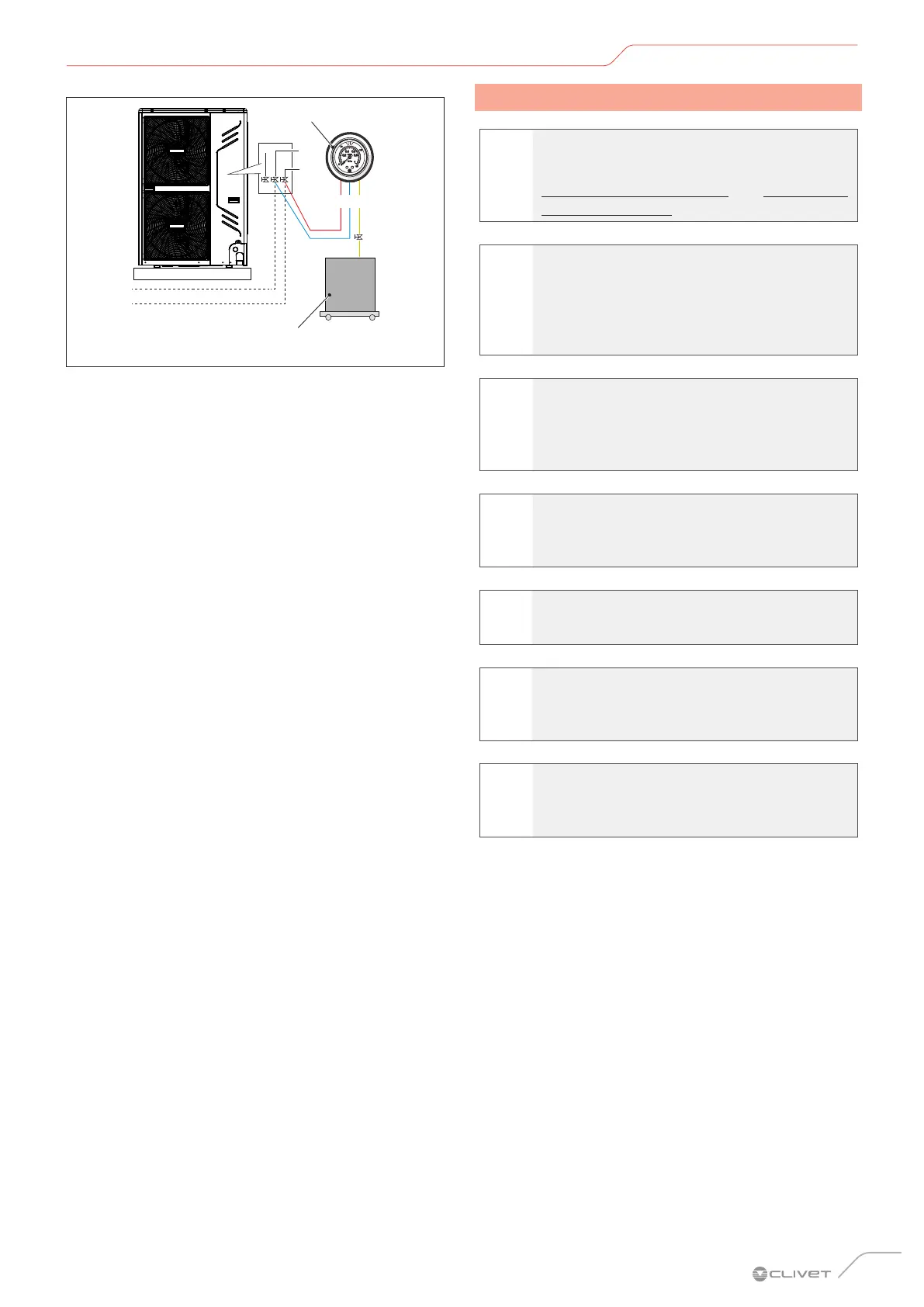

41

Starting up the system

2

33

A

B

C

Fig. 65

– Activate the vacuum pump. Open the valves of the

pressure gauge to start creating a vacuum in the

system.

– After 30 minutes close the valves of the pressure

gauge.

– If within 5/10 minutes the pressure gauge returns

to zero, there are leaks in the system. Proceed

with repair.

– Open the pressure gauge valves again and

continue drying for at least two hours and in any

case until a pressure dierence of 0.1 Mpa is

exceeded. Once this pressure is reached, continue

for another two hours.

– Close the pressure gauge valves.

– Stop the vacuum pump.

– If the pressure in the piping has not increased after

one hour, the procedure is over. If the pressure has

increased, there are leaks in the system.

When done, it is possible to keep the high and low

pressure hoses connected to the pressure gauge and

to the stop valves of the master unit for the purpose of

charging with refrigerant.

6.4 Charging with refrigerant

a

CAUTION

Charge the refrigerant only after having done

“6.2 Gas leak test” page 39 and “6.3 Vacuum

operation” page 40 .

a

CAUTION

Do not charge more refrigerant than necessary

because to do so can seriously compromise

the correct functioning of the refrigeration

circuit.

a

CAUTION

Use only R410A refrigerant. Charging with

other substances may cause an explosion and

fire.

m

CAUTION

When charging the refrigerant, wear suitable

PPE such as gloves and protective goggles.

m

CAUTION

Open the refrigerant containers slowly.

l

WARNING

Use only instruments and appliances designed

for use with R410A refrigerant.

l

WARNING

The refrigerant must be treated in compliance

with the regulations in force.

Loading...

Loading...