10

HOWTOUSEYOURAIRCOMPRESSOR

See gures 5 - 6.

Do not allow familiarity with tools to make

you careless. Remember that a careless fraction of a second

is sufcient to inict serious injury.

Always wear safety goggles or safety

glasses with side shields when operating power tools. Failure

to do so could result in objects being thrown into your eyes

resulting in possible serious injury.

Do not use in an environment that is dusty or

otherwise contaminated. Using the air compressor in this type

of environment may cause damage to the unit.

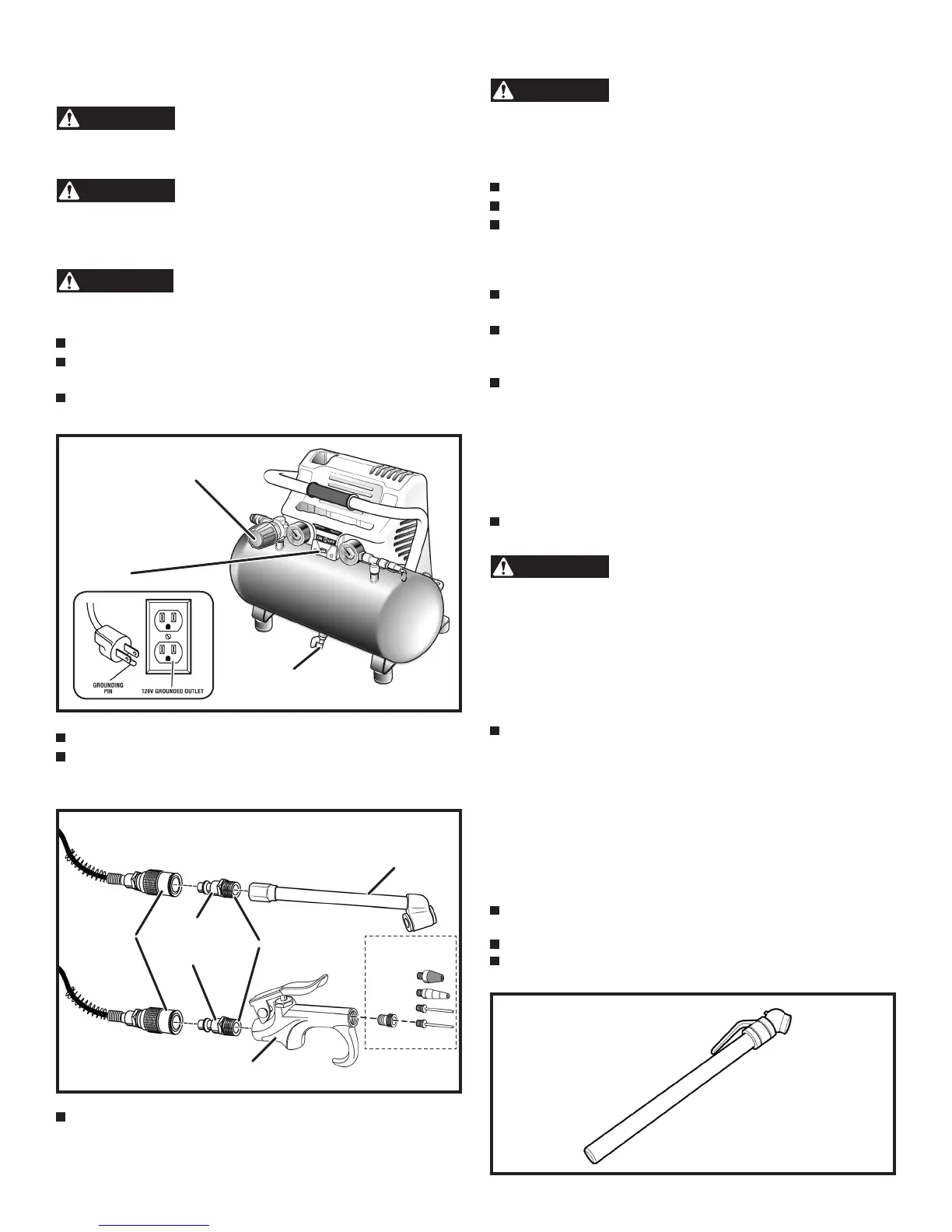

Ensure the tank drain valve is closed (see g. 5).

Ensure the ON/OFF switch is in the OFF(O) position and the

air compressor is unplugged (see g. 5).

Ensure the pressure regulator knob is turned fully

counterclockwise (see g. 5).

Always ensure the switch is in the OFF

(O) position and the regulator pressure gauge reads zero

before changing air tools or disconnecting the hose from the

air outlet. Failure to do so could result in possible serious

personal injury.

Connect the power cord to the power supply.

Turn the ON/OFF switch to the ON(I) position.

Rotate the pressure regulator knob to the desired line

pressure. Turning the knob clockwise increases air pressure

at the outlet; turning the knob counterclockwise reduces air

pressure at the outlet.

NOTE: Before connecting or disconnecting air tools, turn the

regulator knob counterclockwise to stop the ow of air.

Following all safety precautions in this manual and the

manufacturer’s instructions in the air tool manual. You may

now use your air-powered tool.

If using an ination accessory with a quick-connect tting,

control the amount of air ow with the pressure regulator knob.

Turning the knob fully counterclockwise will completely stop

the ow of air.

NOTE: Always use the minimum amount of pressure

necessary for your application. Using a higher pressure than

needed will drain air from the tank more rapidly and cause the

unit to cycle on more frequently.

When nished, always drain the tank and unplug the unit.

Never leave the unit plugged in and/or running unattended.

Check the air tool manual to insure the

correct air pressure regulator setting for optimum operation of

your air tools. If you are using an air tool not originally included

with the air tool kit supplied with this air compressor, your tool

may require more air consumption than this air compressor is

designed to supply.

Always read your air tool owner’s manual to match the correct

air supply to your air tool to avoid damage to the tool or risk of

personal injury.

NOTE: Do not exceed 50% duty cycle - 5 minutes ON and 5

minutes OFF.

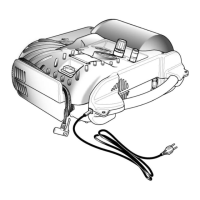

If not already installed, attach the hose to the compressor.

Apply thread sealing tape to male threaded end of the male

connector tting. Attach 1/4 in. NPT male connector tting to

accessory or tool you intend to use (see g. 6).

Drain

valve

Pressure

regulatorknob

On/Off

switch

Fig. 5

Coil hose

withquick

coupler

attached

1/4in.male

connector

fitting

Blow gun

Thread

sealing

tape

Longination

chuck

Fig. 6

Inflation

accessories

Connect the air powered tools to the air hose by inserting the

male quick-connect plug to the quick-coupler at the end of the

hose (see g. 6).

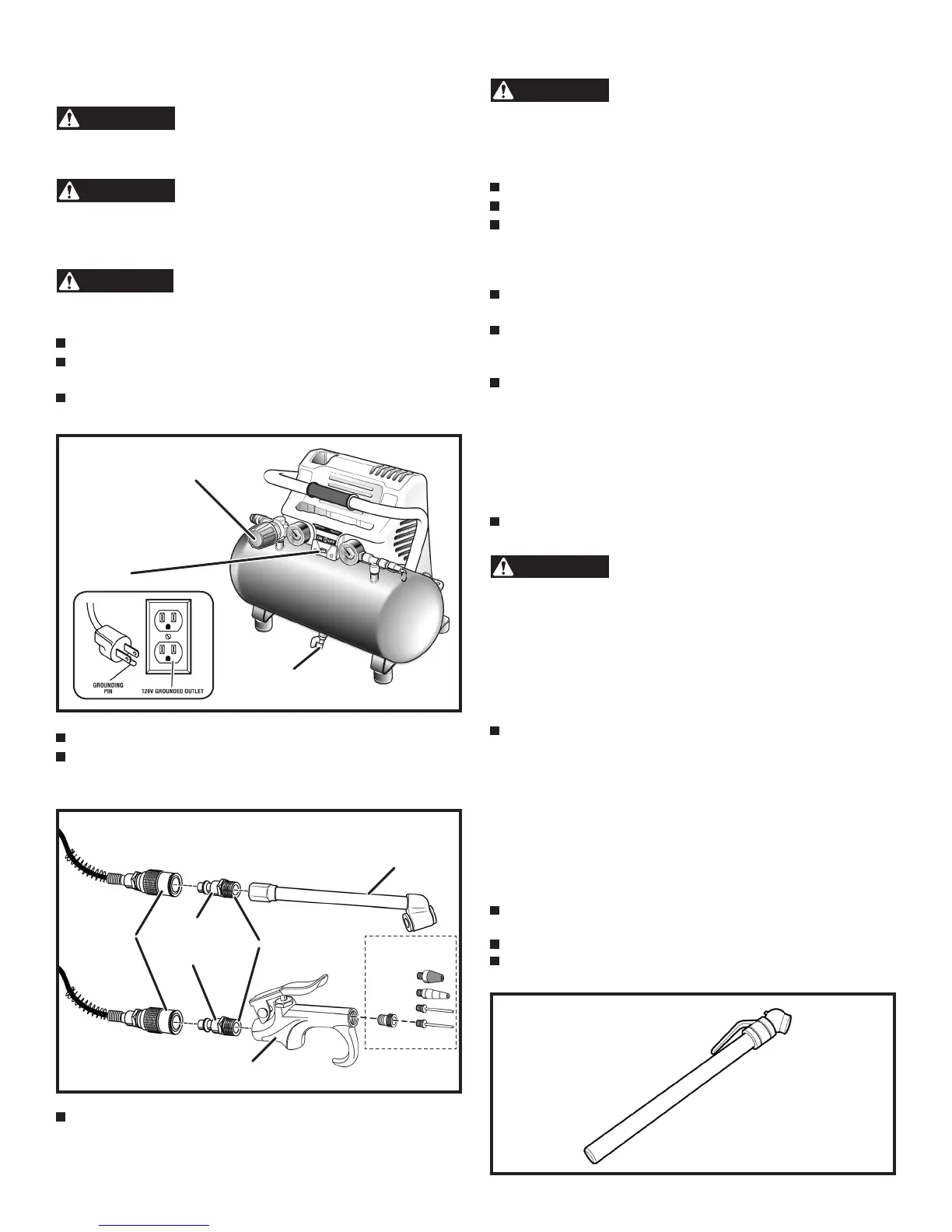

TIREGAUGE(see gure 7)

Operating instructions:

1. Press gauge rmly onto valve stem.

2. Read PSI on indicator bar.

3. Adjust pressure to manufacturer’s specications.

4. Push indicator bar back into gauge.

Always keep your tires inated to manufacturer’s

recommended pressure.

Check pressure when tire is cold.

Proper ination helps prevent blowouts, increases gas mileage

and prolongs tire life.

Fig. 7

Loading...

Loading...