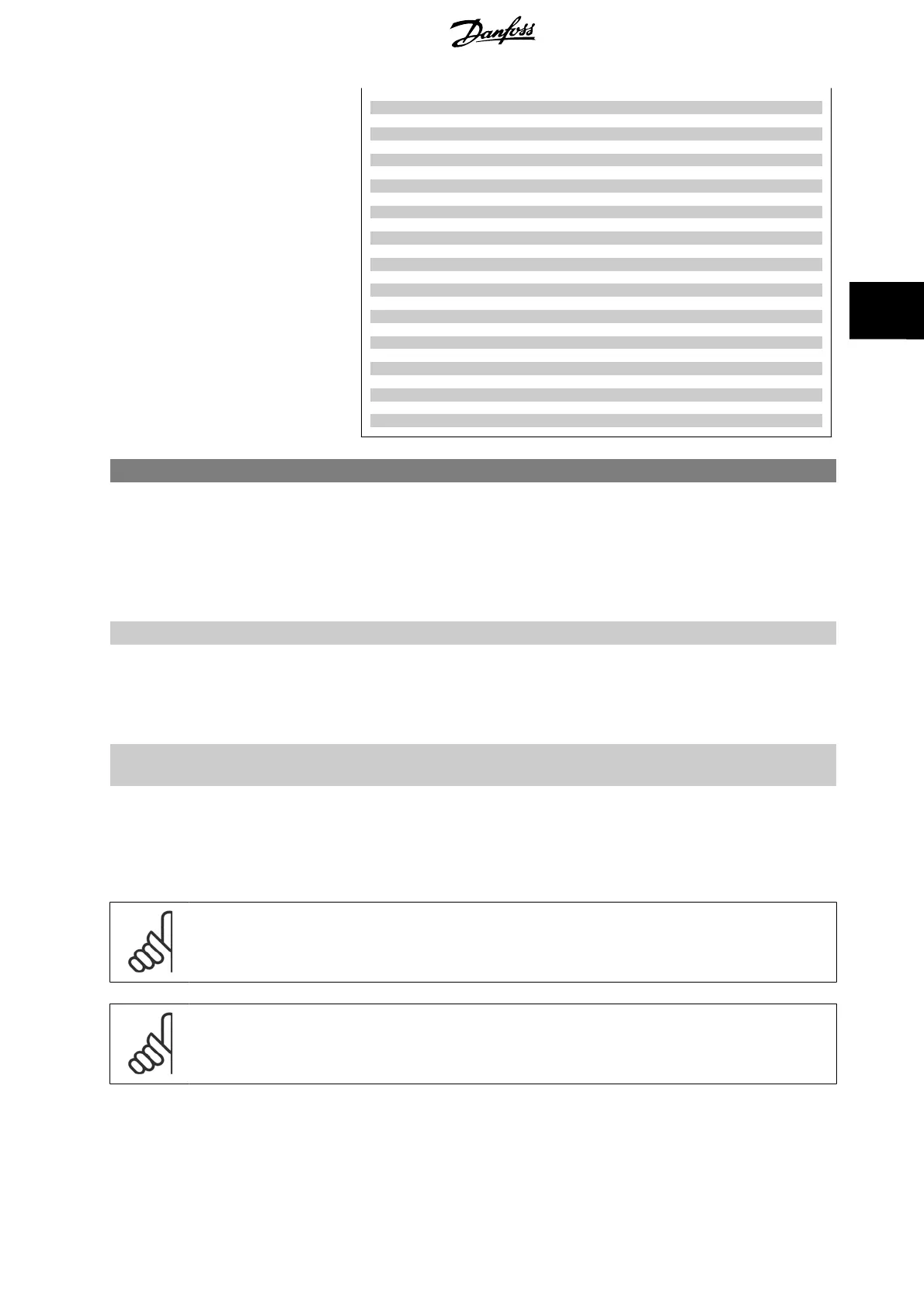

Latched start [9]

Reversing [10]

Start reversing [11]

Enable start forward [12]

Enable start reverse [13]

Jog [14]

Preset ref bit 0 [16]

Preset ref bit 1 [17]

Preset ref bit 2 [18]

Freeze reference [19]

Freeze output [20]

Speed up [21]

Speed down [22]

Set-up select bit 0 [23]

Set-up select bit 1 [24]

Catch up [28]

Slow down [29]

Pulse input [32]

Ramp bit 0 [34]

Ramp bit 1 [35]

Mains failure inverse [36]

DigiPot Increase [55]

DigiPot Decrease [56]

DigiPot Clear [57]

Reset Counter A [62]

Reset Counter B [65]

1-29 Automatic Motor Adaptation (AMA)

Option: Function:

The AMA function optimizes dynamic motor performance by automatically optimizing the advanced

motor parameters (par. 1-30 to par. 1-35) at motor standstill.

Activate the AMA function by pressing [Hand on] after selecting [1] or [2]. See also the section

Automatic Motor Adaptation

. After a normal sequence, the display will read: "Press [OK] to finish

AMA". After pressing the [OK] key the frequency converter is ready for operation.

This parameter cannot be adjusted while the motor is running.

[0] * OFF

[1] Enable complete AMA Performs AMA of the stator resistance R

S

, the rotor resistance R

r

, the stator leakage reactance X

1

,

the rotor leakage reactance X

2

and the main reactance X

h

.

FC 301: The complete AMA does not include X

h

measurement for FC 301. Instead, the X

h

value is

determined from the motor database. Par. 1-35 may be adjusted to obtain optimal start perform-

ance.

[2] Enable reduced AMA Performs a reduced AMA of the stator resistance R

s

in the system only. Select this option if an LC

filter is used between the drive and the motor.

Note:

• For the best adaptation of the frequency converter, run AMA on a cold motor.

• AMA cannot be performed while the motor is running.

• AMA cannot be performed on permanent magnet motors.

NB!

It is important to set motor par. 1-2* correctly, since these form part of the AMA algorithm. An AMA must be performed to achieve

optimum dynamic motor performance. It may take up to 10 min, depending on the power rating of the motor.

NB!

Avoid generating external torque during AMA.

VLT

®

AutomationDrive FC 300 Operating

Instructions

4 How to Programme

MG.33.AG.02 - VLT

®

is a registered Danfoss trademark

47

4

Loading...

Loading...