20

Refrigerant piping

Eliminate any residual moisture in the lines. Copper

plating, formation of acid sludge, freezing of the

laminating devices, formation of acids that corrode

metals and deteriorate the insulation of the electric motor

can occur in the case of non-compliant installation with

the presence of moisture. See paragraph “6.3 Vacuum

operation” page 40

Avoid weld undercutting that cannot be inspected; all the

piping must be accessible for inspection.

a

CAUTION

To prevent the refrigerant pipes from oxidising

during welding, charge with nitrogen.

In case of laying the lines before making the connection

to the units, keep the ends sealed until the time of

connection.

It is good practice to pinch the ends in case the lines are

laid a long time before the connection.

a

CAUTION

Use only nitrogen as a cleaning agent.

If residual moisture is found when cleaning with the

blowing of nitrogen, or if a long time has passed between

the laying of the lines and the connection, proceed with

the "triple vacuum".

This procedure consists in filling with nitrogen and

emptying twice before carrying out the final emptying

operation.

Make sure that the pressure does not rise during this

operation.

It is important that the joints are created to standard to

ensure a good seal.

For more information see paragraph “6.1 Flushing the

pipes” page 39 and “6.2 Gas leak test” page 39

l

WARNING

For connection of the lines, only “braze”

welding is allowed.

Brazing (1) consists in connecting metal pieces with the

help of a filler metal without melting the pieces to be

assembled. The filler metal penetrates by capillarity

between the pieces to be assembled.

The filler metal must be phosphorous copper or "rods of

silver alloy".

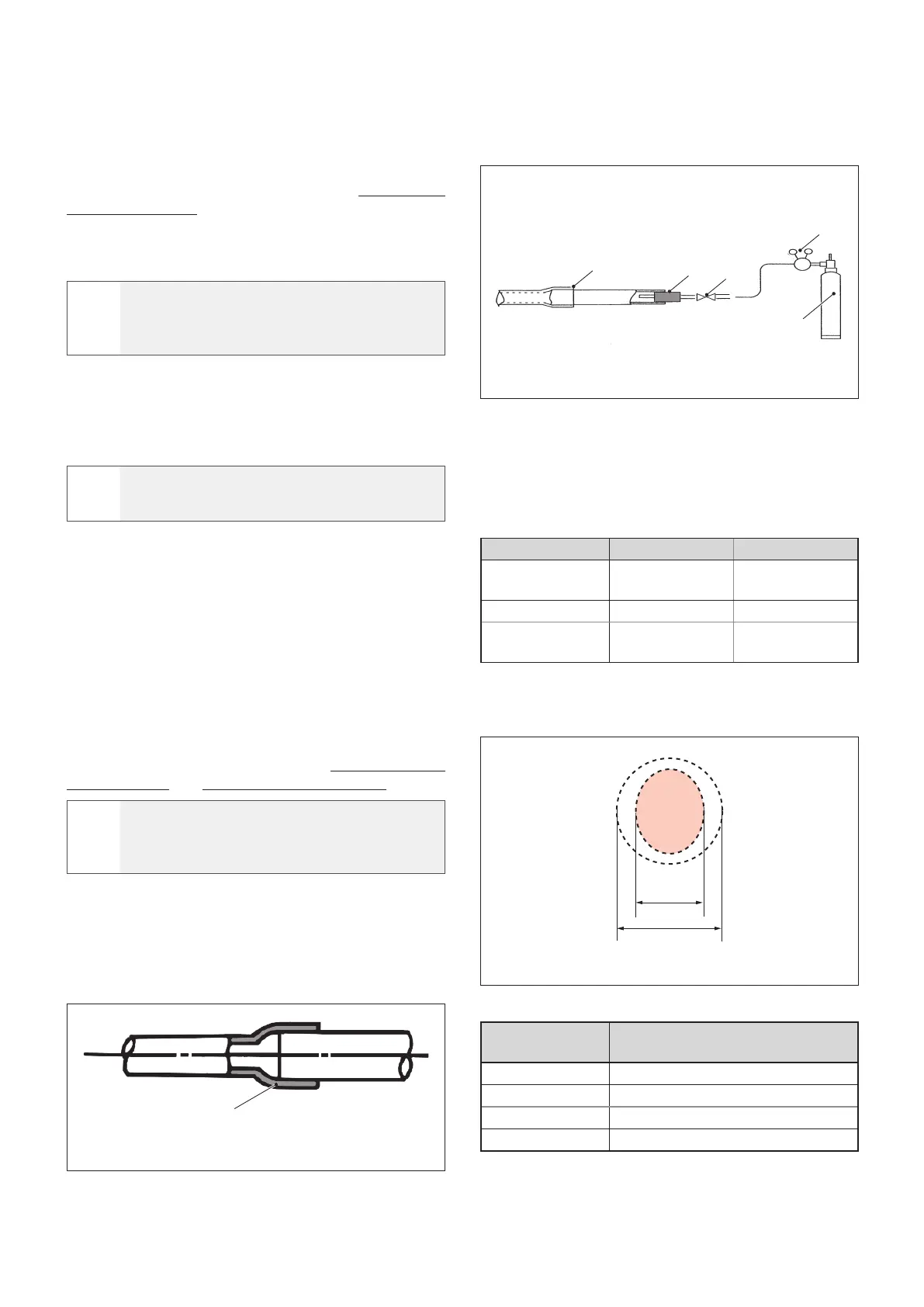

1

Fig. 23

Welding must be done in a neutral atmosphere (nitrogen).

An inert atmosphere (free of moisture and oxygen) must

be created inside the pipeline. In this way, no oxide

formations are created during welding

1

2

3

4

5

Fig. 24

1

Weld point

2

Rubber cap

3

Pressure reducer (operating pressure 0.2/0.5bar)

4

Pressure reducer on the cylinder

5

Cylinder of nitrogen

Connection method

Gas side Liquid side

Indoor unit

Welding or

flaring

Welding or

flaring

Outdoor unit Flaring Flaring

Branch pipe

Welding or

flaring

Welding or

flaring

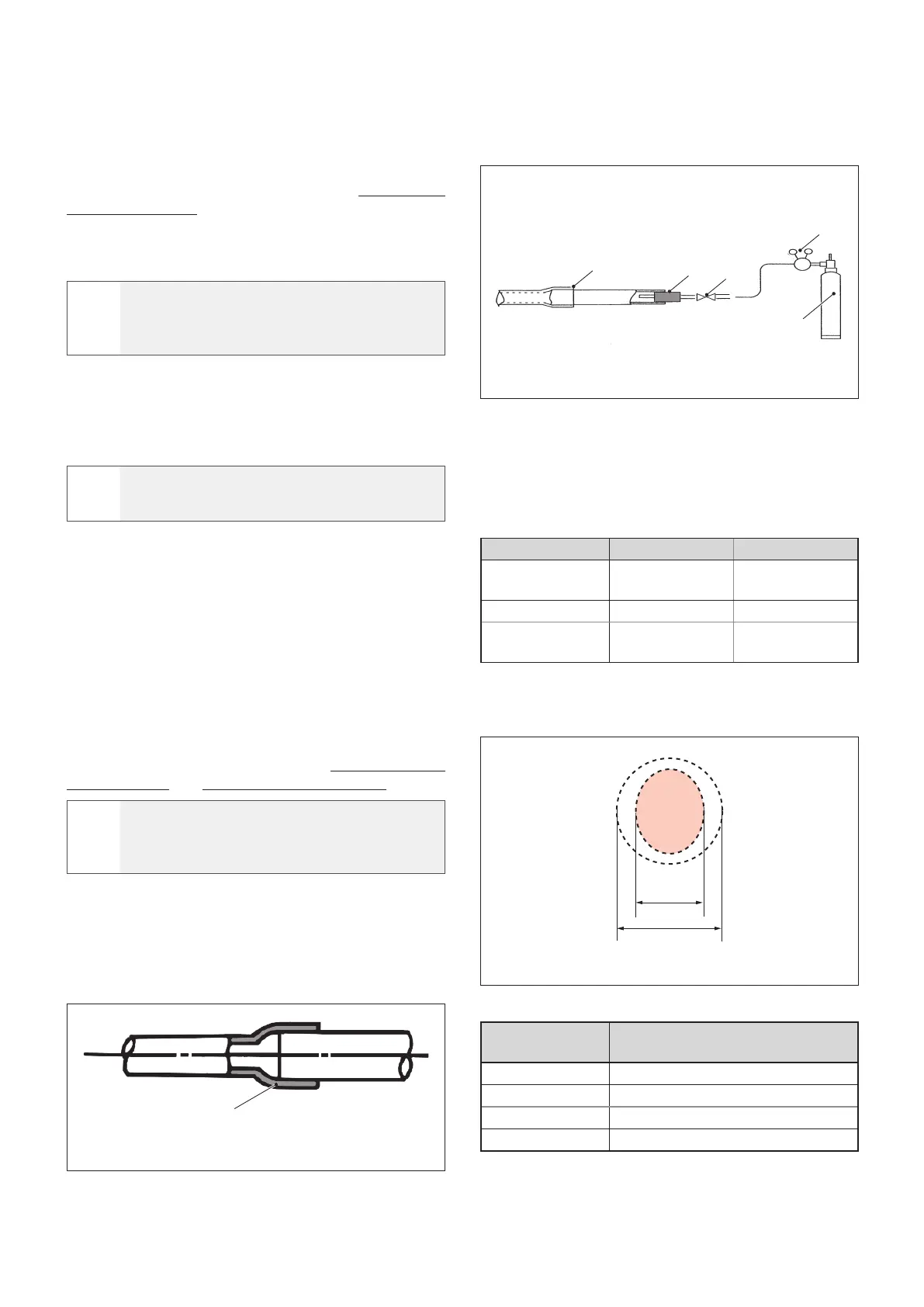

If it is necessary to bend the piping, the risk of excessive

deformation must be avoided. The maximum deformation

allowed is 2/3rds of the diameter of the pipe itself.

2/3 Ø

Ø

Fig. 25

Pipes can be bent respecting the following bending radii:

Pipe diameter

(mm)

Radius (mm)

9.52

≥ 30

12.7

≥ 30

15.9

≥ 40

19.1

≥ 50

Loading...

Loading...