NO

YES

YES

YES

NO

NO

YES

NO

YES

NO

+5V

(4)

(3)

(2)

(1)

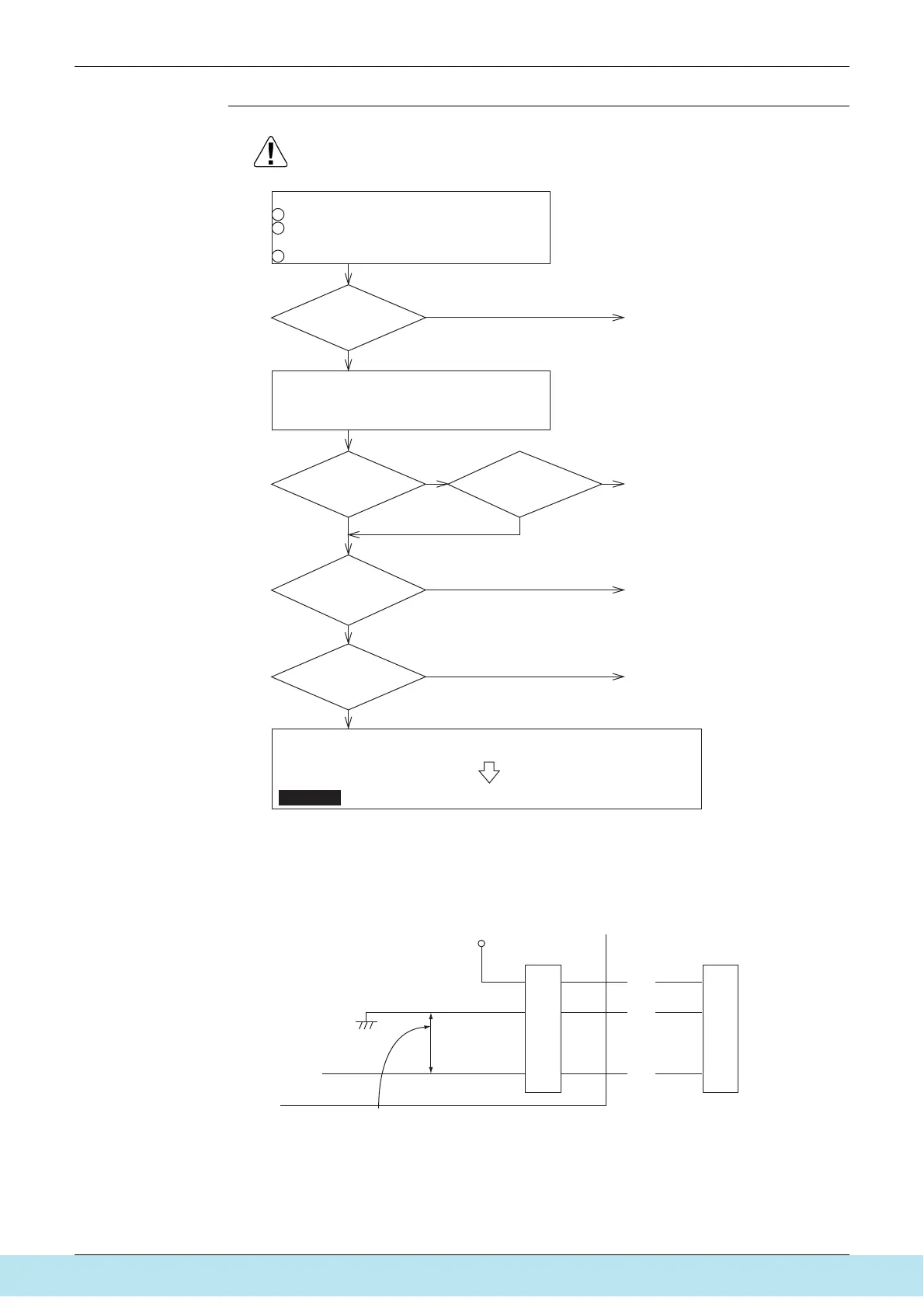

Check for the points shown below.

1 Is the stop valve open?

2 Is the HPS connector properly connected to the

main PC board?

3 Does the high pressure switch have continuity?

Are the

three points above

OK?

Rectify defective points, if any.

·

Mount a pressure gauge on the high-pressure service port.

· Connect the Service Checker.

· Reset the operation using the remote controller,

and then restart the operation.

Does the stop

due to malfunction (E3)

recur?

Is the HPS

operating value normal

(i.e., 4.0MPa)?

Are the

characteristics of the high

pressure sensor normal?

(See *1.)

Replace the HPS.

Replace the high pressure sensor.

Is the

pressure detected with

the PC board normal?

(See *2.)

Replace the main PC board.

· The high pressure sensor is normal, and the pressure detected with the PC board is also normal.

· The high pressure has really become high.

CHECK 1

Refer to information on P.223, remove the causes by

which the high pressure has become high.

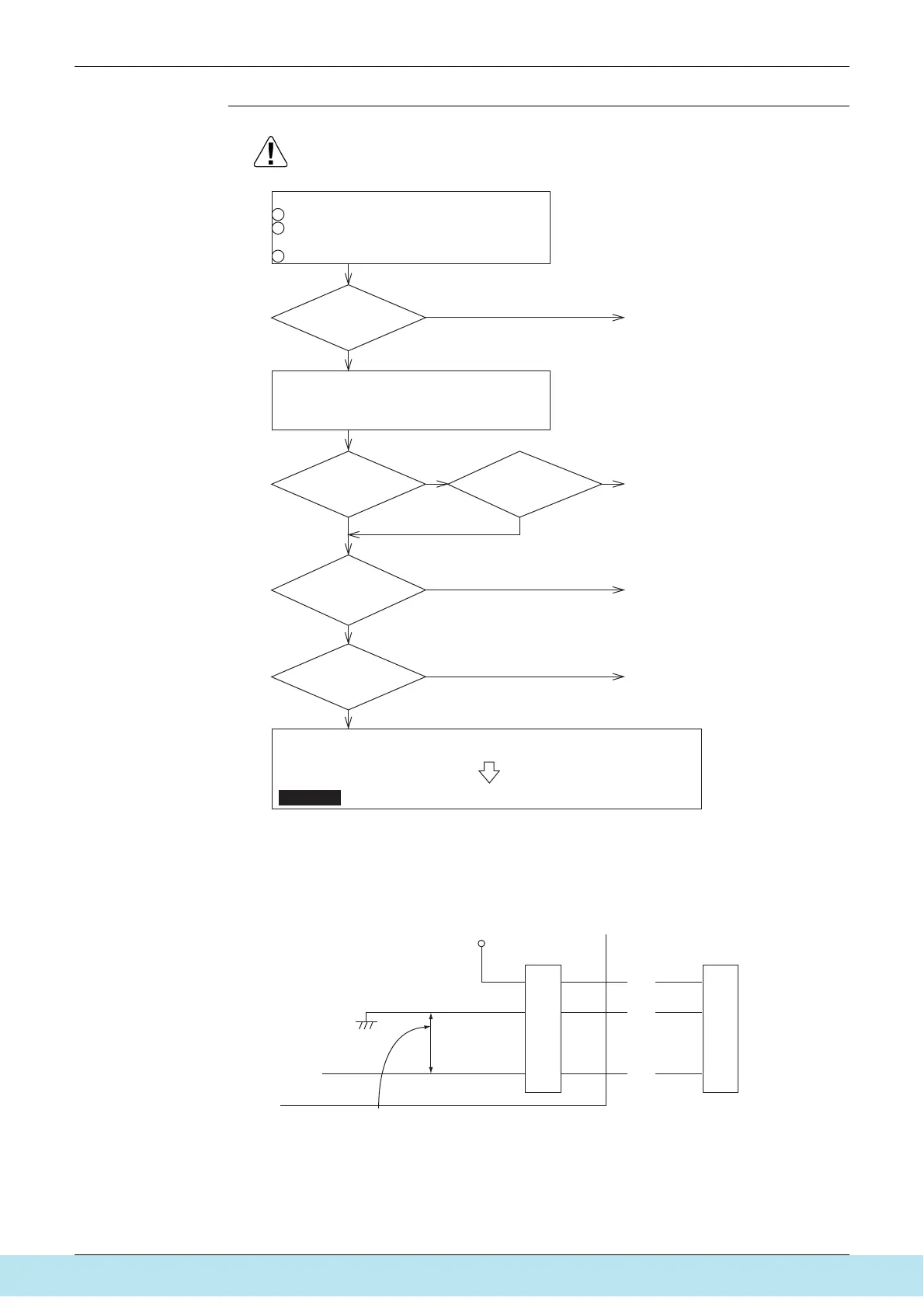

*1: Make a comparison between the voltage of the pressure sensor (*4) and that read by the

pressure gauge.

(As to the voltage of the pressure sensor, make measurement of voltage at the connector, and

then convert it to pressure according to information on “Pressure Sensor”.)

*2: Make a comparison between the high pressure value checked with the Service Checker and the

voltage of the pressure sensor (see *1).

*3: Make measurement of voltage of the pressure sensor.

Connector for high

pressure sensor (Red)

High

pressure

sensor

Micro controller

A/D input

Make measurement of DC voltage between these wires. (*4)

Red

Black

White

Caution

Be sure to turn off power switch before connect or disconnect connector,

or parts damage may be occurred.

Loading...

Loading...