39

Maintenance

Troubleshooting

When an alarm is activated

An alarm is generated when a defect that disables the continuance of operation is generated in OILCON.

To cancel the alarm, turn OFF the power supply, and then turn it ON again.

Alarm list

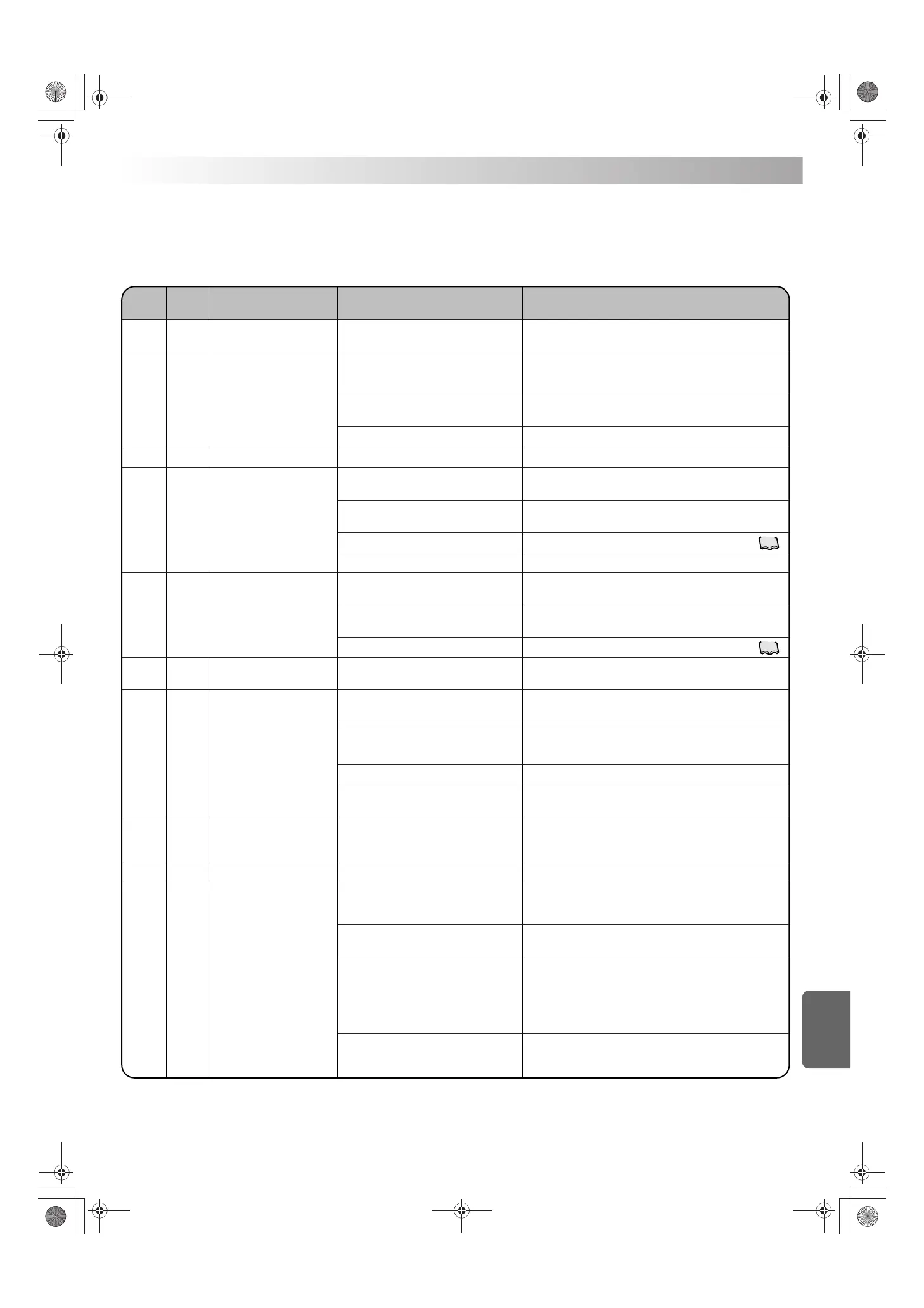

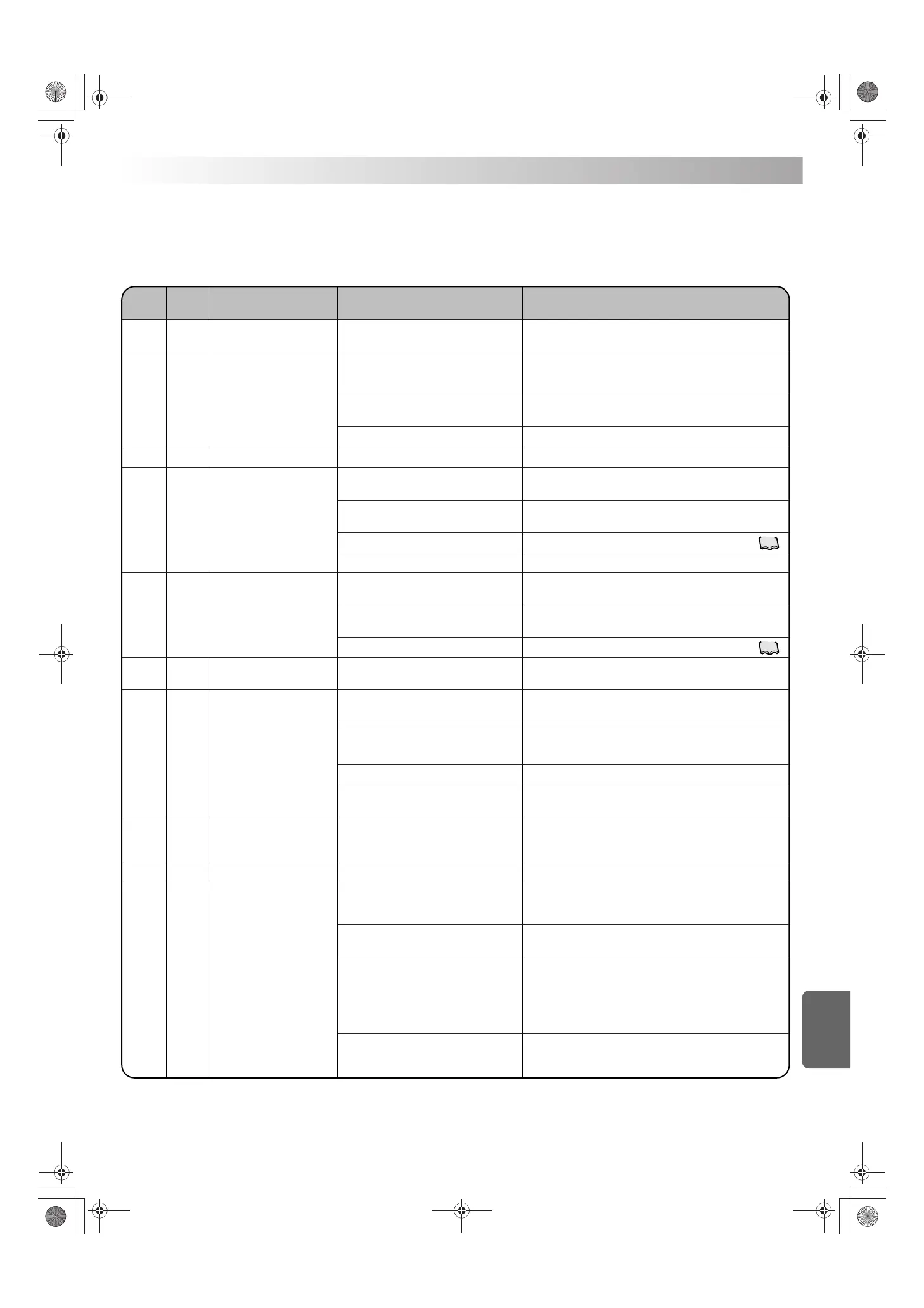

Alarm

code

Alarm∗

level

Description Cause Corrective action

Heater overheat (S4B1:S184)

(-H model only)

DC fan motor lock error

High pressure error

Compressor high temperature

error

Compressor (M2C) lock

System error

∗Alarm level 1: Compressor, pump and fan stop.

Alarm level 2: Only compressor stops.

Pump over-current relay

(K1S:S182) is activated.

AKZ149, 329, 439: 2.5A

Optional protection device is

activated. (OP.)

Pump outlet oil temperature error (Th10)

Inlet oil temperature is higher

than 60˚C.

AA 2

A6 2

E1 1

E3 2

E5 2

E6 2

EH 1

EJ 1 or 2

FE 1

FH 2

1) AKZ type:

No oil flow

1) Internal parameter setting is invalid.

3)

The air filter is clogged, or the condenser is dirty.

4) Any factor other than the above

3)

The air filter is clogged, or the condenser is dirty.

3)

The pump motor wiring has a break. (Open-phase)

1)

The pump outlet oil temperature is higher than 65˚C.

1) The oil temperature or room temperature

is higher than the specified range.

2) There is an obstacle near the air

intake/exhaust port.

1) The oil temperature or room temperature

is higher than the specified range.

2)

There is an obstacle near the air intake/

exhaust port.

1) Fault of the compressor

(Replace the compressor.)

1)

The pump is overloaded with high-viscosity

oil.

4) A foreign object is caught in the pump, or

the pump motor has a fault.

2)

There is an obstacle near the air intake/exhaust

port, resulting in cooling capacity deterioration.

2) Because the power supply voltage falls

below the operating range, the pump

current has increased.

1)

The optionally-connected protection device

(or factory-connected device, if it is

incorporated in the unit) has been activated.

1)

The heating value of the main machine has

exceeded the cooling capacity of the Oil

Cooling Unit. (Improper model selection)

Check if the oil circuit is properly connected and the pump

normally operates.

3) Fault of the DC fan motor Replace the DC fan motor.

Do not place any object that blocks ventilation at 500 mm or

shorter distance from the air intake/exhaust port.

Do not place any object that blocks ventilation at 500 mm or

shorter distance from the air intake/exhaust port.

Check if the power supply voltage is not lower than the

specified operating range. Check for an instantaneous power

supply voltage drop at startup of peripheral equipment.

If the unit is properly installed and the compressor runs at

100% capacity (capacity setting can be checked in the monitor

mode), select a model that provides larger cooling capacity.

Do not place any object that blocks ventilation at 500 mm or

shorter distance from the air intake/exhaust port.

Use an operating fluid that provides 1.4 to 200 mm

2

/s viscosity

in the specified oil temperature range.

Check the condition detected with the relevant protection device.

Check if the oil piping system is not blocked (fully closed).

Clean the air filter. (See “Maintenance/Inspection” on page .)

2) Fan motor-control board communication

error

1) Rotation speed of fan motor is insufficient

because of drop of DC voltage by break-

ing wire or looseness of connector.

Check the connector insertion and wire break.

Replace the control board.

Check the insertion and breaking of the signal wire and engine

wire between the filter board and the inverter board.

Replace the control board.

Use the unit within the specified operating range.

Contact DAIKIN Contact Center.

Use the unit within the specified operating range.

Replace the compressor.

Replace the pump motor.

Replace the pump motor.

37

Clean the air filter. (See “Maintenance/Inspection” on page .)

37

3)

The unit is running under capacity

suppressing control, because the standard

temperature (room temperature: 35˚C, oil

temperature: 35˚C) has been exceeded.

If the standard temperature is exceeded, the cooling capacity

becomes smaller than the nominal capacity, because the unit

runs under capacity suppressing control.

Make sure that the cooling capacity of the Oil Cooling Unit is

larger than the main machine heating value throughout the oper-

ating temperature range.

4) Temperature control is disabled because

the unit is operated in Mode 9 (capacity

direct designation mode).

Select an appropriate operation mode.

(The capacity direct designation mode does not execute temper-

ature feedback control.)

PIM00318A_EN.fm Page 39 Tuesday, October 26, 2010 12:37 PM

Loading...

Loading...