a compressors and has approved most

compressors for VFD applications. A summary of the

qualified models is presented in Table 18.

Table 18 —Variable Speed Model Summary

NOTES:

1. See Application Engineering as approval is limited to certain applica-

tions.

2. See Application Engineering as compressor has been approved but

limited

performance data is available.

3. Standard model cannot be used for VFD applications. The “VS”

model must be ordered, which is identified by an “X” in the 5th digit of

the model number.

4. Variable speed operation is approved for all low/medium temperature

R-404A, R-407A, R-407C, R407F, R-448A, R-449A, and R-507A.

It may be possible to have the drive provide the compres-

sor motor protection, replacing the compressor over-

loads. Carlyle Application Engineering should be con-

tacted to verify that the overcurrent protection meets

Car

lyle's requirements for UL-rated motor overload pro-

tection and to verify the required overload settings.

It is important to work with the drive manufacturer to

select a drive appropriate for the application. Refrigera-

tion screw compressors provide a constant torque load-

ing to the drive and also have unique starting torque

requirements. The drive should not be sized on the nomi-

nal HP rating of t

he compressor, but based on the nomi-

nal electrical data, including RLA and LRA (available in

Section 8.3), along with the operating power and amper-

age at the max load design condition. It is important that

the appropriate criteria are taken into consideration when

selecting the type and size of the drive.

It is also important to review items associated with the

wiring of the compressor and associ

ated control system

wiring, as special precautions may be required to avoid

interference between the drive and other control wiring.

There may also be restrictions on the length and routing

of the wires from the drive to the compressor. These

items should be reviewed with the drive manufacturer to

ensure all application guidelines are followed when

installing the drive.

7.2 Capacity Control

The compressors have been approved with an allowable

speed range from 30 to 60 Hz. The capacity at 30 Hz will

be approximately 50% of the full load capacity and will

vary linearly in direct proportion to the speed.

It is possible to operate the compressors with a combina-

tion of slide valve and VFD control. The compressor can

be operated at minimum speed of 30 Hz and the slide

valve used for further unload

ing as long as appropriate

discharge and motor temperature limits are observed.

The compressor slide valve should remain in the fully

loaded position while the VFD is controlling compressor

capacity between 30 to 60 Hz. The slide valve may be

used to reduce compressor capacity below 50% (30hz) if

required.

Discharge Temperature

1. Compressor must be forced to 100% load if discharge

temperature 200°F (93.3°C).

2.

Unloading control must limit further unloading if dis-

charge temperature 190°F (87.8°C)

Motor Temperature

1. Compressor must be forced to 100% load if motor tem-

perature 265°F (129.4°C).

2. Unloading control must limit further unloading if motor

temperature 260°F (126.7°C)

NOTE: Different temperature limits may be required

depending on the accuracy and response time of the

sensors and control system that is used as well as the

overall stab

ility of the system and desired safety factor.

7.3 Power Supply

The variable speed drive should fix the output voltage

based on a constant Volts-per-Hz curve running through

the nominal voltage (380V/60Hz, 460V/60Hz) regardless

of the nominal voltage supplied to the drive. The drive

should maintain a constant V-Hz over the range of opera-

tion and should limit the speed of the drive if the appropri-

a

te voltage cannot be maintained. Over voltage should

be limited to +10% and under voltage limited to –15%.

Under voltage should limit the speed (Hz) until the con-

stant V-Hz curve is reached. Over voltage should limit

operation at the maximum speed, 60 Hz. The VFD

should also limit the amperage of the compressor to

90% of the MCC (maximum continuous current) value

(lower amperage limits may be applied depending on the

application). It may be neces

sary to limit the speed of the

MODEL

NUMBER

APPROVED FOR VARIABLE SPEED

AIR-COOLED

WATER-COOLED

3

06TS-137 Note 1 and 2 N/A

06TS-155 YES N/A

06TS-186 YES N/A

06TT-266 YES Note 1

06TT-301 YES Note 1

06TT-356 YES Note 1

06TU-483 YES YES, Note 3

06TU-554 YES YES, Note 3

06TV-680 YES YES, Note 3

06TV-753 Note 2 YES, Note 3

06TV-819 YES Note 2 and 3

7.0 Variable Frequency Drive Guidelines

Loading...

Loading...