40

Starting up the system

Example:

Initial room temperature (Ti) after charging with N2: 26°C

Nitrogen pressure (Pi) in the system at 26°C: 4.0 MPa

(40bar)

Final room temperature (Tf) after 24 hours: 18°C

Nitrogen pressure (expected) at final room temperature

(Tf) after 24 hours:

= 40 bar + (18°C-26°C) x 0.1bar/°C

= 40 bar - 0.6 bar

Pf = 39.4 bar

If the actual final pressure (Pf) is evidently lower than the

expected final pressure (Pf) (< 39.4 bar), there is a leak

that needs to be found.

– Perform vacuum drying. See paragraph “6.3

Vacuum operation” page 40

If drying cannot be carried out immediately, reduce the

pressure to 0.5-0.8MPa until drying is possible.

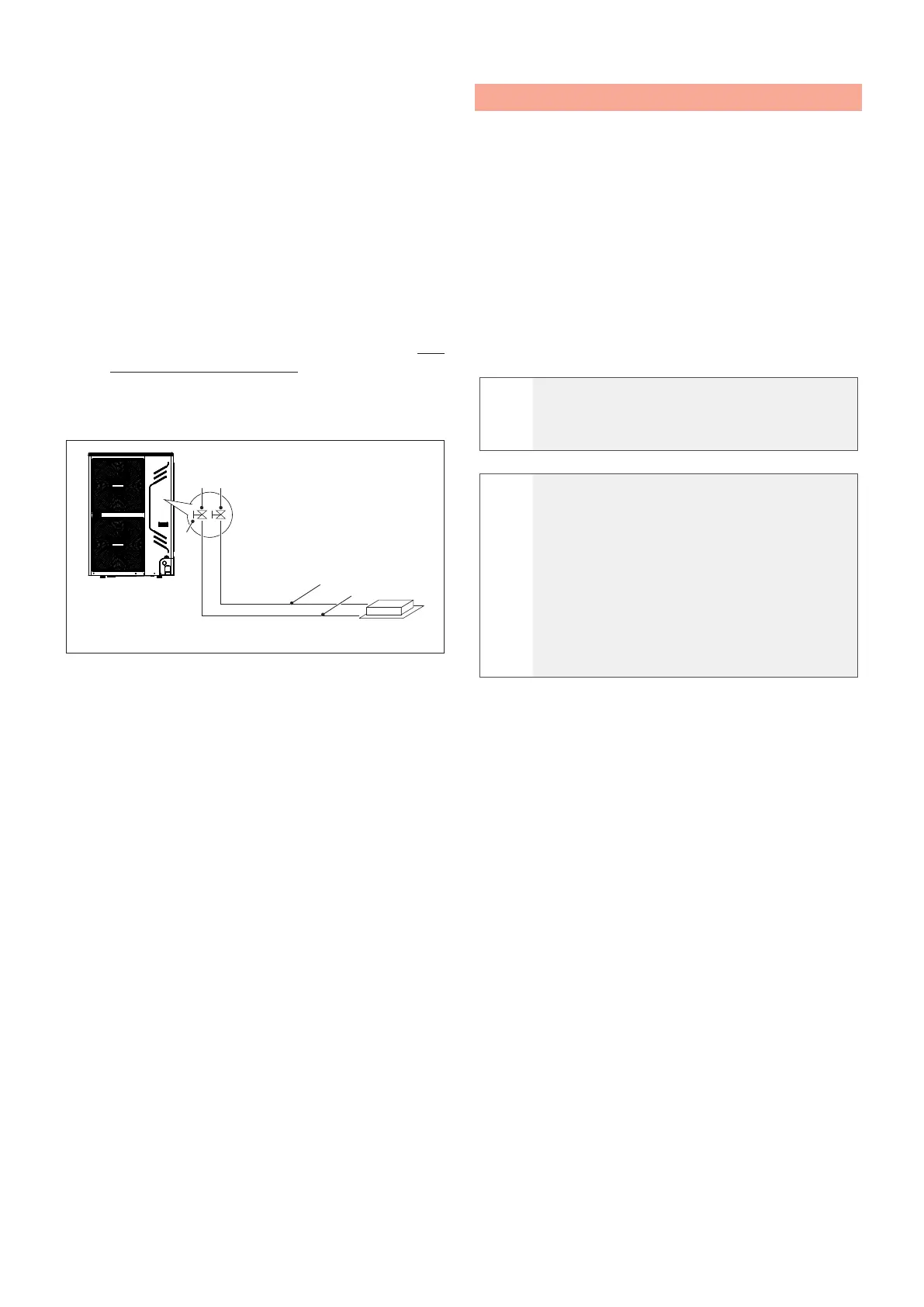

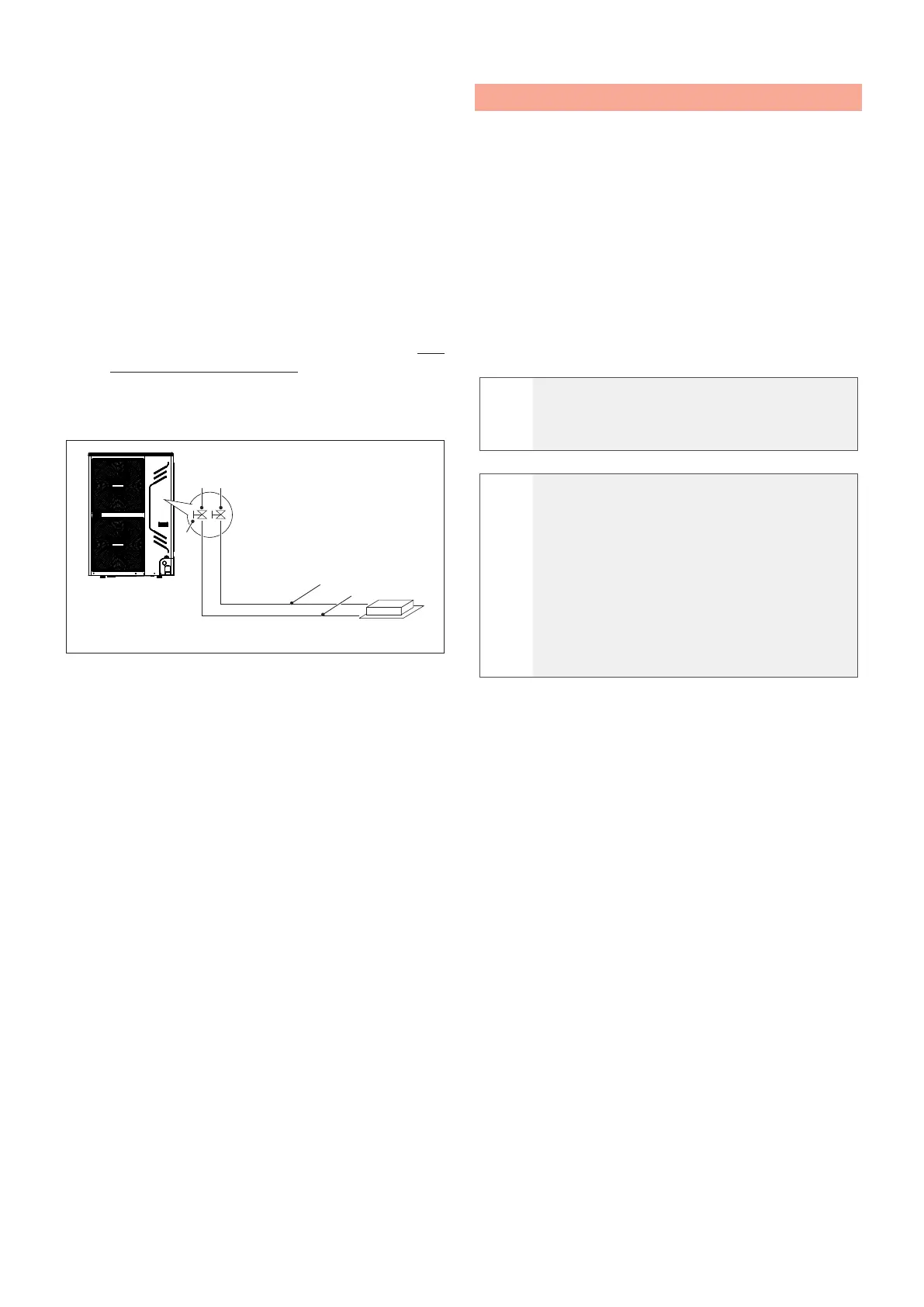

4

1

3

2

5

Fig. 64

In order to detect nitrogen leaks, proceed as follows:

– it is possible to hear a noise when there are

significant leaks;

– put your hands on the joints to feel for gas leaks;

– apply soapy water over the joints made. If bubbles

form, there are small leaks.

– check all the joints with a leak detector.

6.3 Vacuum operation

Perform drying to remove moisture and non-condensable

gases from the system. The elimination of moisture

prevents the formation of ice and the oxidation of copper

pipes or other internal components.

The presence of ice particles in the system could cause

malfunctions.

Oxidised copper particles can cause damage to the

compressor.

Non-condensable gases present in the system could

cause pressure fluctuations and lead to poor performance

of the heat exchanger.

The combination of a vacuum operation and a gas leak

test facilitates the detection of leaks.

m

CAUTION

Before vacuum drying, make sure that all the

stop valves of the outdoor unit are closed.

m

CAUTION

Use only one-way valves. Once the procedure

is complete and the pump stops, the low

pressure can draw the lubricant from the

pump into the system. The same situation

arises if the pump suddenly stops during the

procedure.

Mixing of the pump lubricant with the

compressor oil can cause the compressor to

malfunction.

To perform drying, a vacuum pump is used to lower

the pressure in the pipes until all the moisture present

evaporates.

It is necessary to use a vacuum pump capable of

maintaining a pressure

equal to or less than -756

mmHg (recommended vacuum level: <750mTorr) below

atmospheric pressure. At -755 mmHg below atmospheric

pressure, water reaches its boiling point at 0 °C.

We recommend using a vacuum pump with a discharge

rate greater than 4 litres/s and an accuracy level of 0.02

mmHg

To carry out the vacuum operation, proceed as follows:

– Connect a three-way pressure gauge (1) to the

gas pipe stop valve (2) of the main unit via the low

pressure pipe (B) and to the liquid pipe stop valve

(3) via the high pressure pipe (A) and to the vacuum

pump (4) via the vacuum refrigerant pipe (C).

Loading...

Loading...