4.6 - Actuators

■ Electronic Expansion Valve: The electronic expansion valve

(EXV) is used to adjust the refrigerant ow to changes in the

operating conditions of the machine. The high degree of

accuracy with which the piston is positioned provides precise

control of the refrigerant ow and suction superheat.

■ Staging valve: The staging valve is used during the start of

the compressor to route its ow through a bypass and to enable

the compressor start in proper conditions.

■ Evaporator ow switch: A ow switch is mounted to ensure

that the minimum ow rate required for the correct operation and

protection of the system is maintained. If the ow switch fails, the

alarm condition shuts off the unit. The ow switch can also be

added in the condenser exchanger (not provided with the unit).

■ Variable-speed water pumps: The controller provides a

command of speed for the evaporator water loop. The water

ow control is based on the heat exchanger temperature

difference.

■ Water pumps (optional): The unit can be tted with one

evaporator and one condenser pump. The controller can

independently regulate each water heat exchanger pump.

4.7 - Terminal block connections

The “Terminal block connections” table given below summarizes

connections at the user terminal block. Connections available at

the user terminal block may vary depending on the selected options.

IMPORTANT: Some contacts can be accessed only when the

unit operates in Remote mode.

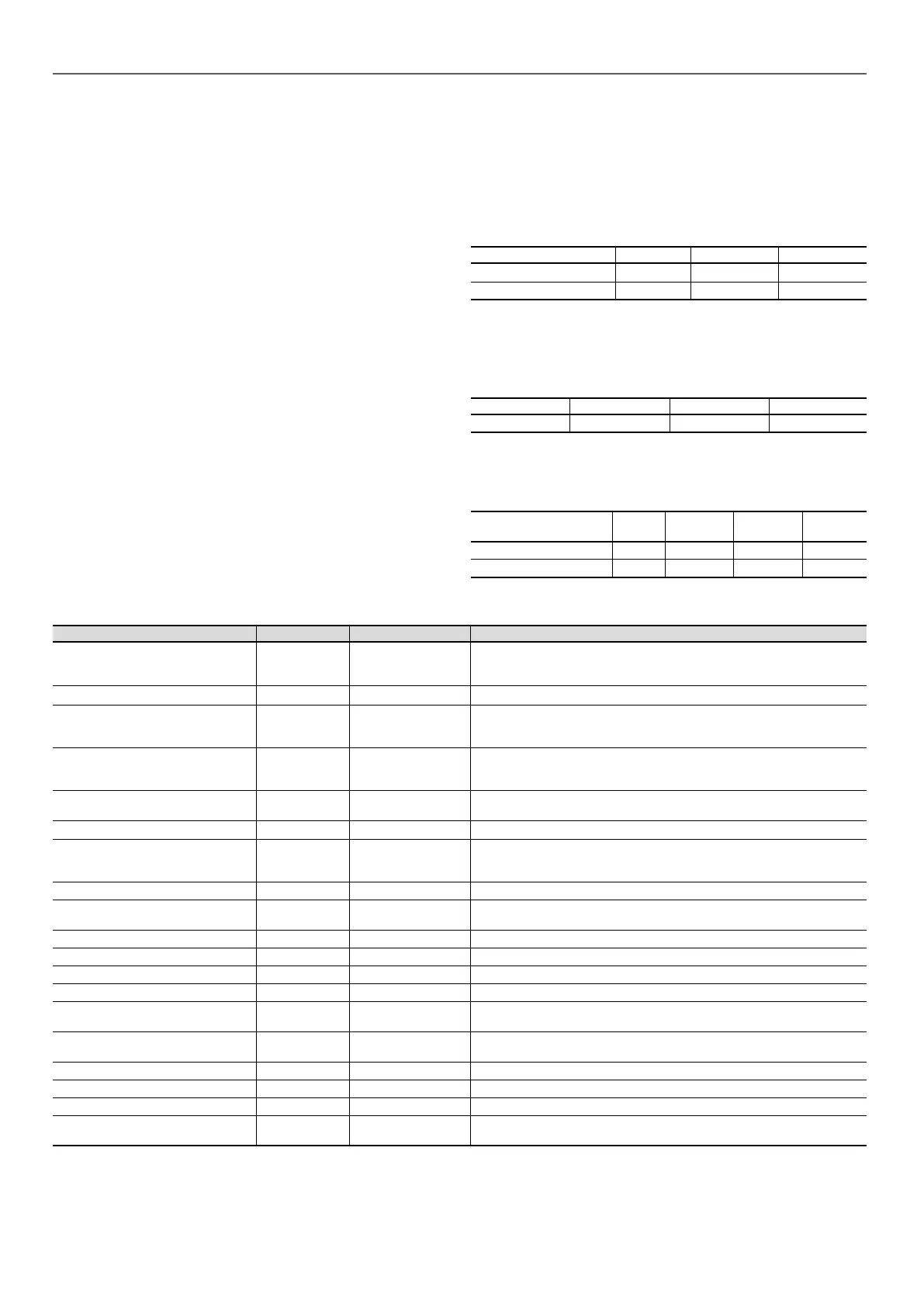

4.7.1 - Volt-free contact (on/off and cool/heat)

Contact Off Cooling Heating

On/Off switch open closed closed

Heat/Cool switch open open closed

4.7.2 - Volt-free setpoint selection contact

When the unit is under remote control, the volt-free contact is used

to determine the active setpoint. This dry contact is used to switch

between setpoints.

Contact Setpoint 1 Setpoint 2 Setpoint 3

Setpoint switch open closed closed

* Ice done contact must be open to enable “setpoint 3”

4.7.3 - Volt-free demand limit selection contact

Two dry contacts can be used to limit unit capacity.

Contact 100%

Limit 1

[lim_sp1]

Limit 2

[lim_sp2]

Limit 3

[lim_sp3]

Demand limit switch #1 open closed open closed

Demand limit switch #2 open open closed closed

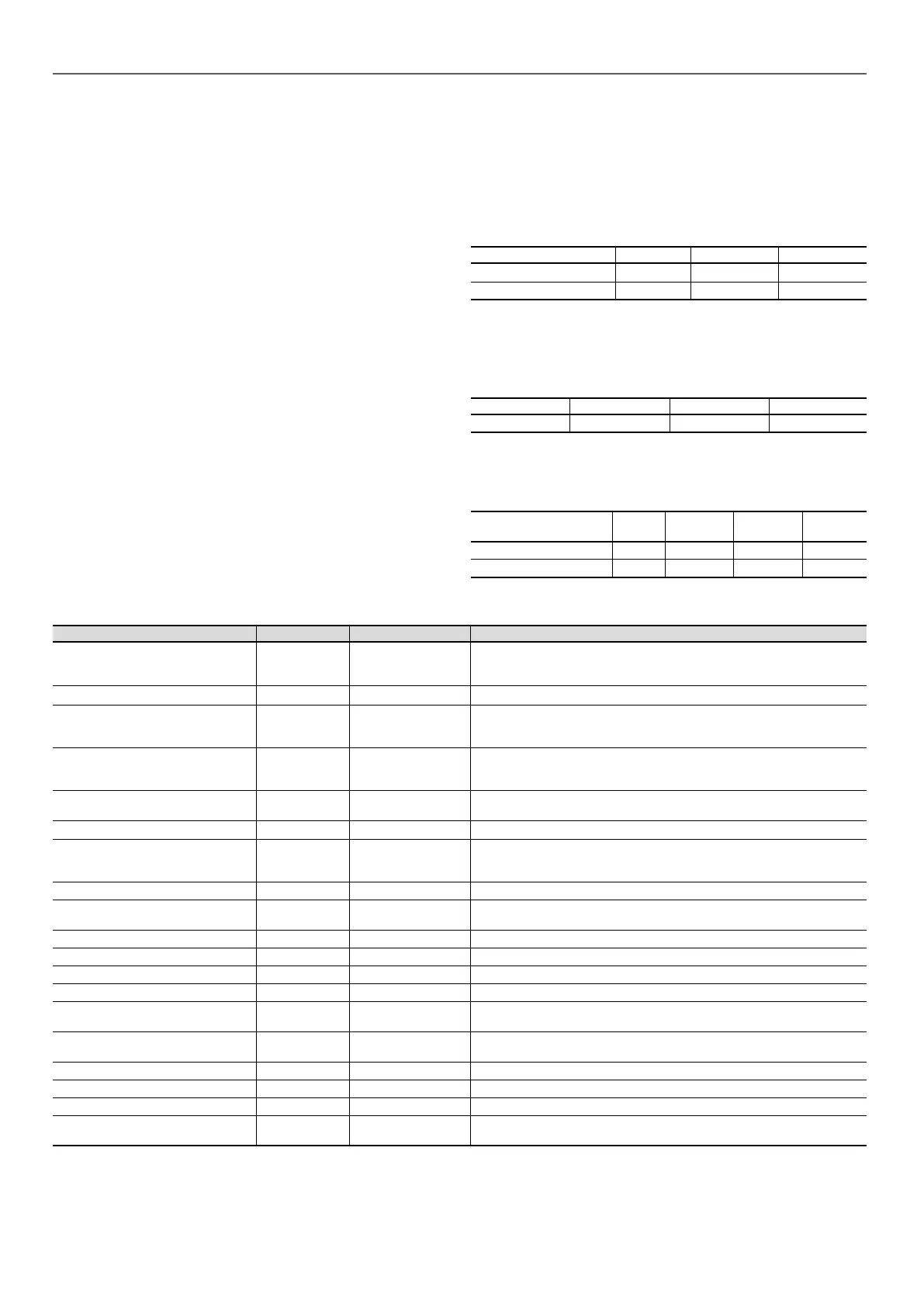

4 - HARDWARE DESCRIPTION

Terminal block connections

Description Board Connector Remarks

On/Off switch SIOB #1 DI-01, 32-33

Used for the unit on/off control (Remote mode only):

open = unit is Off

closed = unit is on

Heat/Cool Switch SIOB #1 DI-02, 63-64 Used to switch between heating and cooling (Remote mode only)

Demand Limit Switch #1 SIOB #1 DI-03, 73-74

Used to control demand limit:

open = 100% capacity can be used, no demand limitation is applied

closed = demand limitation applied

Customer interlock SIOB #1

DI-04, 34-35

- Bypass

Used to control unit start/stop:

open = unit shuts down

closed = unit is allowed to operate

Setpoint Switch SIOB #1 DI-05, 65-66

When the unit is under remote control, the volt-free contact is used to

determine the active setpoint (see section 8.4.1)

Setpoint reset SIOB #1 AI-10, 71-72 4-20 mA signal to offset the active setpoint of the unit

Alarm relay * SIOB #1 DO-05, 30A-31A

Used to signal an alarm:

open = inactive (no alarms active)

closed = alarm(s) active

Running Relay SIOB #1 DO-06, 37-38 Used to signal a running status (at least one compressor start)

External Pump Speed Command

of the evaporator

SIOB #1 AO-01, 90+ 90 - Used to control the speed of a pump by a 0-10V signal

3-way valve control AUX1 #1 Ch 9, 80+ 80- Used to control a three way valve on the condenser water loop (optional)

Occupied Override Switch SIOB #3 DI-01, 77-78 In Remote mode closing this switch set occupancy to "yes"

Demand Limit Switch #2 SIOB #3 DI-02, 73A-74A In remote mode enables the 2nd capacity limit setpoint

Ice setpoint SIOB #3 DI-03, 75-76 Closing this input disables the ice setpoint

Condenser ow switch SIOB #3

DI-05, 96-97

- Bypass

Used to detect the ow on the condenser side. It should be closed to

authorise the unit to start

Space temperature for reset

control

SIOB #3 AI-01, 71A-72A Space temperature for reset control

Capacity limit control SIOB #3 AI-10, 67-68 4-20 mA signal to set the demand limit of the unit

Chiller Alert state * SIOB #3 DO-05, 30B-31B Closed if an alert is present

Chiller shutdown state * SIOB #3 DO-06, 30-31 Closed if chiller is shutdown

Chiller capacity running output

(0 to 10V)

SIOB #3 AO-01, 79+ 79-

Used to transmit the voltage level corresponding to unit production

(10V = production at full capacity)

* These signals can be reversed by setting the parameter al_rever to “yes” in the GEN_CONF table.

8

Loading...

Loading...