19

Refrigerant piping

4 REFRIGERANT PIPING

4.1 Installation of the refrigerant piping

Below are the guidelines for compliant installation of the

refrigerant piping

Put the outdoor unit in place

Put the indoor unit in place

Put the pipes in place

Blow with nitrogen

Perform welding

Make the connection to the units

Perform the tightness test

Carry out pressing and pressurisation

To perform all the operations correctly, you need the

following equipment:

– Pipe cutter

– Flaring tool

– Tube bending machine

– Vacuum pump

– Digital vacuum gauge

– Manifold and fittings

– Cylinder of nitrogen

– Electronic leak detector with sensitivity according

to current regulations.

l

WARNING

Pay attention to the maximum measurements

of the refrigerant piping. See paragraph “2.5

Length of refrigerant piping” page 13 .

l

WARNING

Use deoxidised phosphorous copper piping

for the refrigerant (seamless copper alloy

piping and tubing) compliant with local

regulations.

l

WARNING

Use piping suitable for use with R410A.

l

WARNING

Be careful not to touch the components when

connecting the pipes.

Keep the ends of the pipes sealed until installation to

prevent the ingress of polluting agents such as dust,

water and dirt.

Fig. 22

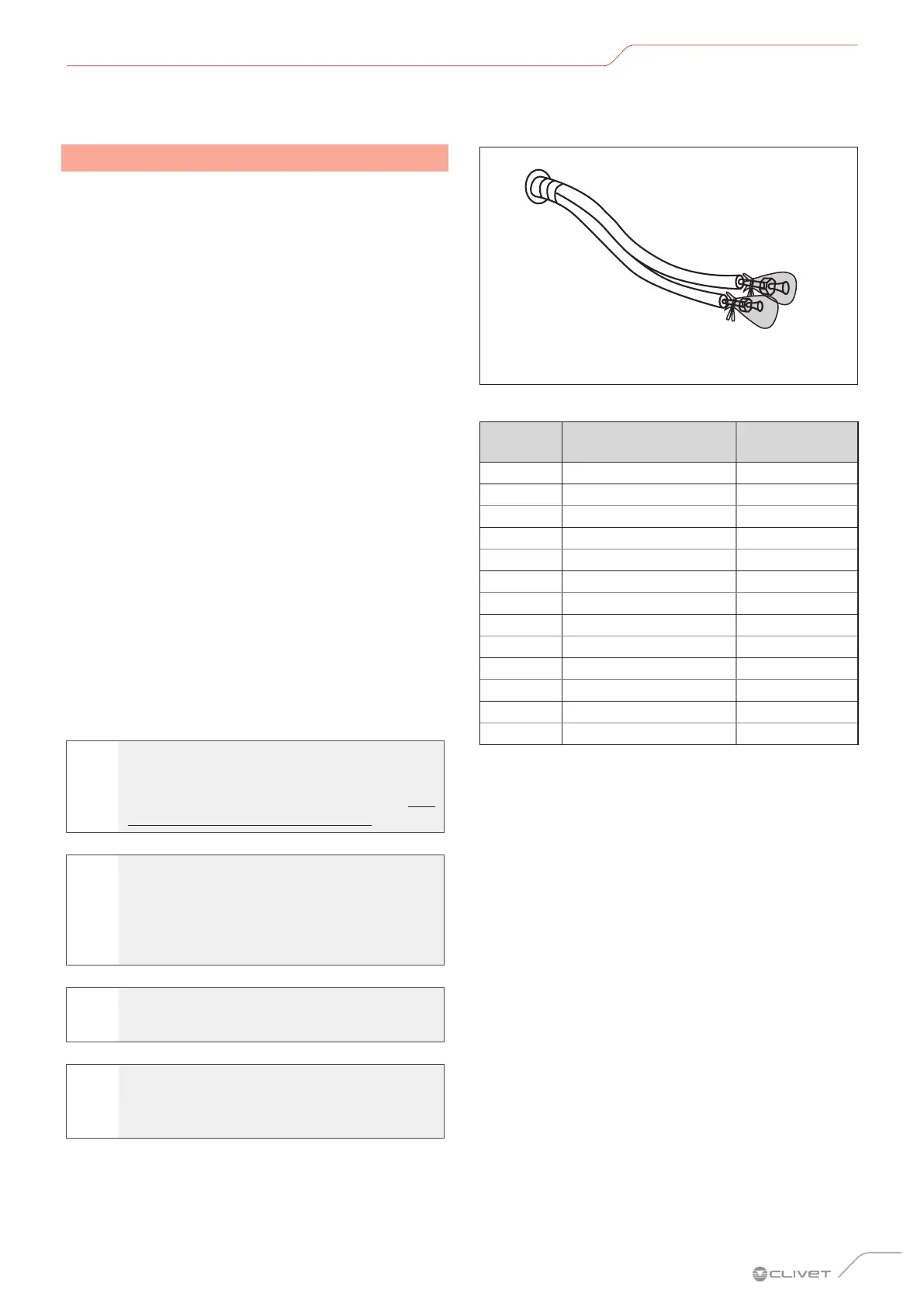

For the diameter to be used refer to the following table

Ø (mm) Ø (inches)

Radial

thickness (mm)

6.35 1/4” 0.8

9.52 3/8” 0.8

12.7 1/2” 0.8

15.9 5/8” 1.0

19.1 3/4” 1.0

22.2 7/8” 1.2

25.4 1” 1.2

28.6 1” - 1/8” 1.3

31.8 1” - 1/4” 1.5

38.1 1” - 3/8” 1.5

41.3 1” - 5/8” 1.5

44.5 1” - 3/4” 1.5

54.0 2” - 1/8” 1.8

Blow nitrogen through the sections pre-welded in the

workshop to expel any dust.

Pipes should only be cut using roller pipe cutters (do not

use a hacksaw).

Dirt that penetrates the pipes when in use could clog the

expansion valves, the capillaries or enter the compressor,

causing the latter to malfunction.

Loading...

Loading...