WARNING: FOR YOUR OWN SAFETY ALWAYS

LOCK THE SWITCH "OFF" WHEN SAW IS NOT

IN USE. REMOVE KEY AND KEEP IT IN A SAFE

PLACE . . . ALSO IN THE EVENT OF A POWER

FAILURE (ALL YOUR LIGHTS GO OUT) TURN

SWITCH OFF. LOCK IT AND REMOVE THE KEY

THIS WILL PREVENT THE SAW FROM

STARTING UP AGAIN WHEN THE POWER

COMES BACK ON.

7. The Manual Motor Brake.

a. The manual brake is located on the motor shaft at

the right-hand end of motor.

la. Pressing on the brake button with finger or thumb,

after turning off the ON-OFF switch, will greatly

reduce blade coasting time.

8. Accessory Shaft.

NOTE: When using an accessory such as a drill chuck

attached to end of motor shaft, it will be necessary to

remove the accessory shaft cover.

CAUTION: Motor spacer, both blade collars and shaft nut

must be installed when using accessory shaft.

Be sure to re-install the accessory shaft cover

after removing the accessory.

Use only the following recommended accessories:

Drill chuck, Sanding drum, and Router adapter.

CAUTION: The sawblade, dado, or cutting tool must

be removed from the saw arbor before using the

accessory shaft. NEVER operate the saw with cutting

tools (including sanding accessories) installed on both

ends of the saw arbor.

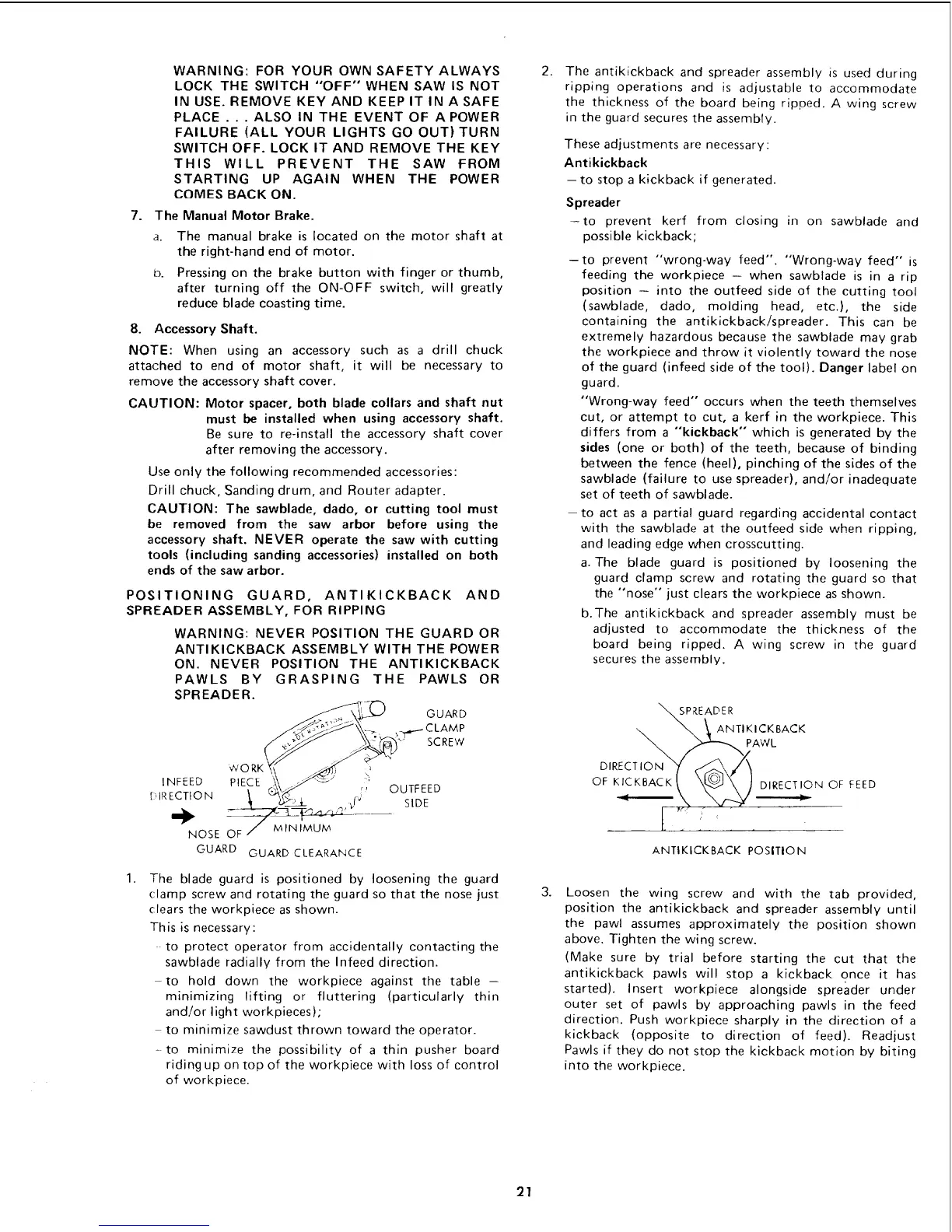

POSITIONING GUARD, ANTIKICKBACK AND

SPREADER ASSEMBLY, FOR RIPPING

WARNING: NEVER POSITION THE GUARD OR

ANTIKICKBACK ASSEMBLY WITH THE POWER

ON. NEVER POSITION THE ANTIKICKBACK

PAWLS BY GRASPING THE PAWLS OR

SPREADER.

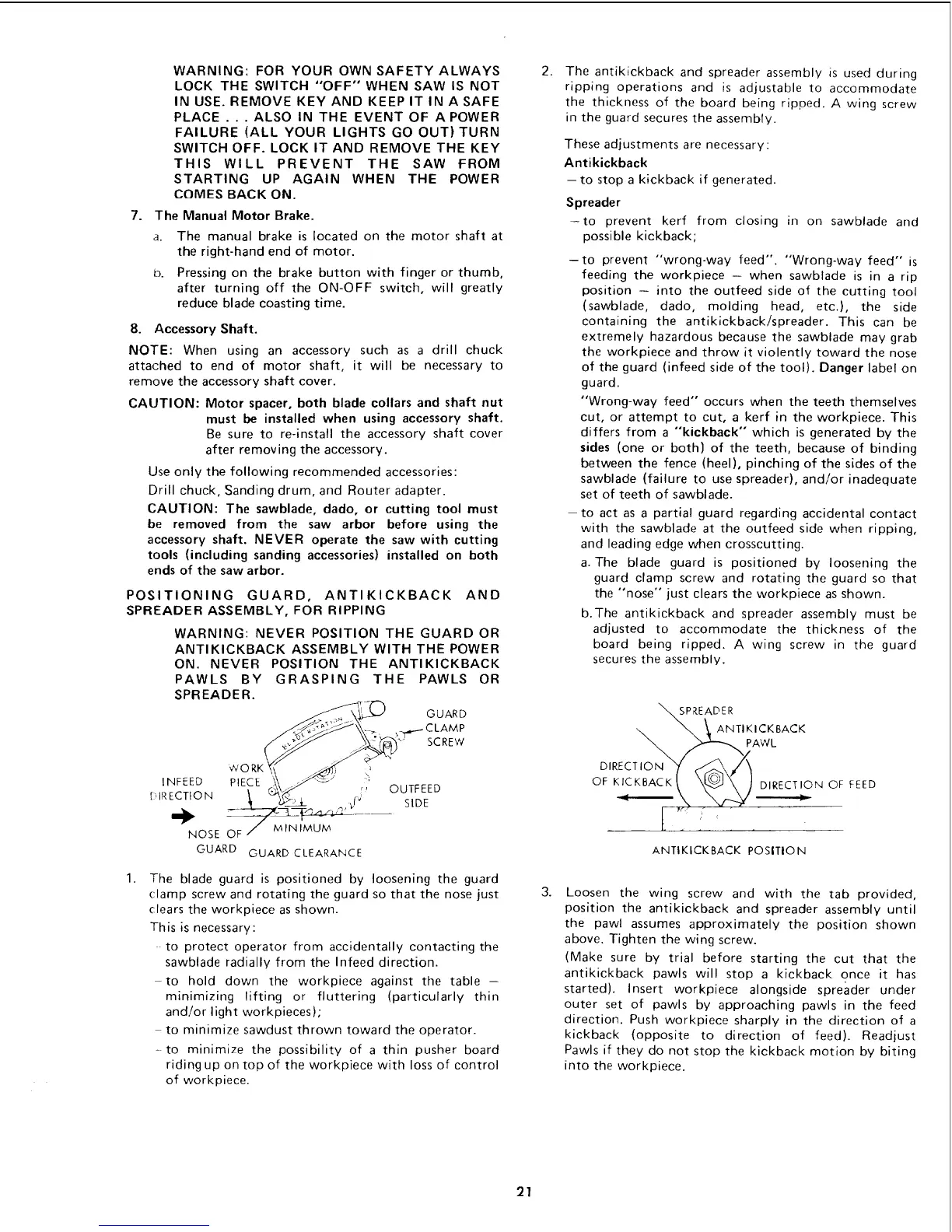

_) GUARD

'NFEED _l EO_K __ O UsTFEEED

DIRECTION

NOSE OF J MINIMUM

GUARD GUARD CLEARANCE

1.

The blade guard is positioned by loosening the guard

clamp screw and rotating the guard so that the nose just

clears the workpiece as shown.

This is necessary:

to protect operator from accidentally contacting the

sawblade radially from the Infeed direction.

to hold down the workpiece against the table -

minimizing lifting or fluttering (particularly thin

and/or light workpieces);

to minimize sawdust thrown toward the operator.

- to minimize the possibility of a thin pusher board

riding up on top of the workpiece with loss of control

of workpiece.

2.

The antikickback and spreader assembly is used during

ripping operations and is adjustable to accommodate

the thickness of the board being ripped. A wing screw

in the guard secures the assembly.

These adjustments are necessary:

Antikickback

-- to stop a kickback if generated.

Spreader

-to prevent kerf from closing in on sawblade and

possible kickback;

-to prevent "wrong-way feed". "Wrong-way feed" is

feeding the workpiece -- when sawblade is in a rip

position -- into the outfeed side of the cutting tool

(sawblade, dado, molding head, etc.), the side

containing the antikickback/spreader. This can be

extremely hazardous because the sawblade may grab

the workpiece and throw it violently toward the nose

of the guard (infeed side of the tool). Danger label on

guard.

"Wrong-way feed" occurs when the teeth themselves

cut, or attempt to cut, a kerf in the workpiece. This

differs from a "kickback" which is generated by the

sides (one or both) of the teeth, because of binding

between the fence (heel), pinching of the sides of the

sawblade (failure to use spreader), and/or inadequate

set of teeth of sawblade.

-to act as a partial guard regarding accidental contact

with the sawblade at the outfeed side when ripping,

and leading edge when crosscutting.

a. The blade guard is positioned by loosening the

guard clamp screw and rotating the guard so that

the "nose" just clears the workpiece as shown.

b.The antikickback and spreader assembly must be

adjusted to accommodate the thickness of the

board being ripped. A wing screw in the guard

secures the assembly.

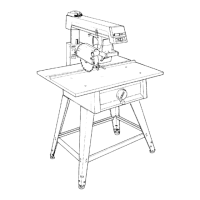

DIRECT%

OF KICKBACK

SPREADER

ANTIKICKBACK

PAWL

DIRECTION OF FEED

ANTIKICKBACK POSITIO N

3.

Loosen the wing screw and with the tab provided,

position the antikickback and spreader assembly until

the pawl assumes approximately the position shown

above. Tighten the wing screw.

(Make sure by trial before starting the cut that the

antikickback pawls will stop a kickback once it has

started). Insert workpiece alongside spreader under

outer set of pawls by approaching pawls in the feed

direction. Push workpiece sharply in the direction of a

kickback (opposite to direction of feed). Readjust

Pawls if they do not stop the kickback motion by biting

into the workpiece.

21

Loading...

Loading...