8 | RS8EU702 |

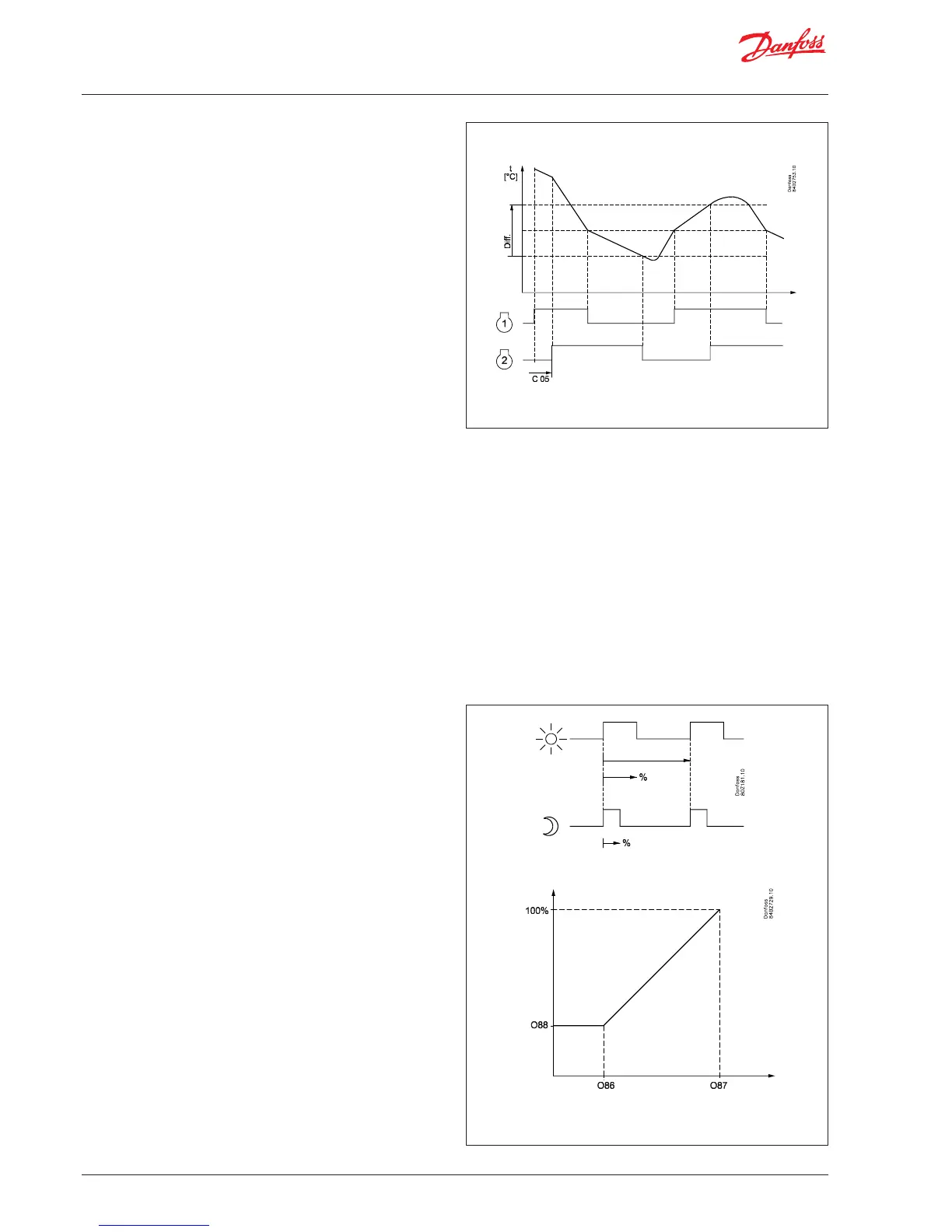

Control of two compressors

General:

The two compressors must be of a type that can start up against a

high pressure.

The running compressor will continue until the temperature has

reached the cutout value. Then it will cut out. When the tempera-

ture again reaches the middle of the dierential, a compressor will

again be started.

If one compressor cannot maintain the temperature within the

dierential, the second compressor will also be started.

The compressor's settings for ”Min On time” and ”Min O time”

will always have top priority during normal regulation. But if one

of the override functions is activated, the ”Min On time” will be

disregarded.

Cyclical operation:

The two compressors must be of the same size.

When the controller demands refrigeration it will rst cut in the

compressor with the shortest operating time.

After the time delay the second compressor will be cut in.

When the temperature has dropped to ”the middle of the dieren-

tial”, the compressor with the longest operation time will be cut

out.

If one of the compressors has run on its own for two hours, the

compressors will be changed over so that operational time is bal-

anced.

Sequential operation:

Here, compressor 1 will start as the rst one, and, when needed,

compressor 2 will be started.

Determined by thermostat band:

The compressor operating mode can be set in application 9 so

that both compressors run sequentially in thermostat band 1, but

compressor 2 is not permitted in thermostat band 2.

Railheat

It is possible to pulse-control the power to the rail heat in order to

save energy. Pulse control can either be controlled according to

day/night load or dew point.

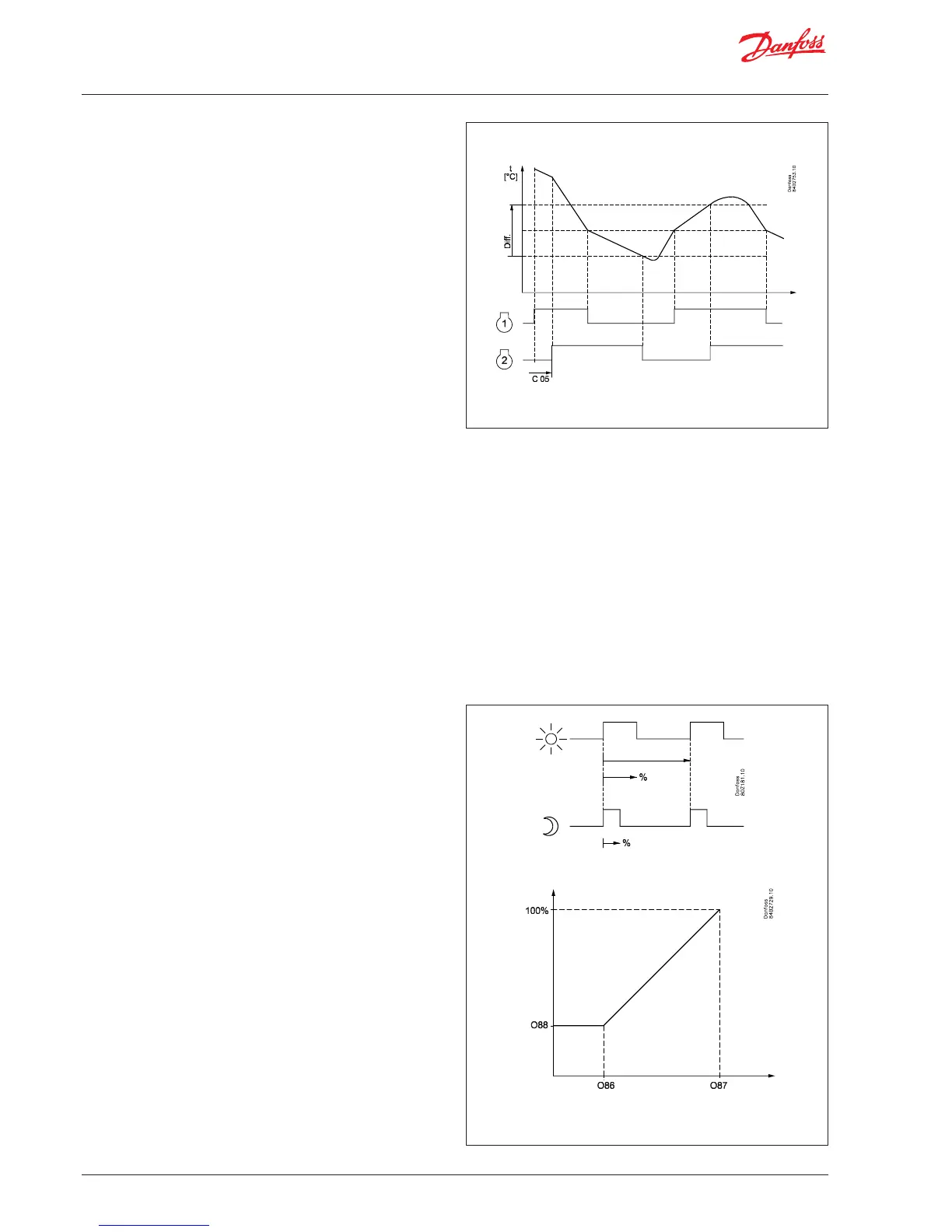

Pulse control according to day and night

Various ON periods can be set for day and night operation.

A period time is set as well as the percentage part of the period in

which the rail heat is ON.

Pulse control according to dew point

In order to use this function a system manager of the type AK-SM

is required which can measure dew point and distribute the cur-

rent dew point to the appliance controllers. For this the rail heat’s

ON period is controlled from the current dew point.

Two dew point values are set in the appliance control:

• One where the eect must be max. i.e.100%. (o87)

• One where the eect must be min. (o86).

At a dew point which is equal to or lower than the value in 086,

the eect will be the value indicated in o88.

In the area between the two dew point values the controller will

manage the power to be supplied to the rail heat.

During defrosting

During defrosting the rail heat will be controlled by the setting in

"d27" (O, On or pulsing).

Dew point

Rail heat

Loading...

Loading...