ERVICE AND ADJUSTMENTS

i,

ENGINE

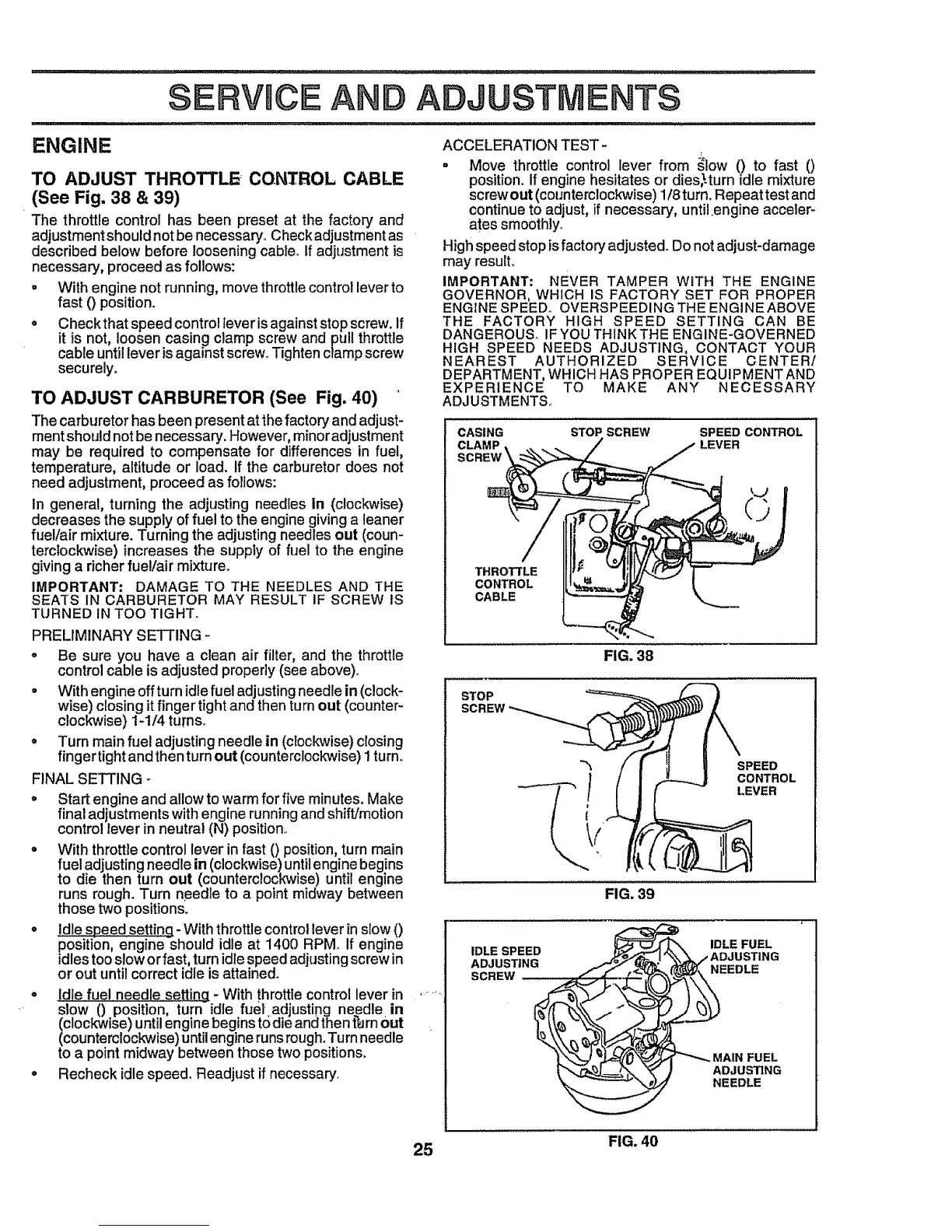

TO ADJUST THROTTLE CONTROL CABLE

(See Fig, 38 & 39)

The throttle control has been preset at the factory and

adjustmentshould not be necessary. Checkadjustment as

described below before loosening cable° If adjustment is

necessary, proceed as follows:

° With engine not running, move throttlecontrol leverto

fast 0 position.

o Checkthat speed controllever isagainststopscrew. If

it is not, loosen casing clamp screw and pull throttle

cable untillever isagainst screw° Tightenclampscrew

securely.

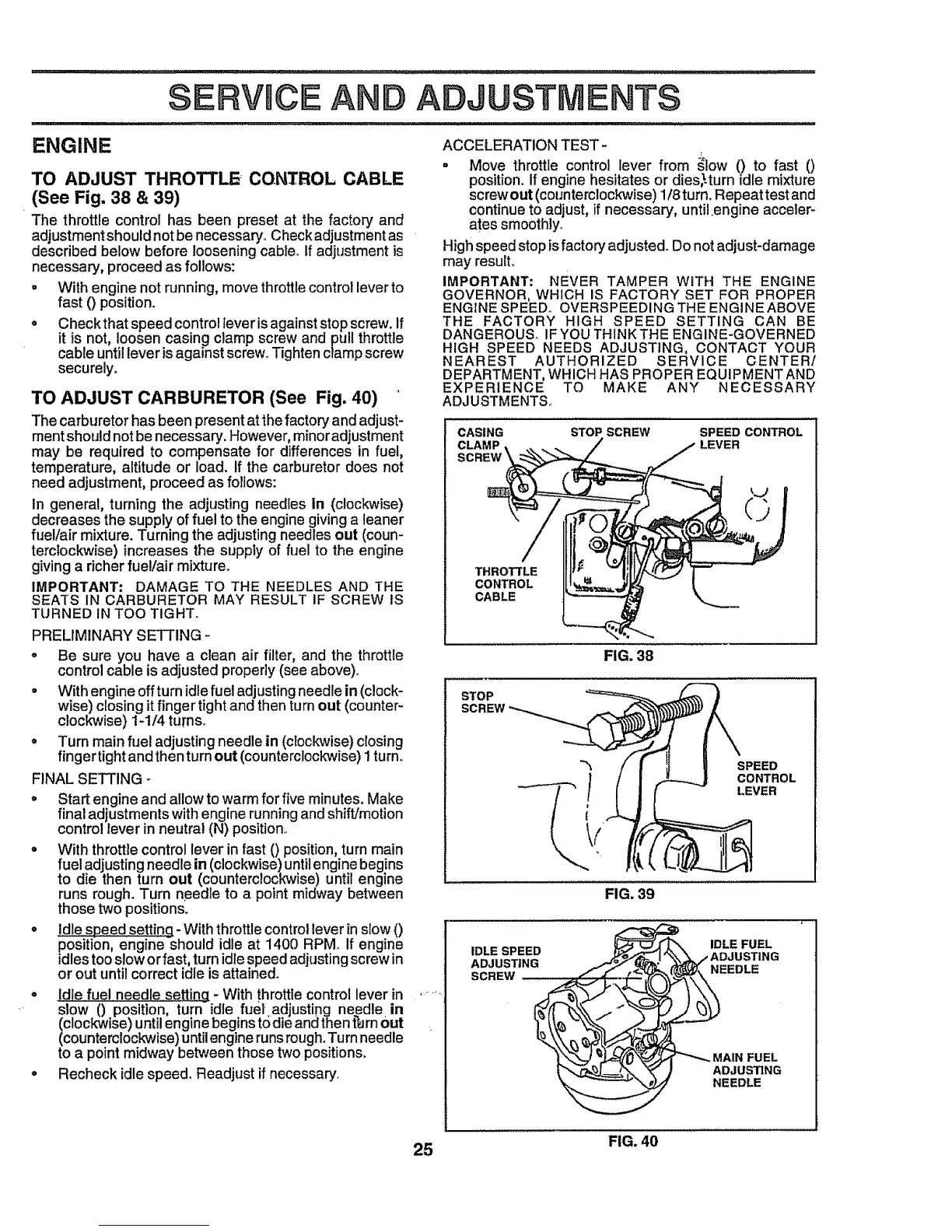

TO ADJUST CARBURETOR (See Fig. 40)

The carburetor has been present at the factory and adjust-

rnentshould notbe necessary. However,minoradjustment

may be required to compensate for differences in fuel,

temperature, altitude or load. If the carburetor does not

need adjustment, proceed as follows:

In general, turning the adjusting needles in (clockwise)

decreases the supply of fuel to the engine giving a ieaner

fuel/air mixture. Turning the adjusting needles out (coun-

terclockwise) increases the supply of fuel to the engine

givinga richer fue!/air mixture°

IMPORTANT: DAMAGE TO THE NEEDLES AND THE

SEATS IN CARBURETOR MAY RESULT IF SCREW tS

TURNED IN TOO TIGHT°

PRELIMINARY SETTING -

o Be sure you have a clean air filter, and the throttle

control cable is adjusted properly (see above),,

. With engine off turn idle fuel adjusting needle in (clock-

wise) closing it finger tight and then turn out (counter-

clockwise) 1-1/4 turns,,

° Turn main fuel adjusting needle in (clockwise) closing

finger tight and then turn out (counterclockwise) 1turn,,

FINAL SETTING -

° Start engine and allow to warm for five minutes. Make

final adjustments with engine running and shift/motion

control lever in neutral (N) position,,

. With throttle control lever in fast 0 position, turn main

fuel adjusting needlein (clockwise) untilengine begins

to die then turn out (counterclockwise) until engine

runs rough. Turn needle to a point midway between

those two positions.

° Idle sneed settina- With throttle control lever in slow 0

position, engine'should idle at 1400 RPM if engine

idles too slow or fast, turn idle speed adjusting screw in

or out until correct idle is attained°

° idle fuel needle setting - With throttle control lever in

slow () position, turn idle fuel' adjusting needle in

(clockwise) until engine begins to die and then tfamout

(counterclockwise) until engine runsrough. Turn needle

to a point midway between those two positions.

° Recheck idle speed. Readjust if necessary.

ACCELERATION TEST -

= Move throttle control lever from _low 0 to fast 0

position, If engine hesitates or dies,_.turn Idle mixture

screw out (counterclockwise) 1/8 turn, Repeat test and

continue to adjust, if necessary, until:engine acceler-

ates smoothly..

High speed stop is factory adjusted. Do not adjust-damage

may result.

IMPORTANT; NEVER TAMPER WITH THE ENGINE

GOVERNOR, WHICH IS FACTORY SET FOR PROPER

ENGINE SPEED. OVERSPEEDING THE ENGINE ABOVE

THE FACTORY HIGH SPEED SETTING CAN BE

DANGEROUS° IFYOU THINKTHE ENGINE-GOVERNED

HiGH SPEED NEEDS ADJUSTING, CONTACT YOUR

NEAREST AUTHORIZED SERVICE CENTER/

DEPARTMENT, WHICH HAS PROPER EQUIPMENT AND

EXPERIENCE TO MAKE ANY NECESSARY

ADJUSTMENTS..

CASING STOP SCREW SPEED CONTROL

LEVER

THROTTLE

CONTROL

CABLE

FIG. 38

STOP

SCREW

SPEED

CONTROL

LEVER

FIG. 39

.........

o _ _ ADJUSTING

....

_ ADJUSTING

NEEDLE

25 FIG. 40

Loading...

Loading...