maintenance and lubrication

MAINTENANCE

WARNING: FOR YOUR OWN SAFETY, TURN SWITCH

"OFF" AND REMOVE PLUG FROM POWER SOURCE

OUTLET BEFORE MAINTAINING OR LUBRICATING

YOUR SAW.

When you receive your new Craftsman radial saw, it

requires no lubrication. The radial saw has been partially

aligned and all bearings are lubricated and sealed for life. In

time, however, in order to keep your saw in perfect

working order and accurate, it will be necessary to lubricate

and realign. In fact, your radial saw needs more of a

cleaning than a lubrication.

Make sure the teeth of the ANTI KICKBACK pawls are

always sharp. Replace if not sharp.

LUBRICATION

Your saw is precision built and should be kept clean and

properly lubricated. Before describing the various points

which may periodically require lubrication, IT IS MORE

IMPORTANT TO FIRST MENTION THE VARIOUS

POINTS WHICH SHOULD NOT BE LUBRICATED.

NO LUBRICATION REQUIRED

Do not lubricate carriage ball bearings or motor bearings as

these are sealed ball bearings and require no added

lubrication.

PERIODICALLY LUBRICATE THESE POINTS

Use SAE No. 10W-30 automotive engine oil and refer to

Parts List for locations. Apply a few drops of oil along the

swivel latch pin and bevel index pin only if the pin has a

tendency to stick. Remove the left-hand carriage cover and

use oil sparingly to prevent it from getting on the ball

bearings or races.

A light film of oil should be wiped on the face of the

column tube to lubricate the fit between the column tube,

and column support.

CAUTION: Excessive oil at any location will attract

airborne dust particles and sawdust.

I

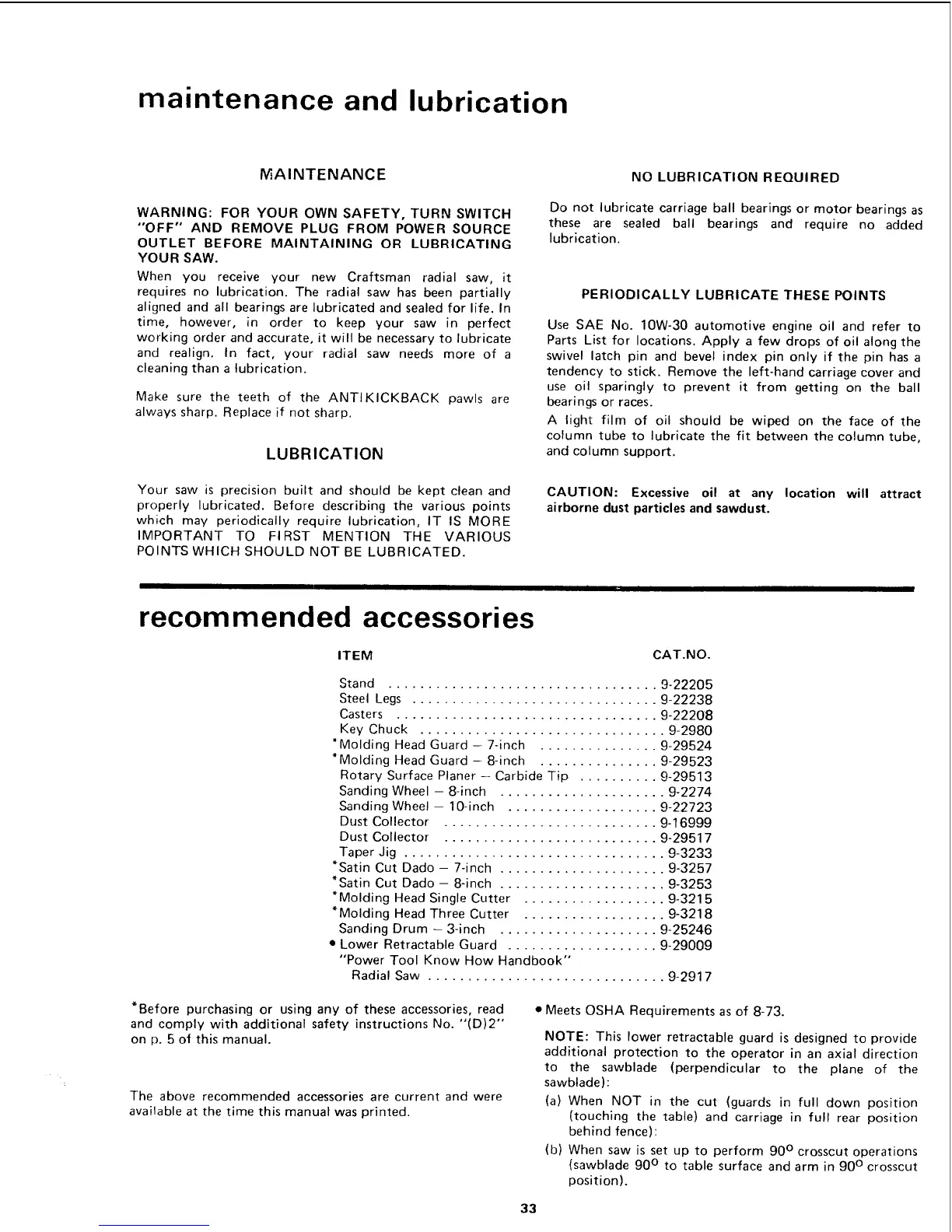

recommended accessories

ITEM CAT.NO.

Stand .................................. 9-22205

Steel Legs ............................... 9-22238

Casters ................................. 9-2220'8

Key Chuck ............................... 9-2980

*Molding Head Guard - 7-inch ............... 9-29524

*Molding Head Guard - 8-inch ............... 9-29523

Rotary Surface Planer - Carbide Tip .......... 9-29513

Sanding Wheel - 8-inch ..................... 9-2274

Sanding Wheel - 10-inch ................... 9-22723

Dust Collector ........................... 9-16999

Dust Collector ........................... 9-29517

Taper Jig ................................. 9-3233

*Satin Cut Dado - 7-inch ..................... 9-3257

*Satin Cut Dado - 8-inch ..................... 9-3253

*Molding Head Single Cutter .................. 9-3215

*Molding Head Three Cutter .................. 9-3218

Sanding Drum - 3-inch .................... 9-25246

• Lower Retractable Guard ................... 9-29009

"Power Tool Know How Handbook"

Radial Saw .............................. 9-2917

*Before purchasing or using any of these accessories, read

and comply with additional safety instructions No. "(D)2"

on p. 5 of this manual.

The above recommended accessories are current and were

available at the time this manual was printed.

• Meets OSHA Requirements as of 8-73.

NOTE: This lower retractable guard is designed to provide

additional protection to the operator in an axial direction

to the sawblade (perpendicular to the plane of the

sawblade):

(a) When NOT in the cut (guards in full clown position

(touching the table) and carriage in full rear position

behind fence):

(b) When saw is set up to perform 90 ° crosscut operations

(sawblade 90 ° to table surface and arm in 90 ° crosscut

position).

33

Loading...

Loading...