Data sheet PAH 2/4/6.3, PAH 10/12.5, PAH 20/25/32 and PAH 50/63/70/80/100 pumps

26 | 180R9379 | AQ188686503004en-000801 | PAH 2-12.5

© Danfoss | DCS (im) | 2022.07

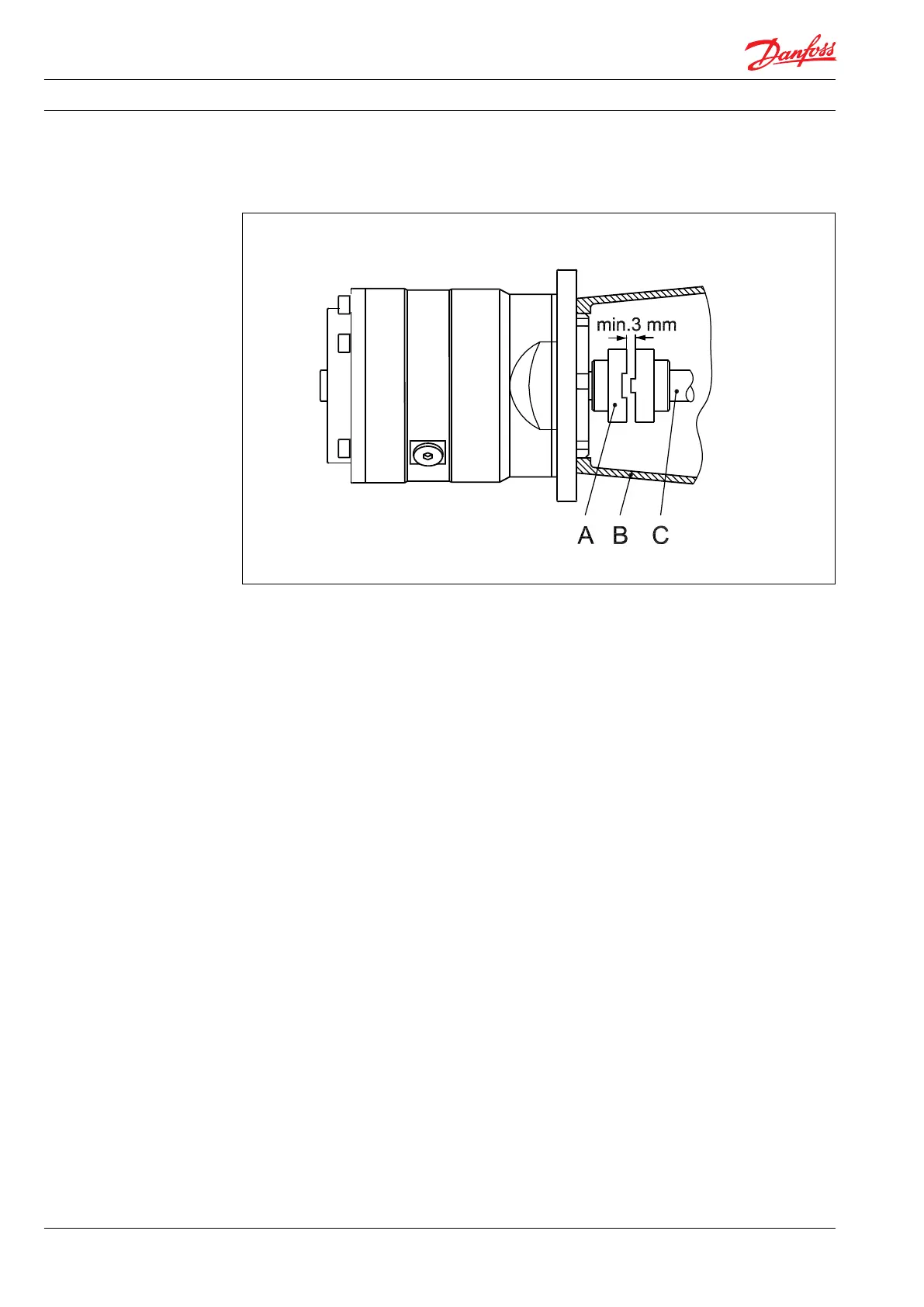

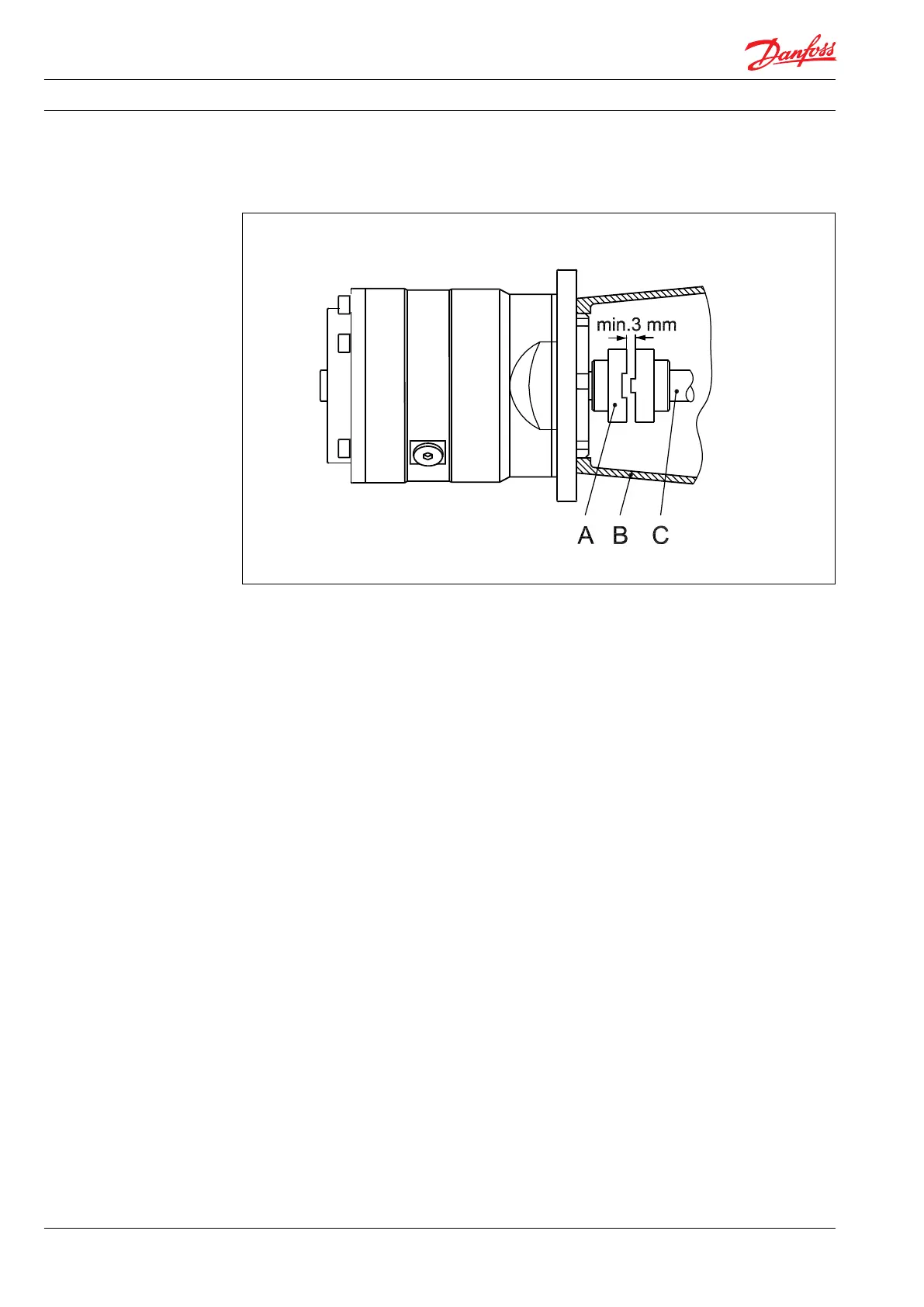

7. Installation See the gure below for instructions on how to

mount the pump and connect it to an electric

motor or combustion engine.

If alternative mounting is required, please

contact your Danfoss sales representative for

further information.

Note: Do not add any axial or radial loads to the

pump shaft.

7.1 Filtration

Proper ltration is crucial for the performance,

maintenance and warranty of your pump.

Protect your pump, and the application in which

it is installed, by always ensuring that ltration

specications are met, and by always changing

lter cartridges according to schedule.

Since water has very low viscosity, Danfoss PAH

pumps have been designed with very narrow

clearances in order to control internal leakage

rates and improve component performance. To

minimize wear in the pump, it is therefore

essential to lter inlet water properly.

The main lter must have a ltration eciency

of 99.98% at 10 μm. We strongly recommend

that you always use precision depth lter

cartridges rated 10 μm abs. β

10

≥ 5,000.

Please note that we do not recommend bag

lters or string-wound lter cartridges, which

typically have only 50% ltration eciency. This

means that out of 100,000 particles that enter

such lters, 50,000 particles pass right through

them; compare this to precision depth lters that

are 99.98% ecient, and only allow 20 of the

same 100,000 particles to pass through.

For more information on the importance of

proper ltration, including explanation of

ltration principles, denitions, and guidance on

how to select the right lter for your pump,

please consult our Filtration information and

specications (Danfoss document number

521B1009).

7.2 Noise

Since the pump unit is mounted on a frame, the

overall noise level can only be determined for a

complete system. To minimize vibrations and

noise throughout the system, it is therefore very

important to mount the pump unit correctly on a

frame with dampers and to use exible hoses

rather than metal pipes where possible.

The noise level is inuenced by:

• Pump speed:

High rpm makes more uid/structure-

borne pulsations/vibrations than low rpm.

• Discharge pressure:

High pressures make more noise than low

pressures.

• Pump mounting:

Rigid mounting makes more noise than

exible mounting because of the structure-

borne vibrations. Be sure to use dampers

when mounting.

• Connections to pump:

Pipes connected directly to the pump make

more noise than exible hoses because of

structure-borne vibrations.

• Variable frequency drives (VFDs):

Motors regulated by VFDs can produce

more noise if the VFD does not have the

right settings.

A: Flexible coupling

B: Bell housing

C: Motor shaft

Loading...

Loading...